You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How was this cut?

- Thread starter Chris152

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Myfordman

AKA 9Fingers

Easy enough to mass produce with a comb joint cutter on a spindle on a chunck of timber and then slice into 5mm thick slices

As a one off? not so easy.

As a one off? not so easy.

Woody2Shoes

Impressive Member

Easy to do with a scrollsaw - that's how I made one a while back.

Cheers, W2S

Cheers, W2S

On comb joint cutter I found these:

Certainly don't have the kit to run those;

and

not deep enough and can't find it in the UK.

To do the cuts with a scroll saw, would you use a jig to get cuts parallel? And what's a reasonable depth to cut on a scroll saw - could you do a few 5mm thicknesses together? (I've never used a scroll saw.)

Certainly don't have the kit to run those;

and

not deep enough and can't find it in the UK.

To do the cuts with a scroll saw, would you use a jig to get cuts parallel? And what's a reasonable depth to cut on a scroll saw - could you do a few 5mm thicknesses together? (I've never used a scroll saw.)

Attachments

Inspector

Nyuck, Nyuck, Nyuck!

A good saw sharpener could regrind/re-tooth a table saw blade(rip) to cut a single V notch. You would then have to move the comb over finger joint style to cut the rest. Not worth it to make one but for small batches good. For large scale production it is shaper time.

Pete

Pete

novocaine

Established Member

combs are normally stamped out (big scary funny bladed guillotine) or comb cut as suggested, when mass produced.

no chance you are going to cut it with a comb cutter over more than 1" of width so that's out (home shop).

scroll saw, you could stack maybe 3 at a time and with a bit of practice you'll be close to accurate (certainly enough for a wax comb). I might have a go with some scrap if I get chance in the shop this week to see how it goes.

you could do the say with a fret/piercing saw and a pin, it's going to take you a while but it's doable.

If you want to improve accuracy make a pin jig (like you'd use for bookcase shelf pins but smaller) and drill the bottom of each tine with a small hole to give you a target.

theres a guy in cornwall (can't remember where I saw him, it might of been Bude) that makes them from driftwood and skateboard decks (1 comb, both materials) that cuts them by hand, he has bigger teeth to make it a bit easier), think they were about a fiver when I saw them. oh, the point of this story, he uses a zero set saw (like a flush cut) and a metal guide to get it accurate.

no chance you are going to cut it with a comb cutter over more than 1" of width so that's out (home shop).

scroll saw, you could stack maybe 3 at a time and with a bit of practice you'll be close to accurate (certainly enough for a wax comb). I might have a go with some scrap if I get chance in the shop this week to see how it goes.

you could do the say with a fret/piercing saw and a pin, it's going to take you a while but it's doable.

If you want to improve accuracy make a pin jig (like you'd use for bookcase shelf pins but smaller) and drill the bottom of each tine with a small hole to give you a target.

theres a guy in cornwall (can't remember where I saw him, it might of been Bude) that makes them from driftwood and skateboard decks (1 comb, both materials) that cuts them by hand, he has bigger teeth to make it a bit easier), think they were about a fiver when I saw them. oh, the point of this story, he uses a zero set saw (like a flush cut) and a metal guide to get it accurate.

Inspector - so far I've avoided table saws almost completely, I reckon cutting individual teeth would be challenging for me (just the noise of the teeth cutting through the air in the workshop worries me!).

I've had to look up four terms just to try to keep up with that post!

The handmade ones in Cornwall sound interesting and possibly do-able by me - the guide would be like one of those magnetic dovetail guides you can buy but at a steeper angle?

If you do get a chance on a scroll saw it'd be good to know how you get on.

hmmm...

https://www.alibaba.com/product-detail/ ... 2228q6nCKi

!

novocaine":2bu9qsft said:combs are normally stamped out (big scary funny bladed guillotine) or comb cut as suggested, when mass produced.

no chance you are going to cut it with a comb cutter over more than 1" of width so that's out (home shop).

scroll saw, you could stack maybe 3 at a time and with a bit of practice you'll be close to accurate (certainly enough for a wax comb). I might have a go with some scrap if I get chance in the shop this week to see how it goes.

you could do the say with a fret/piercing saw and a pin, it's going to take you a while but it's doable.

If you want to improve accuracy make a pin jig (like you'd use for bookcase shelf pins but smaller) and drill the bottom of each tine with a small hole to give you a target.

theres a guy in cornwall (can't remember where I saw him, it might of been Bude) that makes them from driftwood and skateboard decks (1 comb, both materials) that cuts them by hand, he has bigger teeth to make it a bit easier), think they were about a fiver when I saw them. oh, the point of this story, he uses a zero set saw (like a flush cut) and a metal guide to get it accurate.

I've had to look up four terms just to try to keep up with that post!

The handmade ones in Cornwall sound interesting and possibly do-able by me - the guide would be like one of those magnetic dovetail guides you can buy but at a steeper angle?

If you do get a chance on a scroll saw it'd be good to know how you get on.

hmmm...

https://www.alibaba.com/product-detail/ ... 2228q6nCKi

!

I searched yesterday and found a jig used for making wooden combs (like the one used here at 1'19": https://www.youtube.com/watch?v=BTxY4ljMBn8) - it's like the ones used for making box joints on a router or bandsaw. I wondered if you angled the jig to cut one way, then used another angled the other way, it'd work.ColeyS1":ni86mn46 said:I was thinking about this yesterday and figured if I was going to do it I'd probably use the bandsaw and a jig.

Inspector

Nyuck, Nyuck, Nyuck!

I could joke and tell you to use ear plugs and ear muffs so you don't hear the table saw blade but if you aren't comfortable with it then you shouldn't use one. They are one of the most versatile machines in the shop and I wouldn't be without one. Actually I have two. :roll:

There is an expensive option that would be perfect for doing that kind of work and doesn't have a noisy blade or motor for that matter. It was originally made by Bridge City Tools but has since been sold to Harvey Tools in China. They are sold here by Lee Valley and there may be a seller in the UK you could turn to if you wanted to go that route.

https://www.leevalley.com/en-ca/shop/to ... tmaker-pro

Here is a video Bridge City did when they came up with the tool.

https://www.youtube.com/watch?v=3ruwZdaPjbs

Pete

Added. https://harveymachinery.com/bctw/jointmaker-pro/

Axminster sell some of their tools and might bring them in if asked.

https://www.axminster.co.uk/bridge-city

There is an expensive option that would be perfect for doing that kind of work and doesn't have a noisy blade or motor for that matter. It was originally made by Bridge City Tools but has since been sold to Harvey Tools in China. They are sold here by Lee Valley and there may be a seller in the UK you could turn to if you wanted to go that route.

https://www.leevalley.com/en-ca/shop/to ... tmaker-pro

Here is a video Bridge City did when they came up with the tool.

https://www.youtube.com/watch?v=3ruwZdaPjbs

Pete

Added. https://harveymachinery.com/bctw/jointmaker-pro/

Axminster sell some of their tools and might bring them in if asked.

https://www.axminster.co.uk/bridge-city

Amazing piece of kit - if only they'd move the decimal point on the price one place to the left! I wonder if you could make a version of that with just two angled settings for simplicity. Definitely worth a go!

novocaine

Established Member

I can see a mitre fence and maybe a little jig in your future. making cavity covers for guitar tonight. Will play with an offcut hopefully tomorrow on the band saw and the scroll saw.

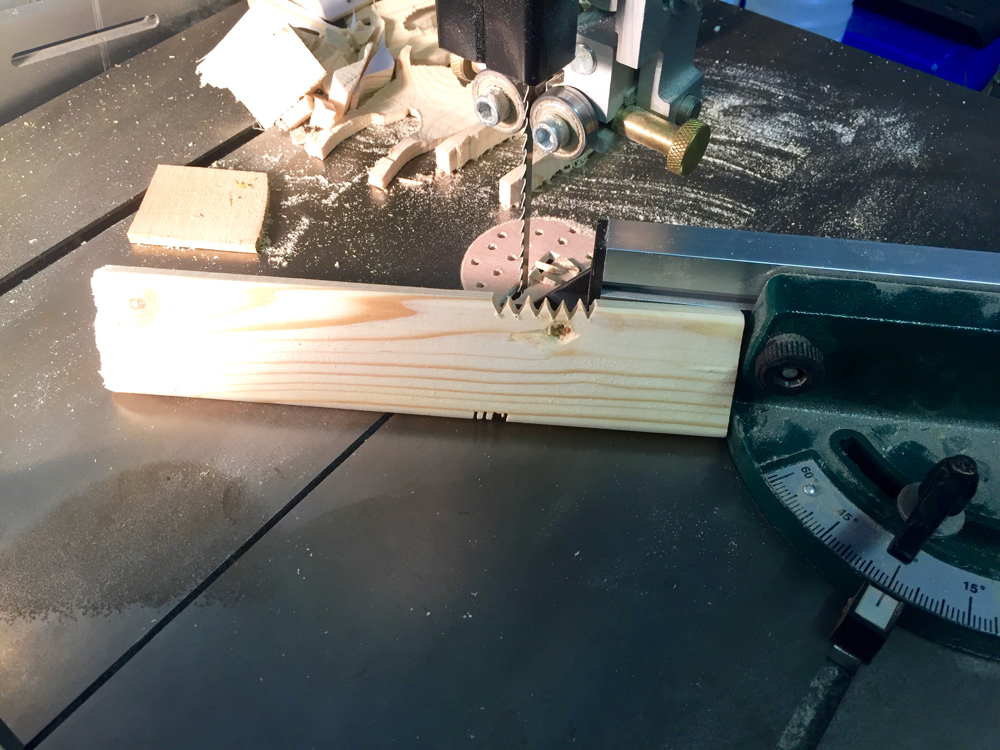

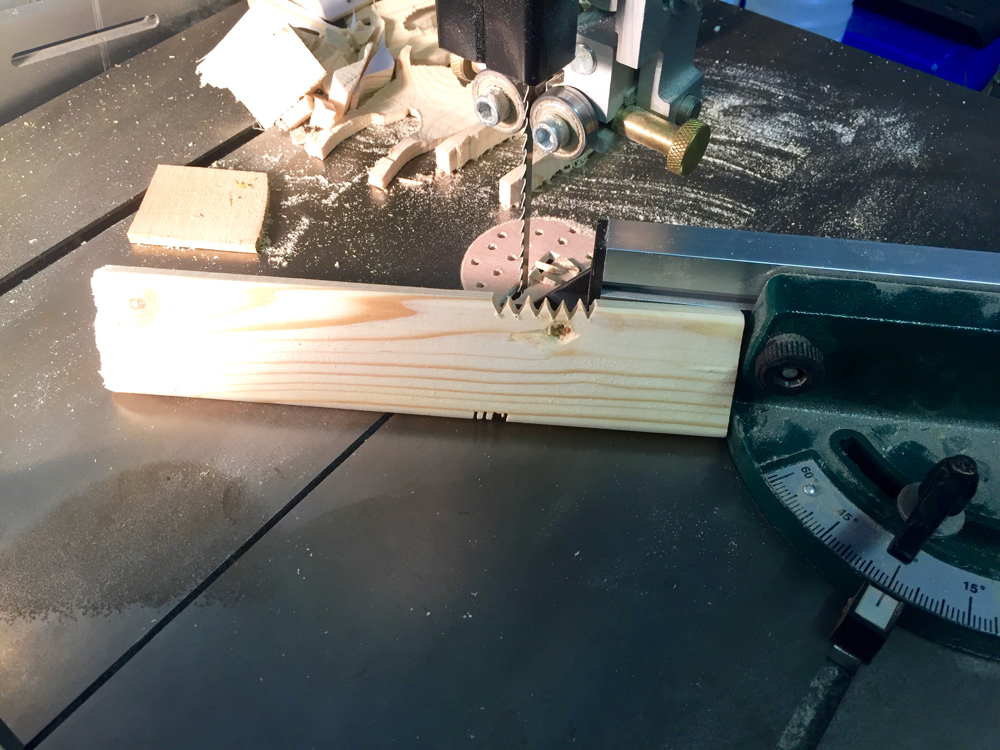

Thanks novocaine - haven't used the mitre guide since I bought the saw, didn't even occur to me! This is done by eye and the mitre guide on 30 degrees without markings or stops but I can see that it could work fine - especially with a thinner blade with minimum set, producing a thinner gap between the teeth of the comb (these are about 5mm). It'll need either a lot of care or some kind of stop to ensure all the teeth are the same length (some of these wouldn't touch the surface).

Front and back will be sanded to bring the teeth closer to a point (about 3mm depth remaining at the tips).

Front and back will be sanded to bring the teeth closer to a point (about 3mm depth remaining at the tips).

Attachments

novocaine

Established Member

yep that works.

I think what I'd do is make a jig that rides on the mitre slot instead of using the fence.

A piece thats 18x400x60 fit a runner to the base of it so sits at the 30 degrees mark and extends a good 100mm past the blade. you can then do a small initial cut in the front of it to the depth you want the teeth to be (about 10mm so you get a bit of extra). from that mark out each cut across the jig, you can drill holes and put pins in if you want so you move the pins each cut and have something to register against.

this needs a drawing. just a mo.

something like that. if you feel comfortable with registering against lines you don't need the registration holes. or you could incorporate the holes in to the design of you comb so you slot 2 pins in the comb, cut it out, flip it, do the same then claim the holes are for lanyards.

I think what I'd do is make a jig that rides on the mitre slot instead of using the fence.

A piece thats 18x400x60 fit a runner to the base of it so sits at the 30 degrees mark and extends a good 100mm past the blade. you can then do a small initial cut in the front of it to the depth you want the teeth to be (about 10mm so you get a bit of extra). from that mark out each cut across the jig, you can drill holes and put pins in if you want so you move the pins each cut and have something to register against.

this needs a drawing. just a mo.

something like that. if you feel comfortable with registering against lines you don't need the registration holes. or you could incorporate the holes in to the design of you comb so you slot 2 pins in the comb, cut it out, flip it, do the same then claim the holes are for lanyards.

Attachments

That looks great - my feeling is I'll do better at first go with just accurate lines to work to, drilling one hole slightly in the wrong place would result in a dud tooth/ having to remake the jig. I'm off hunting for wood today so it'll have to wait, but meantime I'll put an order in for a new blade as above. I'm thinking to make them from oak, ash or beech (i have plenty of offcuts), cutting into end grain for strength of the teeth - sound ok?

Thanks for the drawing novocaine, really appreciate it.

Thanks for the drawing novocaine, really appreciate it.

novocaine

Established Member

dont use oak. sea water and oak aren't best of friends (someone will tell you about their oak boat and how it's never been an issue shortly).

white woods like ash and beach are a good choice IMHO, found the guy (who appears to to be 2 girls now) in cornwall on etsy (who knew)

duuuuuuuuude

drilling holes accurately, you make a jig for that. a block with four holes drilled perfectly (only need to get 4 right). a pin in 2 of the holes and the other 2 are the guide. drill the first 2 holes in your comb jib, insert the drilling jig and drill the next 2, then advance the drilling jig to those holes and repeat.

a block with four holes drilled perfectly (only need to get 4 right). a pin in 2 of the holes and the other 2 are the guide. drill the first 2 holes in your comb jib, insert the drilling jig and drill the next 2, then advance the drilling jig to those holes and repeat.

white woods like ash and beach are a good choice IMHO, found the guy (who appears to to be 2 girls now) in cornwall on etsy (who knew)

duuuuuuuuude

drilling holes accurately, you make a jig for that.

Similar threads

- Replies

- 9

- Views

- 423

- Replies

- 13

- Views

- 1K