henton49er

Established Member

Please post your entries on this thread

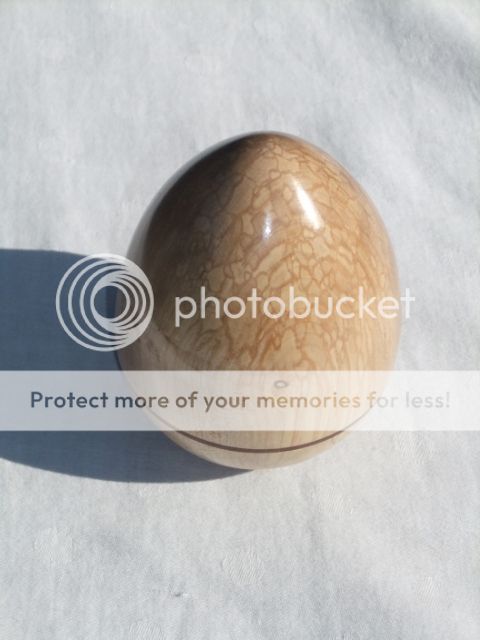

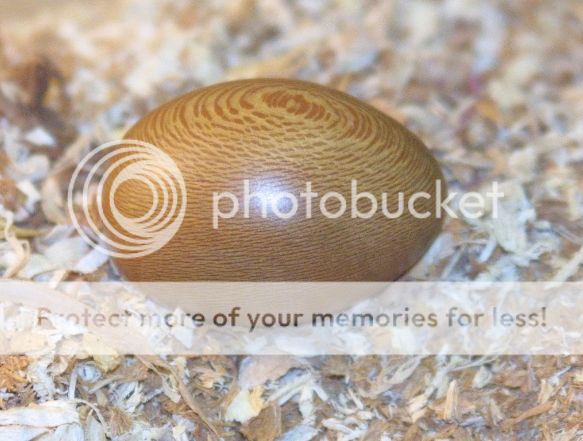

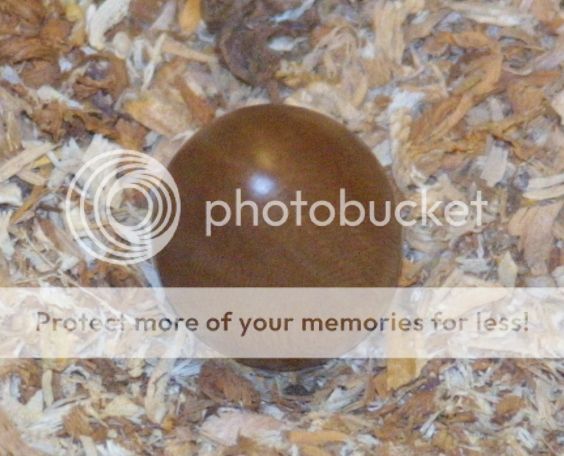

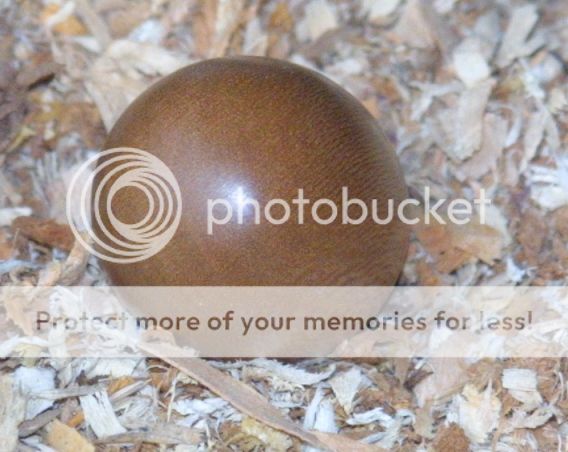

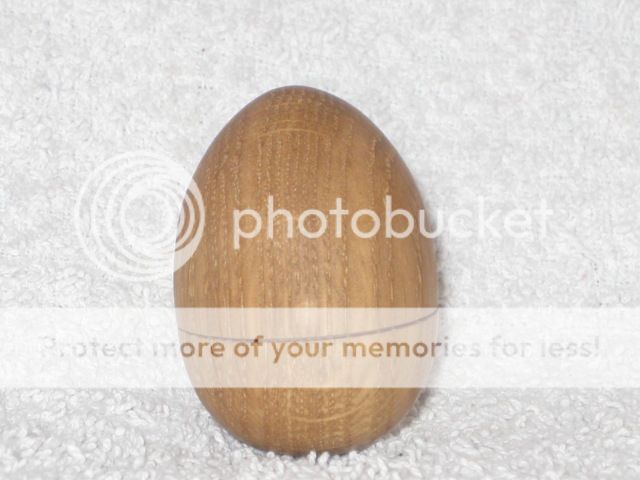

Challenge Requirements: An Easter Egg (singular, no clutches!)

This month’s rules are:-

The Challenge is open to anyone and everyone

Your entry must be new and made specifically for the Challenge

Entries must be made of wood and turned on a lathe using woodturning tools.

There are no maximum or minimum size restrictions, but entries must be oviform.

Segmented turning, decoration, colouring, piercing, hollowing, pyrography and texturing are all allowed, but the principal requirement is for your entry to be egg-shaped (obviously!) and to show off your turning skills.

Please post 3 images of your work along with a brief note about how you made it, what tools and finishes you used, what wood you used and the egg’s dimensions etc.

1 showing a general view

1 showing a top view

1 showing a bottom view

Image size - please use image size 640 x 480 0.3 mp, as in previous challenges

Please upload your pictures and description between 10pm on the 26th April and 10pm on the 28th April.

Please also send me a PM giving me your own opinions of 1st, 2nd and 3rd places amongst the entries (other than your own) between 10pm on 28th April and 10pm on 30th April (for me to compile the entrants’ scoring).

ROUNDUP

Challenge Requirements: An Easter Egg (singular, no clutches!)

This month’s rules are:-

The Challenge is open to anyone and everyone

Your entry must be new and made specifically for the Challenge

Entries must be made of wood and turned on a lathe using woodturning tools.

There are no maximum or minimum size restrictions, but entries must be oviform.

Segmented turning, decoration, colouring, piercing, hollowing, pyrography and texturing are all allowed, but the principal requirement is for your entry to be egg-shaped (obviously!) and to show off your turning skills.

Please post 3 images of your work along with a brief note about how you made it, what tools and finishes you used, what wood you used and the egg’s dimensions etc.

1 showing a general view

1 showing a top view

1 showing a bottom view

Image size - please use image size 640 x 480 0.3 mp, as in previous challenges

Please upload your pictures and description between 10pm on the 26th April and 10pm on the 28th April.

Please also send me a PM giving me your own opinions of 1st, 2nd and 3rd places amongst the entries (other than your own) between 10pm on 28th April and 10pm on 30th April (for me to compile the entrants’ scoring).

ROUNDUP