Hello all,

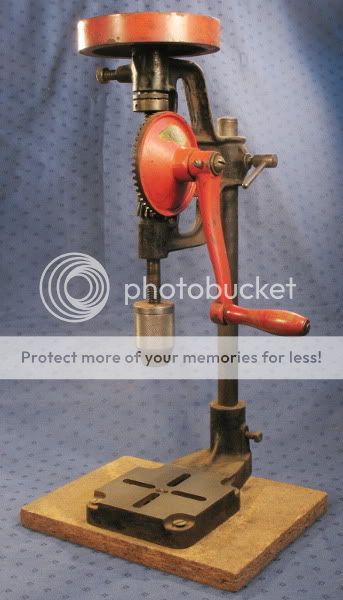

I've just bought a small hand cranked pillar drill:

When I turn the handle, the chuck spins as you would expect, but it doesn't go up and down, so how do you use it to drill a hole?

Or is there a setting I've missed?

It's only marked as "British Made".

I've just bought a small hand cranked pillar drill:

When I turn the handle, the chuck spins as you would expect, but it doesn't go up and down, so how do you use it to drill a hole?

Or is there a setting I've missed?

It's only marked as "British Made".