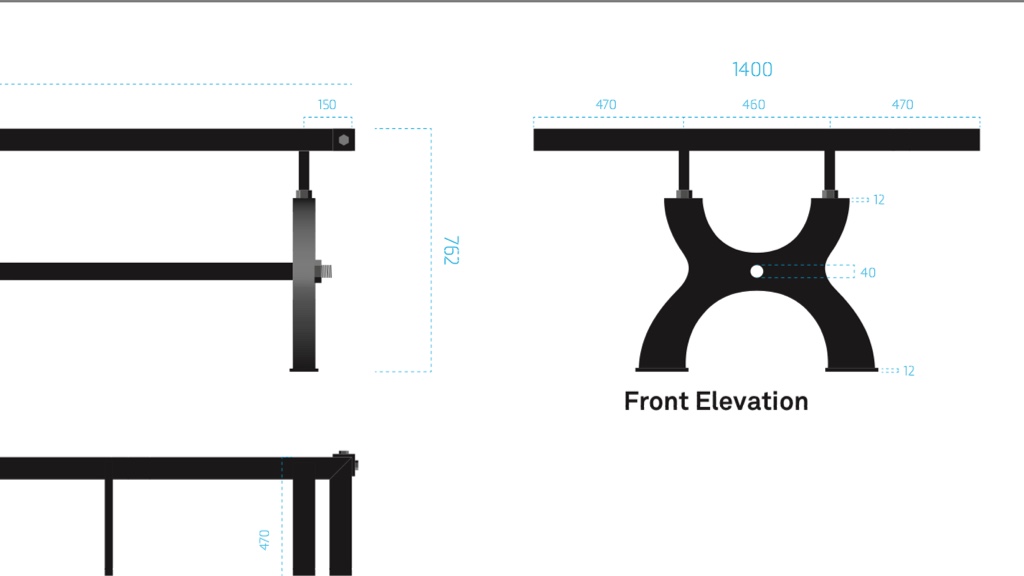

Only steel so far, but the woodwork will start shortly. The idea was to have a height adjustable table, so the threaded bar can raise the frame from the end blocks. The ends were laser cut from 8mm black steel, this shape was given depth by folding and welding steel to it.

Centre connecting pipe is scaffold. End nuts are scaffold height adjustment jacks.

Lots of square profile steel to hold the wood

Now the hard bit - jointing 4 planks of 2" x 14" x 10' mahogany so that the join is near invisible. Moving the planks is tough so some planning is ahead.

The 2" wood will sit inside the frame for 1" depth, so that 1" will sit proud. A 3/4" rabbet will protrude to sit flush with the steel frame, and hide the expansion gap.

I found a Sedgwick CP on eBay to help me get accurate edges for gluing, and to thickness. I might dowel or biscuit the four planks together, to keep everything in place as I glue up. Final clean up will be with hand planes. Any advice well appreciated

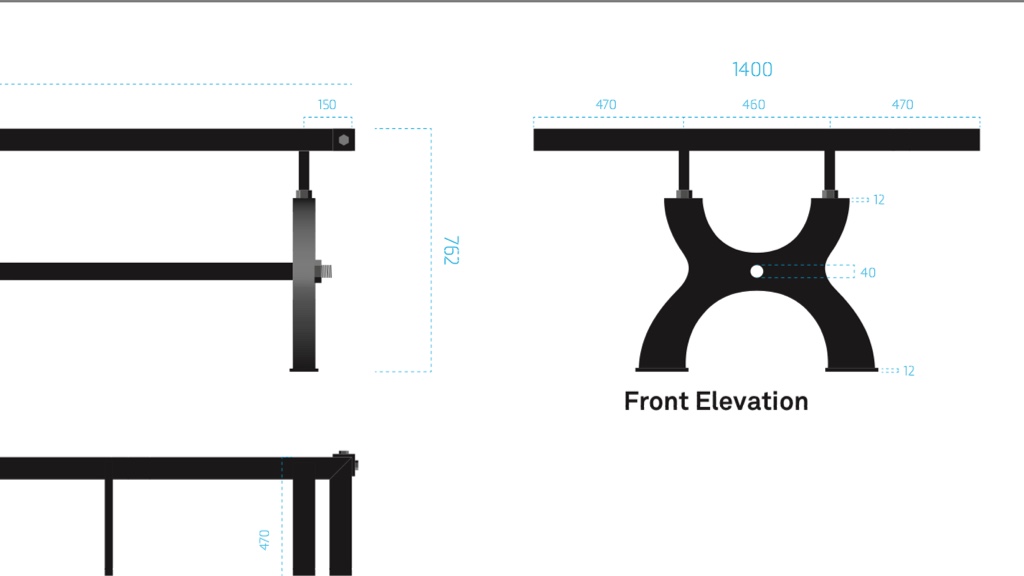

Centre connecting pipe is scaffold. End nuts are scaffold height adjustment jacks.

Lots of square profile steel to hold the wood

Now the hard bit - jointing 4 planks of 2" x 14" x 10' mahogany so that the join is near invisible. Moving the planks is tough so some planning is ahead.

The 2" wood will sit inside the frame for 1" depth, so that 1" will sit proud. A 3/4" rabbet will protrude to sit flush with the steel frame, and hide the expansion gap.

I found a Sedgwick CP on eBay to help me get accurate edges for gluing, and to thickness. I might dowel or biscuit the four planks together, to keep everything in place as I glue up. Final clean up will be with hand planes. Any advice well appreciated