chippy1970

Established Member

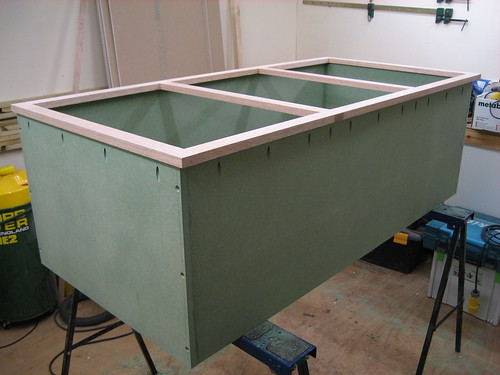

I am about to build some framed vanity units for a client with shaker style doors and corner bead detail around the frames.

I have the doors off to a tee as I have made loads but I would appreciate any advice or links to websites about making framed kitchen units.

I have a corner bead router cutter for the frames and was thinking of fixing the face frames with a Kreg jig maybe the standard £50 one, anyone know much about the Kreg ones ?

I have the doors off to a tee as I have made loads but I would appreciate any advice or links to websites about making framed kitchen units.

I have a corner bead router cutter for the frames and was thinking of fixing the face frames with a Kreg jig maybe the standard £50 one, anyone know much about the Kreg ones ?