You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

And.......here's one I made earlier.

- Thread starter whiskywill

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Claud1

Established Member

must have plenty of time on his hands

LancsRick

Established Member

You can give me all the time you want and I wouldn't produce that, outstanding.

custard

Established Member

LancsRick":16l2y569 said:You can give me all the time you want and I wouldn't produce that, outstanding.

I appreciate there's some self-disparaging humour there Rick, but it still pains me to hear that.

Work of that quality doesn't come easily, but neither is it supernatural. You, and indeed most people on this forum, absolutely could do that.

Part of the problem is that people increasingly learn about woodworking from YouTube, and the limited attention span of the internet means they get a very misleading impression of how long first rate work actually takes. They see all these videos which have been edited down to the bare minimum, with much of the time consuming stuff left on the cutting room floor and other parts speeded up to keep the viewer's attention.

But if you trained at the Robinson House Studio, or any other workshop doing work of that quality, you'd realise that top end woodworking proceeds at a snail's pace, with each meticulous step conducted with an almost zen like patience and deliberation. Part of the secret of good craftsmanship is to pretty much ignore the end result, and instead focus 100% of your attention on the immediate task in hand. But that's anathema in a world of instant gratification and quick results.

The trickiest part of cutting the joint in that video is the compound angled saw cut. But a similar saw cut is required for the mitred dovetails discussed here,

how-to-cut-mitred-or-mitre-dovetails-wip-t112467.html

If you read through to the end you see Tyreman, who is self taught and relatively new to woodworking, had a go and, because he's a naturally methodical and patient sort of bloke, he produced a very creditable result. I've no doubt that he could also pull off this joint too, as could anyone who can get themselves into that same calm and deliberate craftsman's head space.

Incidentally, here's Theo Cook's video on how he actually cuts that particular joint, I wish he'd stated the normal completion time for a relative newbie, if you include the jigs and templates then my guess is around 20-25 hours. But watching his video you might assume that if you can't get it done inside of about two or three hours then you're doing something wrong!

https://www.youtube.com/watch?v=0I4daFL ... gs=pl%2Cwn

John15

Established Member

Extremely skilled work but I don't find it attractive. The simpler dovetails are much easier on the eye in my opinion.

John

John

thetyreman

Established Member

must admit that robinson house studio looks like an amazing place to learn, thanks for the praise custard, ideally I'd like to use the mitred dovetail on something like a jewellery box, the japanese dovetail is another level of precision though, might have to work my way up to that level yet!

Robbo3

Established Member

That's mind boggling.

I have a neighbour who won't talk to me because he can't believe how bad I am - unless he wants to borrow something.

You obviously haven't come across somebody like me. I got kicked out of woodworking at school for being so bad & I haven't improved much in the 50 years since. That's why I took up wood turning but I'm not much better at that.custard":1qsrayog said:Work of that quality doesn't come easily, but neither is it supernatural. You, and indeed most people on this forum, absolutely could do that.

I have a neighbour who won't talk to me because he can't believe how bad I am - unless he wants to borrow something.

Another point when thinking about the skill and time that it takes - it won't be perfect if the marking out isn't, and that in itself isn't easy.

Sgian Dubh

Established Member

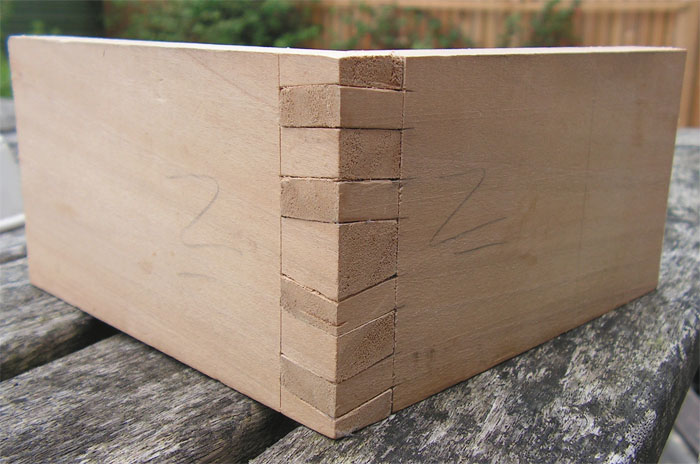

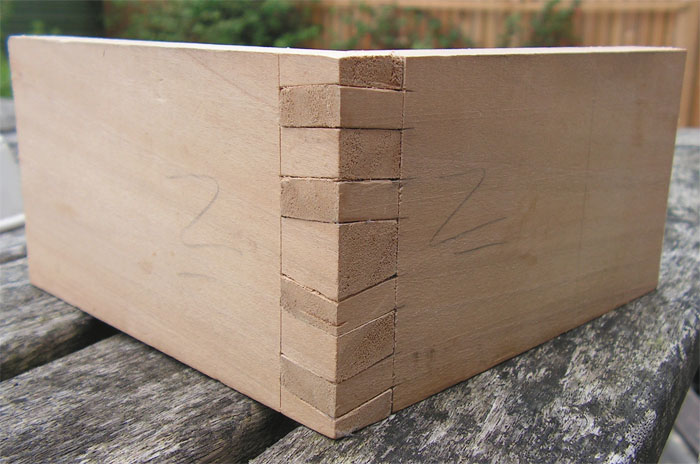

I've made a few of this type of joint, a couple of times used in furniture, and a few more times as demonstration pieces. I first came across what I call the double twisted dovetail some time back in the early 1980s, but at that time all I'd heard as a description was there was a dovetail joint 'out there' that locked in both directions simultaneously. I didn't think much more about it, but then one day, probably around the late 80s I began to toy with the idea and a possible method of execution started to come to mind, so I piddled about with some bits of wood until I worked out how to do it. It was only some years later I realised I'd basically reinvented the wheel and the Japanese had got the technique sorted ages ago, and had a name for it which even now I can't recall. My excuse is there was no internet back them and I was either too busy or not initially interested enough to go trawling through books, magazines and anything I could find in libraries to see if such an 'impossible' joint could exist.

Anyway, here's an example I cut a year or two back as a demonstration for some learners I was teaching. It probably took about an hour or hour and a bit to cut. As you can see, it's a bit hurried and not as well executed as it could have been, but that's what happens when you quickly hash bash the job. It also doesn't help that it has probably been assembled and disassembled scores of times before I got round to taking a photograph. And you'll notice the rake or slope of the tails/pins is nowhere near as extreme as those executed by Theo Cook which means my version is significantly more robust than his which I suppose lets me be a bit more cavalier and heavy handed than he needed to be to cut his examples.

As to aesthetic appeal, I quite like them, but the joint's not one I'd use on a regular basis in my furniture. If anyone's interested in learning how to cut the joint here's a link to an article I wrote about it nearly twenty years ago, and another link to more images of the sample joint below. Slainte.

Anyway, here's an example I cut a year or two back as a demonstration for some learners I was teaching. It probably took about an hour or hour and a bit to cut. As you can see, it's a bit hurried and not as well executed as it could have been, but that's what happens when you quickly hash bash the job. It also doesn't help that it has probably been assembled and disassembled scores of times before I got round to taking a photograph. And you'll notice the rake or slope of the tails/pins is nowhere near as extreme as those executed by Theo Cook which means my version is significantly more robust than his which I suppose lets me be a bit more cavalier and heavy handed than he needed to be to cut his examples.

As to aesthetic appeal, I quite like them, but the joint's not one I'd use on a regular basis in my furniture. If anyone's interested in learning how to cut the joint here's a link to an article I wrote about it nearly twenty years ago, and another link to more images of the sample joint below. Slainte.

doctor Bob

Established Member

- Joined

- 22 Jun 2011

- Messages

- 5,171

- Reaction score

- 1,881

Yes virtually the same joint, it's very hard to see any difference.

Sgian Dubh":7r35ct4w said:

Loldoctor Bob":3jz2m8hx said:Yes virtually the same joint, it's very hard to see any difference.

Sgian Dubh":3jz2m8hx said:

Sent from my Nexus 5X using Tapatalk

Sgian Dubh

Established Member

Ha, ha. No flies on you there Bob demonstrating exceptional eyesight for being able to see slight differences in form and quality of execution, although the general method of working and assembly of the joints are obviously much the same. A bit more attempt at accuracy and neatness did go in to the one below though - it also took a bit longer to work and put together. Slainte.doctor Bob":2p6k4w0g said:Yes virtually the same joint, it's very hard to see any difference.

Raymond UK

Established Member

Wow, that's some fantastic dovetailing.

Similar threads

- Replies

- 1

- Views

- 201

- Replies

- 0

- Views

- 510