Scouse

Established Member

I have had an eye out for a lathe for a while; to be honest it has been a bit of a lazy search, I don't know the first thing about them so I was just watching the occasional potential victim on ebay which wasn't too far away, wasn't too much money and was old enough to make it interesting, or more difficult depending on the point of view.

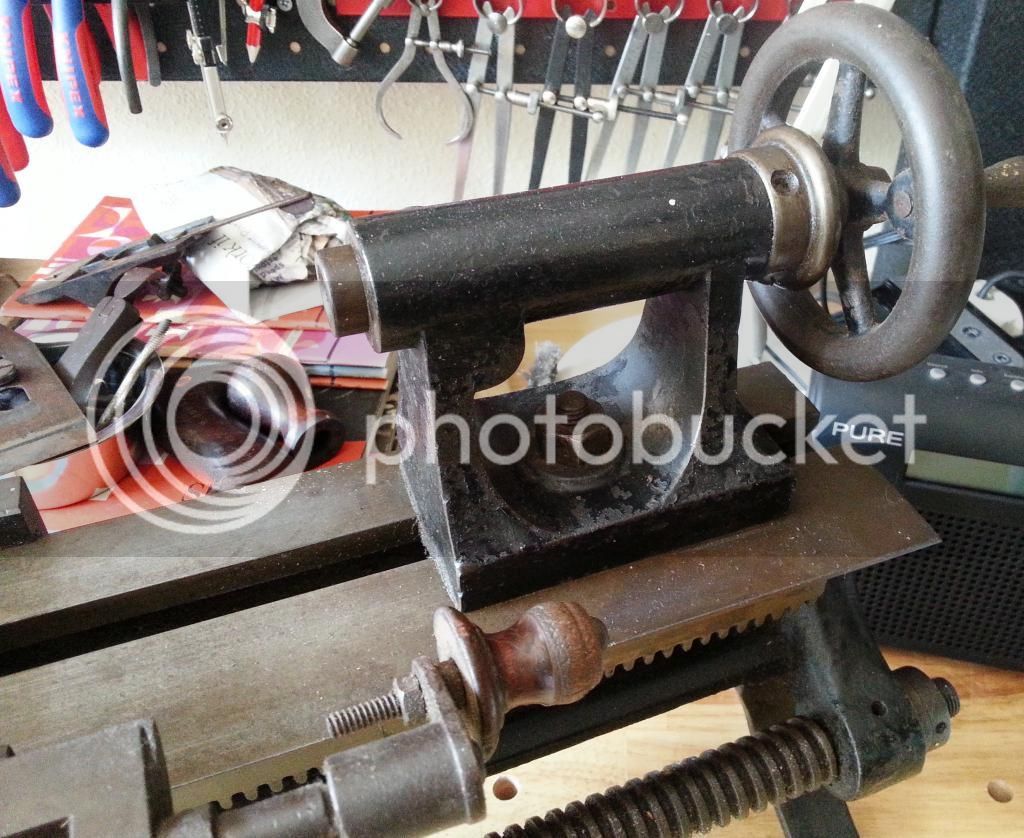

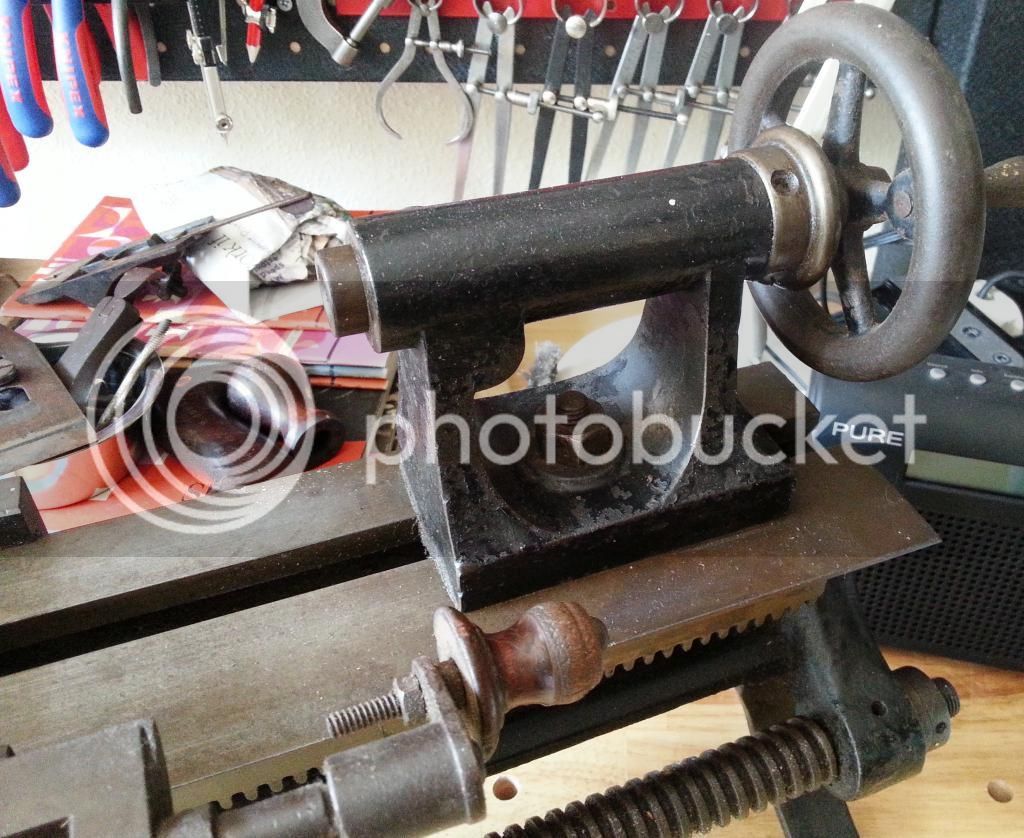

So it was on Saturday afternoon, while taking a leisurely stroll into the village, my partner noted a small ad in a shop window. It must be said that she is a ninja when it comes to spotting rusty old stuff which I invariably miss, as was the case here as I walked past the shop oblivious. It had already been reduced once and the paper was yellowing so I wasn't confident, but a quick phone call and a 500 yard drive and I was in a garage next to a gorgeous restored Ford Pop looking at this.

Britannia of Colchester lathe. The owner was a retired chemical engineer who no longer used it and was more interested in it going to a good home than its financial value.

He informed me that he had been told that it was an 1898 model 13, which I guess fits with the info on Tony's site (lathes.co.uk). I have to say that on quick inspection and without getting misty eyed, in common with most old engineering, it is needlessly beautiful, even down to a tiny bead around the edge of the original wooden handles.

Anyway it came with a boxfull of stuff, which is where you lot come in, because I don't know what is for the lathe and what is just general unrelated stuff. I do know these are changewheels for the screw cutting (might need a manual to figure them out...)

but as to this lot

Some bits I know, spare jaws, the woodworking rest and its attachments, but these?

Two of the three above J and S things are cranked, one is straight (doesn't show very well in the picture)

(the little bowl in the last picture is made of brass)

It came with the original base which had sadly lost its treadle mechanism in the past, but after removing a piece of hardboard revealed the original hardwood bench top complete with holes for the treadle belt

As a consolation the treadle has been replaced by a massive and gorgeous 1930's Crompton Parkinson repulsion start induction motor, completely silent and no bearing play what-so-ever

The final bits, the fitted four jaw chuck which needs each jaw to be adjusted independently, a faceplate, apparently, whatever that is and a Taylor self centering chuck which weighs a ton and are quite good apparently.

So a good clean is in progress as we speak, and although the motor runs nicely I might have it checked for safety since it has had a new wire fitted into the original bakelite block; an NVR switch might be a good idea too.

As an interesting post script, I bought a new wallet last week, bear with me; it only has one note section as opposed to my old one within which I used to separate business and personal money. I had 20 or thirty quid in it when I went to the bank for the lathe money and when I paid, I just absent-mindedly took the notes out of the wallet and gave them to the Steve the seller. When I got home I realised I had inadvertantly paid over the asking price for the lathe. I didn't really mind because I thought it was probably worth it, just felt a bit daft. A couple of hours later a knock on the door revealed Steve, who had driven up and down the mile and a bit length of my road looking for my car to return the money. I split it with him and after some reluctance said he would give it to Alzhiemers Research, but talk about having your faith restored! Genuinely decent bloke.

So what are all the bits? How does it all work? And what should I make first? All help appreciated!

So it was on Saturday afternoon, while taking a leisurely stroll into the village, my partner noted a small ad in a shop window. It must be said that she is a ninja when it comes to spotting rusty old stuff which I invariably miss, as was the case here as I walked past the shop oblivious. It had already been reduced once and the paper was yellowing so I wasn't confident, but a quick phone call and a 500 yard drive and I was in a garage next to a gorgeous restored Ford Pop looking at this.

Britannia of Colchester lathe. The owner was a retired chemical engineer who no longer used it and was more interested in it going to a good home than its financial value.

He informed me that he had been told that it was an 1898 model 13, which I guess fits with the info on Tony's site (lathes.co.uk). I have to say that on quick inspection and without getting misty eyed, in common with most old engineering, it is needlessly beautiful, even down to a tiny bead around the edge of the original wooden handles.

Anyway it came with a boxfull of stuff, which is where you lot come in, because I don't know what is for the lathe and what is just general unrelated stuff. I do know these are changewheels for the screw cutting (might need a manual to figure them out...)

but as to this lot

Some bits I know, spare jaws, the woodworking rest and its attachments, but these?

Two of the three above J and S things are cranked, one is straight (doesn't show very well in the picture)

(the little bowl in the last picture is made of brass)

It came with the original base which had sadly lost its treadle mechanism in the past, but after removing a piece of hardboard revealed the original hardwood bench top complete with holes for the treadle belt

As a consolation the treadle has been replaced by a massive and gorgeous 1930's Crompton Parkinson repulsion start induction motor, completely silent and no bearing play what-so-ever

The final bits, the fitted four jaw chuck which needs each jaw to be adjusted independently, a faceplate, apparently, whatever that is and a Taylor self centering chuck which weighs a ton and are quite good apparently.

So a good clean is in progress as we speak, and although the motor runs nicely I might have it checked for safety since it has had a new wire fitted into the original bakelite block; an NVR switch might be a good idea too.

As an interesting post script, I bought a new wallet last week, bear with me; it only has one note section as opposed to my old one within which I used to separate business and personal money. I had 20 or thirty quid in it when I went to the bank for the lathe money and when I paid, I just absent-mindedly took the notes out of the wallet and gave them to the Steve the seller. When I got home I realised I had inadvertantly paid over the asking price for the lathe. I didn't really mind because I thought it was probably worth it, just felt a bit daft. A couple of hours later a knock on the door revealed Steve, who had driven up and down the mile and a bit length of my road looking for my car to return the money. I split it with him and after some reluctance said he would give it to Alzhiemers Research, but talk about having your faith restored! Genuinely decent bloke.

So what are all the bits? How does it all work? And what should I make first? All help appreciated!