Having recently moved, I find myself without a workshop and with a long list of jobs to do around the house so it made a nice change to fit in a little bit of tool fiddling this weekend:

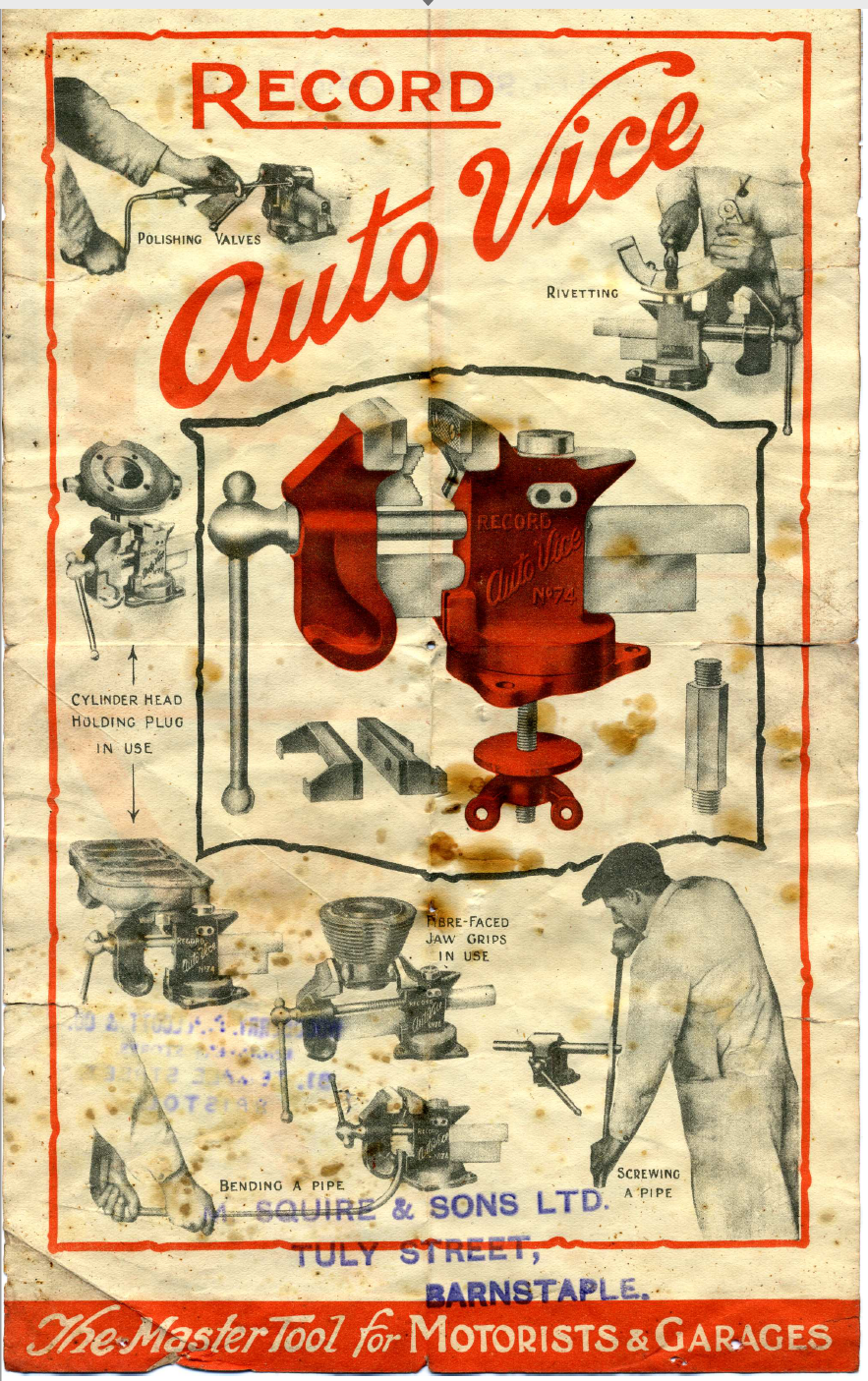

A record 74 vice - a bit grotty but in good condition, the only minor issue being that at some point the pin that retains the washer/spring used to hold the handle against the moveable jaw had broken and the washer bent as a result. Once extracted a few whacks with a hammer got it back into shape, and an old nail did as a replacement pin.

Having got it apart a bit of elbow grease to remove 80 years of accumulated oil and grease plus various layers of paint (not sure why it was partly painted green - perhaps to distinguish it from others in a shared workshop?) and it looked like this:

more thrills to come!

*edits to fix photos

A record 74 vice - a bit grotty but in good condition, the only minor issue being that at some point the pin that retains the washer/spring used to hold the handle against the moveable jaw had broken and the washer bent as a result. Once extracted a few whacks with a hammer got it back into shape, and an old nail did as a replacement pin.

Having got it apart a bit of elbow grease to remove 80 years of accumulated oil and grease plus various layers of paint (not sure why it was partly painted green - perhaps to distinguish it from others in a shared workshop?) and it looked like this:

more thrills to come!

*edits to fix photos