Well, I say blame, it's more of a polite thankyou. And also 'Toolsntat' Andy, who sent me a tip-off that a rather interesting item was on ebay, collection only, in Bristol.

So I've done the deed and bought it. I've also brought it home in semi-portable bits. Good grief but it's solid!

I'm talking about a Barnes 4 1/2 treadle driven metalworking lathe.

It's the model Roy Underhill featured in this programme - http://video.unctv.org/video/2296983856 which is little more than a half hour advert for the thing!

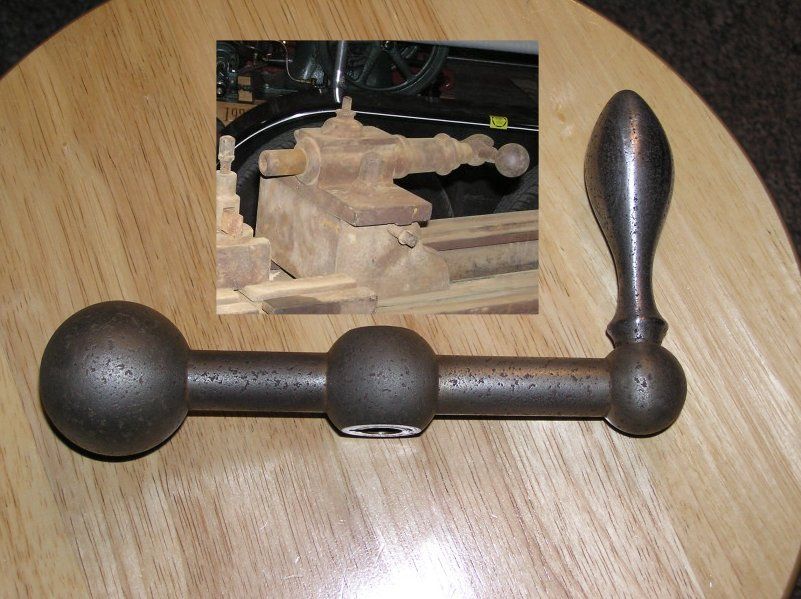

This is the ebay listing photo showing it assembled:

And here are some close-ups of it in bits in my workshop:

As far as I can see there are no important bits missing and there is just one handle broken. Most of the bits move and it looks as if it was well greased before being left unloved in a shed for a while. It comes with a three jaw chuck, a four jaw and a faceplate. It has a set of change gears to power the toolrest along to do thread cutting. Yahoo!!

It will be "some time" before I post any video of it whirring away happily and I expect I'll be back with lots of questions, especially to the serial restorers of lumps of old cast iron.

For starters, what's the best sort of degreaser to use these days?

And what bits turn against what other bits to get the chuck open and removed?

So I've done the deed and bought it. I've also brought it home in semi-portable bits. Good grief but it's solid!

I'm talking about a Barnes 4 1/2 treadle driven metalworking lathe.

It's the model Roy Underhill featured in this programme - http://video.unctv.org/video/2296983856 which is little more than a half hour advert for the thing!

This is the ebay listing photo showing it assembled:

And here are some close-ups of it in bits in my workshop:

As far as I can see there are no important bits missing and there is just one handle broken. Most of the bits move and it looks as if it was well greased before being left unloved in a shed for a while. It comes with a three jaw chuck, a four jaw and a faceplate. It has a set of change gears to power the toolrest along to do thread cutting. Yahoo!!

It will be "some time" before I post any video of it whirring away happily and I expect I'll be back with lots of questions, especially to the serial restorers of lumps of old cast iron.

For starters, what's the best sort of degreaser to use these days?

And what bits turn against what other bits to get the chuck open and removed?