I'm building a guest house in my garden with a shed attached. I was only intending to have a shed, but while enjoying building the whole thing (and discovering this forum) I've found myself wanting to learn some woodworking skills, and have a bit of a workshop. But I've only realised this now that it's nearly finished, and I wish I'd made the shed wider (although that would mean having the guest house thinner which wouldn't be ideal either).

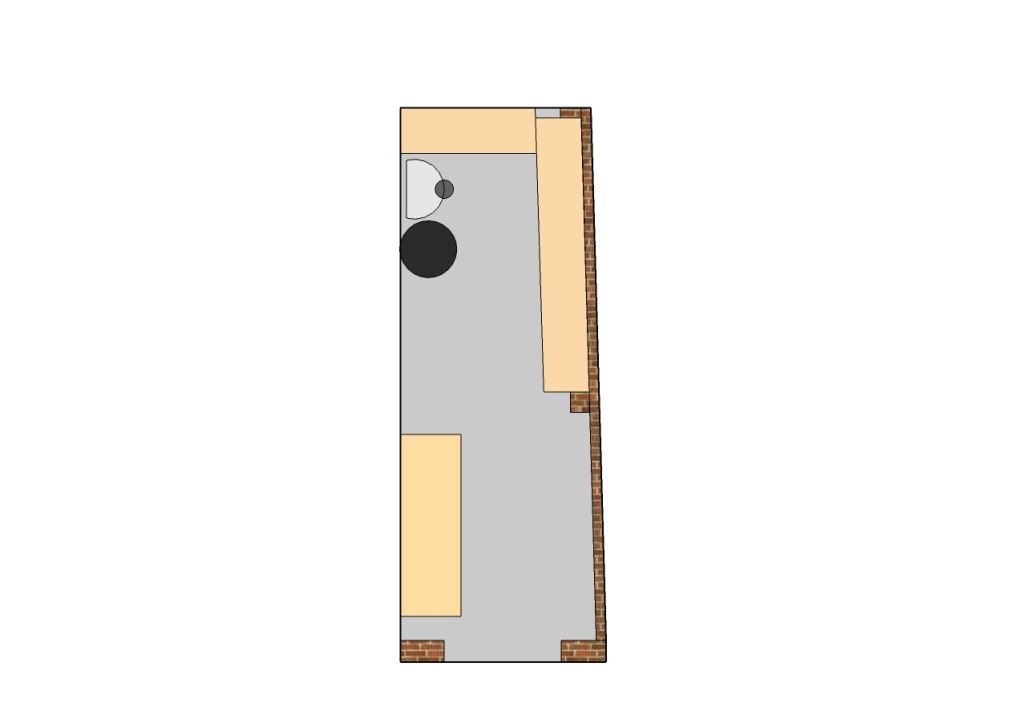

So here I am with a storage shed that's 5.3m x 1.8/1.95m (it tapers) that I'd like to use as a workshop too. For the purpose of this thread I've just downloaded sketchup and had a go at drawing it, with a start of my planned layout:

The sketch shows storage shelves (450mm deep) along the back wall, and then down the right hand wall. My wheel barrow and a stack of car wheels (they have to go somewhere). The double doors to the shed are at the bottom, and just to the left as you walk in seems like a sensible place for a workbench (not sure how big, but the one I've drawn there is 1.8m x 0.6m). I'd like to hang my electric lawnmower and other gardening tools opposite the workbench, I just haven't tried sketching those.

I would like to learn some woodworking skills with the intention of being able to make simple things like nice shelving and bookshelves (I have lots of reclaimed oak flooring), so it may be nice in the future to have something like a mobile bandsaw in there. I'm not sure if there there is room for a mobile table saw that could work with a similar height workbench and the open doors - even though I wouldn't be getting such equipment until I'd finished some small projects and learnt some skills, it'd be nice to hear your thoughts on whether this small space could accommodate much, and plan it out now before I embark on the workbench build.

Any suggestions would be appreciated, thanks

So here I am with a storage shed that's 5.3m x 1.8/1.95m (it tapers) that I'd like to use as a workshop too. For the purpose of this thread I've just downloaded sketchup and had a go at drawing it, with a start of my planned layout:

The sketch shows storage shelves (450mm deep) along the back wall, and then down the right hand wall. My wheel barrow and a stack of car wheels (they have to go somewhere). The double doors to the shed are at the bottom, and just to the left as you walk in seems like a sensible place for a workbench (not sure how big, but the one I've drawn there is 1.8m x 0.6m). I'd like to hang my electric lawnmower and other gardening tools opposite the workbench, I just haven't tried sketching those.

I would like to learn some woodworking skills with the intention of being able to make simple things like nice shelving and bookshelves (I have lots of reclaimed oak flooring), so it may be nice in the future to have something like a mobile bandsaw in there. I'm not sure if there there is room for a mobile table saw that could work with a similar height workbench and the open doors - even though I wouldn't be getting such equipment until I'd finished some small projects and learnt some skills, it'd be nice to hear your thoughts on whether this small space could accommodate much, and plan it out now before I embark on the workbench build.

Any suggestions would be appreciated, thanks