I know how they work but that is all... and now i'm currently trying to see if i can get a replacement, if anyone can help.

I've contacted the store seller and their recommendations with no luck so thinking it's not possible.

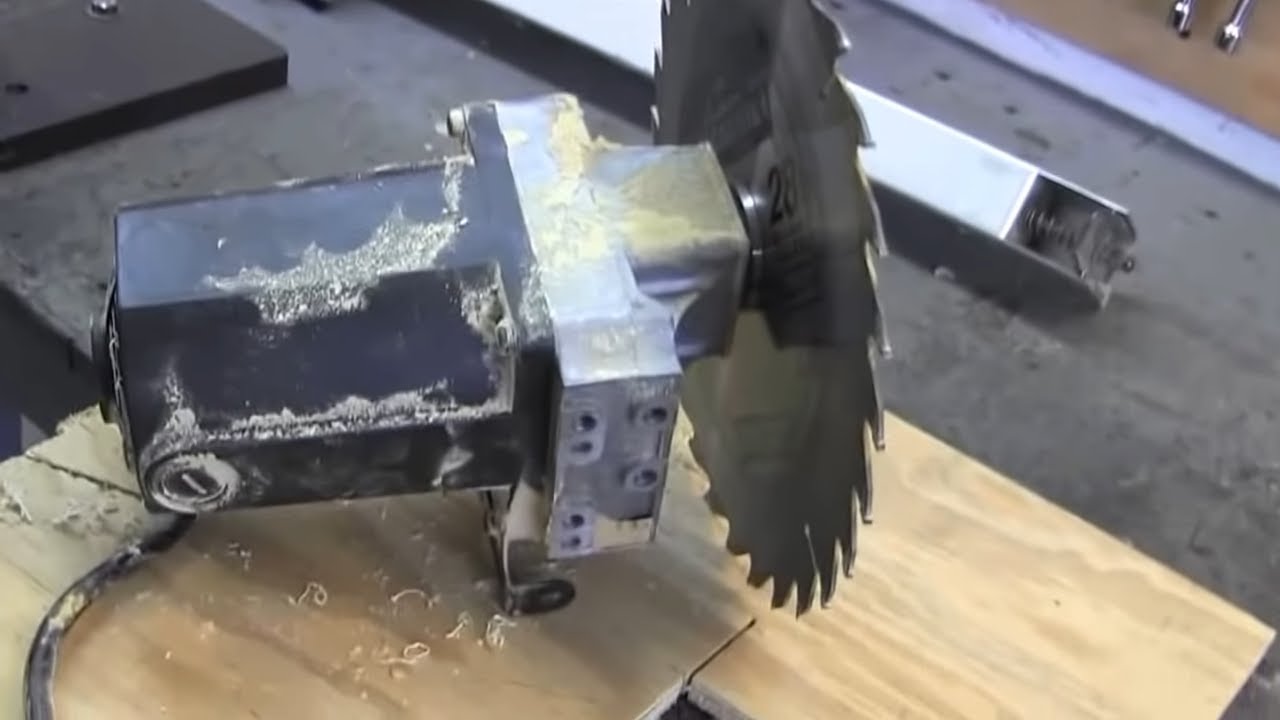

It's from this cheap planer sold at screwfix... and it was my own fault the motor melted , i stupidly blocked the vent on the bottom of it and had it running for quite some time that it built up too much heat and melted.

Anyway...

The important stuff is...

230-240v 1500w

no load speed 9000/min

I'll get a pic up of the motor shortly

I've contacted the store seller and their recommendations with no luck so thinking it's not possible.

It's from this cheap planer sold at screwfix... and it was my own fault the motor melted , i stupidly blocked the vent on the bottom of it and had it running for quite some time that it built up too much heat and melted.

Anyway...

The important stuff is...

230-240v 1500w

no load speed 9000/min

I'll get a pic up of the motor shortly