jimi43

Established Member

I received my TATHS membership pack this week...wonderful!!!

Part of the deal is the Seaton Chest book which as you may know...is free with the membership.

There is a page showing all the Gabriel planes in the form of a letter "S"

When I saw this I decided that if I'm going to collect ( ) woodies, I might as well collect Gabriels and start with the No.1 I recently bought...add to that this next one...and go from there.

) woodies, I might as well collect Gabriels and start with the No.1 I recently bought...add to that this next one...and go from there.

So over to the latest acquisition....

This one's a FleaBay restoration project...

It has an old (very old) extension to the side...which was broken...

...which virtually fell off...leaving a few ancient tacks which easily pulled out...

The keen-eyed amongst you will notice also a bleedin' huge lump of boxwood insert missing to the front of the main profile curve of the iron....mmmmm

There are also a few flight holes from prehistoric beasties....

...long since flown the nest I think!

I have some boxwood which would suit but I need a round of the right size to make the profile...or I might make a scratch...depending on which comes first! I started out by raiding the kitchen drawers...for cocktail sticks...

...to prevent their descendants from coming back to roost! :mrgreen:

The tips were then stained and matched perfectly.

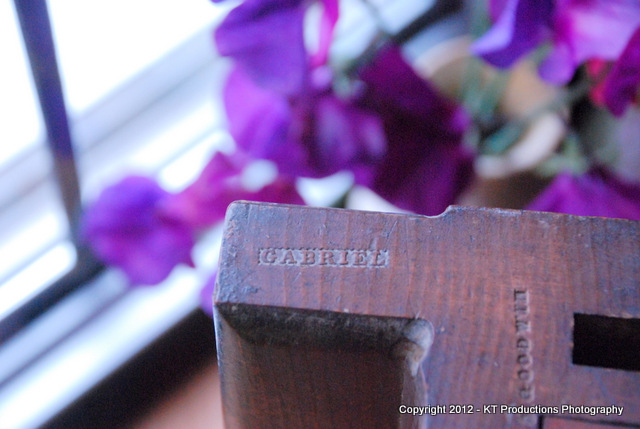

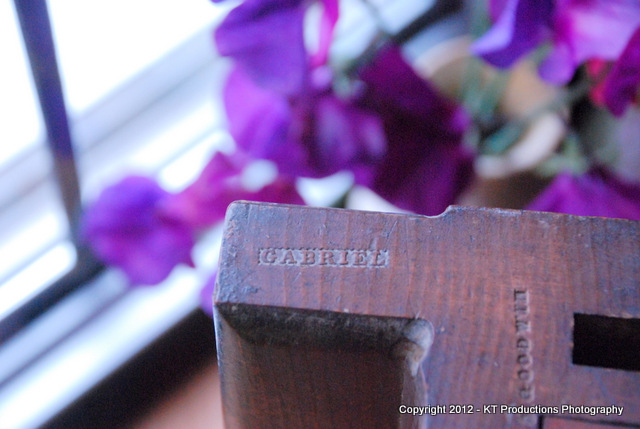

I've become rather attached to the beautiful ZB (zigzag border) of the maker's mark...

...from that bygone era....but this one is even more fascinating as there are a couple of contemporary owner's stamps on the other end...

One has been virtually obliterated but I am working a bit of forensics on that...the other is clear as a bell...a Mr J.Bedwell which may be John Bedwell, carpenter of Pound Street London...later of Ipswich. It's about the right date but we may never know.

Still...another part of the Jimi Chest is nearly there...the iron honed and ready to go once I get the insert sorted.

I am glad I have focussed this slope to one maker....this could become quite addictive!.....Mind you...there is a nice Griffiths up for sale at the moment!

Jim

Part of the deal is the Seaton Chest book which as you may know...is free with the membership.

There is a page showing all the Gabriel planes in the form of a letter "S"

When I saw this I decided that if I'm going to collect (

So over to the latest acquisition....

This one's a FleaBay restoration project...

It has an old (very old) extension to the side...which was broken...

...which virtually fell off...leaving a few ancient tacks which easily pulled out...

The keen-eyed amongst you will notice also a bleedin' huge lump of boxwood insert missing to the front of the main profile curve of the iron....mmmmm

There are also a few flight holes from prehistoric beasties....

...long since flown the nest I think!

I have some boxwood which would suit but I need a round of the right size to make the profile...or I might make a scratch...depending on which comes first! I started out by raiding the kitchen drawers...for cocktail sticks...

...to prevent their descendants from coming back to roost! :mrgreen:

The tips were then stained and matched perfectly.

I've become rather attached to the beautiful ZB (zigzag border) of the maker's mark...

...from that bygone era....but this one is even more fascinating as there are a couple of contemporary owner's stamps on the other end...

One has been virtually obliterated but I am working a bit of forensics on that...the other is clear as a bell...a Mr J.Bedwell which may be John Bedwell, carpenter of Pound Street London...later of Ipswich. It's about the right date but we may never know.

Still...another part of the Jimi Chest is nearly there...the iron honed and ready to go once I get the insert sorted.

I am glad I have focussed this slope to one maker....this could become quite addictive!.....Mind you...there is a nice Griffiths up for sale at the moment!

Jim