DomD

Established Member

- Joined

- 10 Feb 2019

- Messages

- 171

- Reaction score

- 8

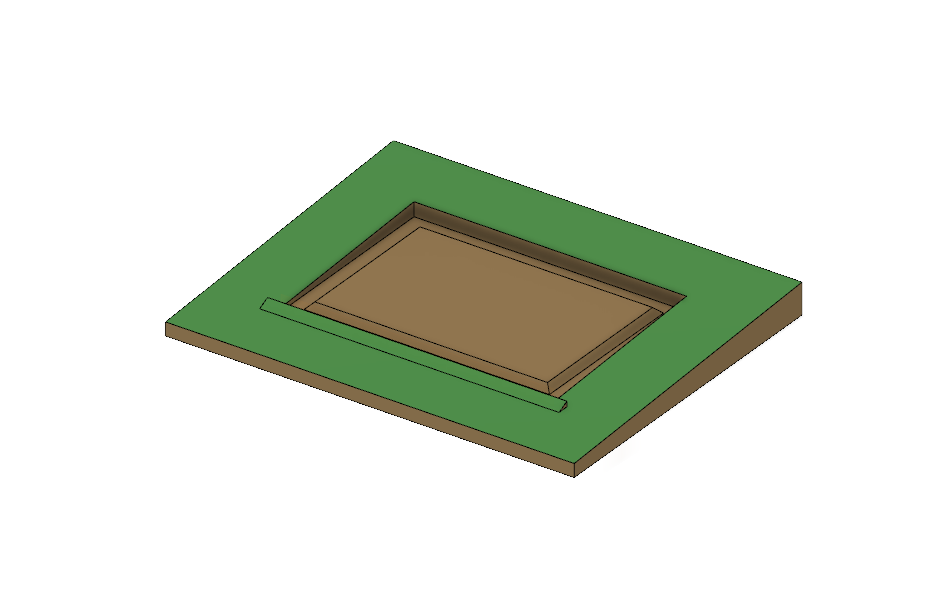

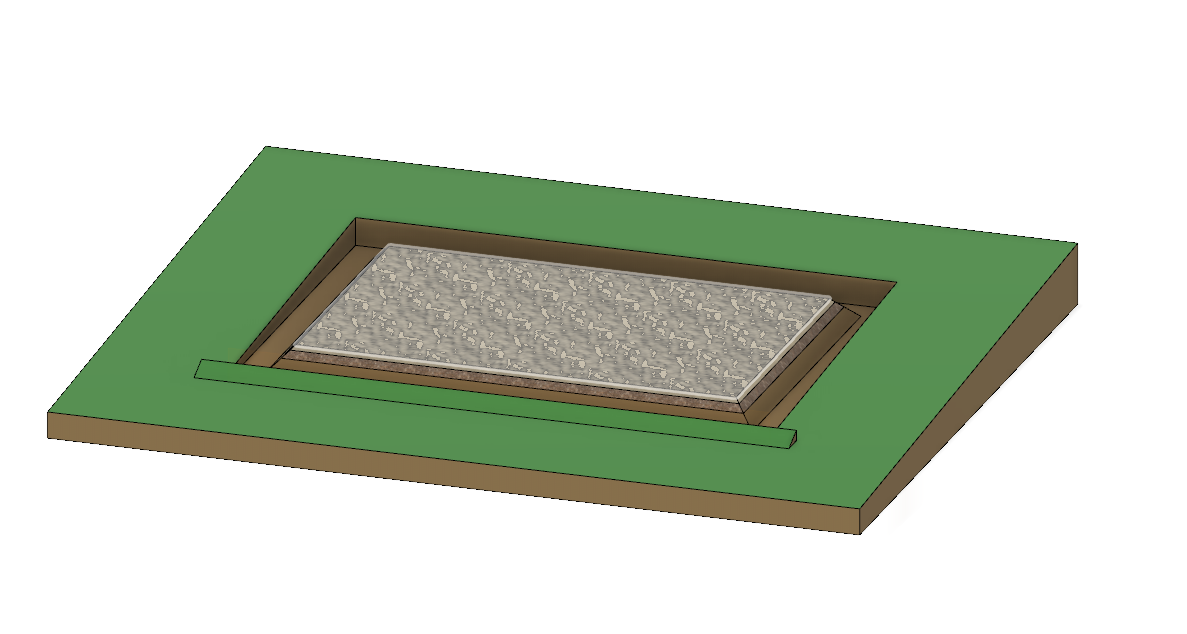

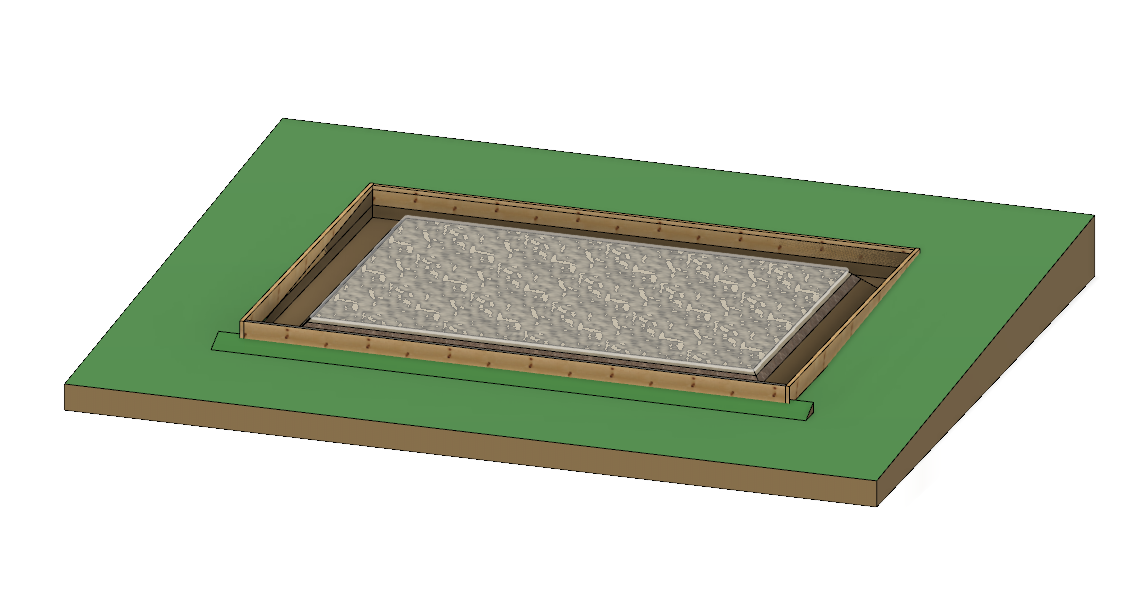

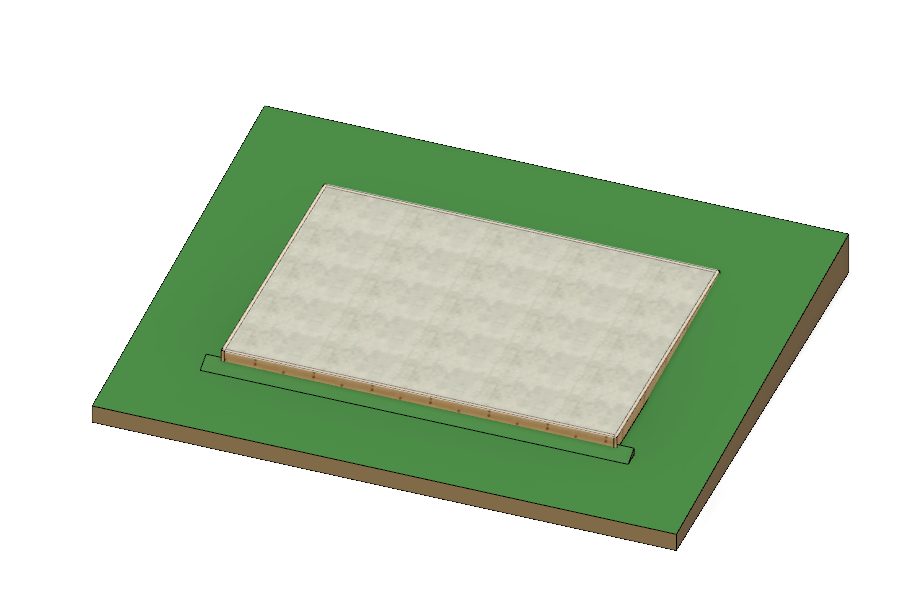

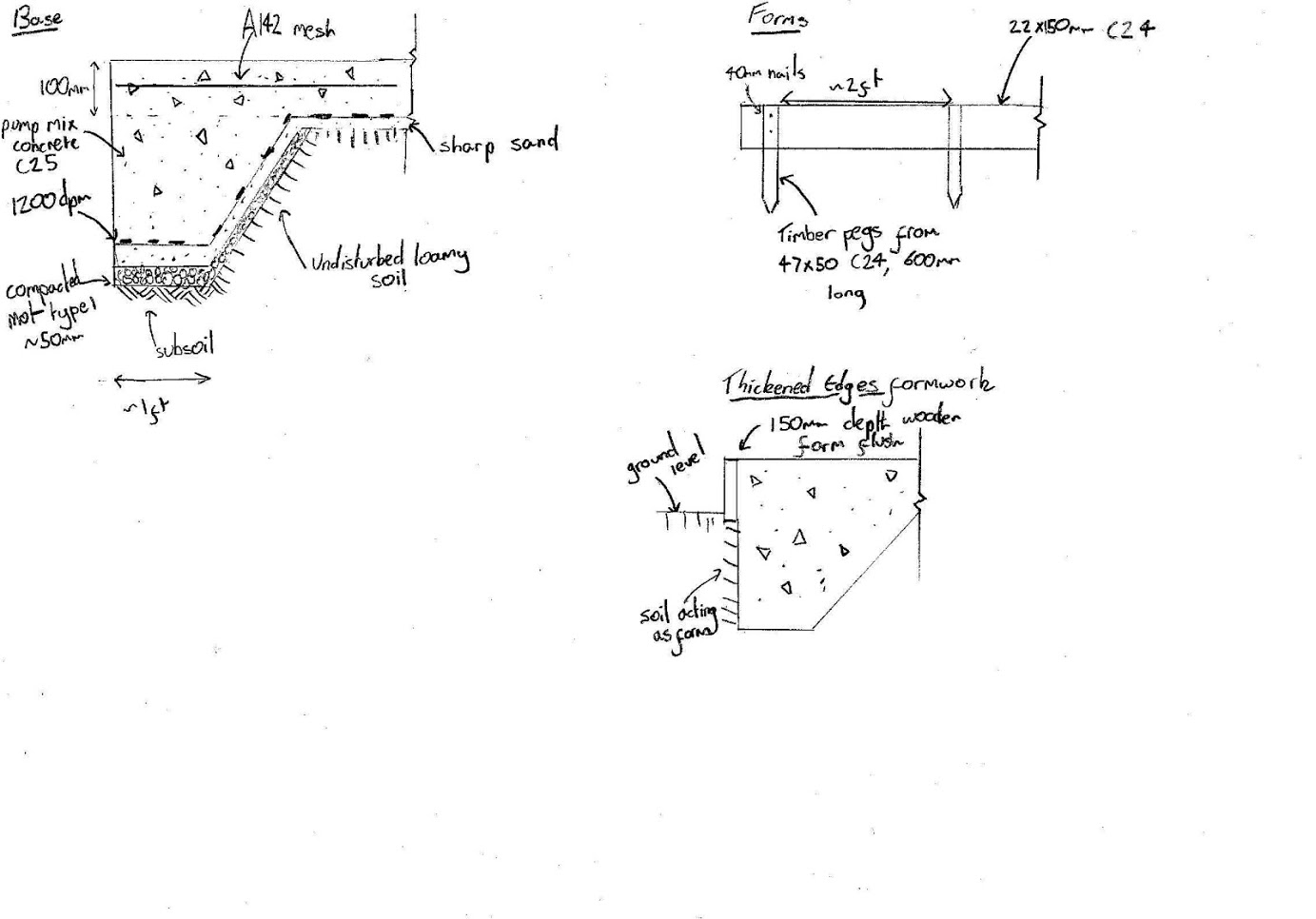

For the thickened edges I plan to have 4 16mm diameter bars running down each similar to shown below (but only one covering of mesh).

I'm guessing the link members only need to be regular enough to hold the other bars in place.

At the corners should the steel be bent round or is it fine to just cut it to length and tie to the other bars at right angles.

Also, would reducing the slab thickness to 100mm have much of an impact on strength?

Thanks

I'm guessing the link members only need to be regular enough to hold the other bars in place.

At the corners should the steel be bent round or is it fine to just cut it to length and tie to the other bars at right angles.

Also, would reducing the slab thickness to 100mm have much of an impact on strength?

Thanks