carlb40

Established Member

Started mine today. A little short on cash as i am between jobs at the mo. So decided to go the reclaimed timber route.

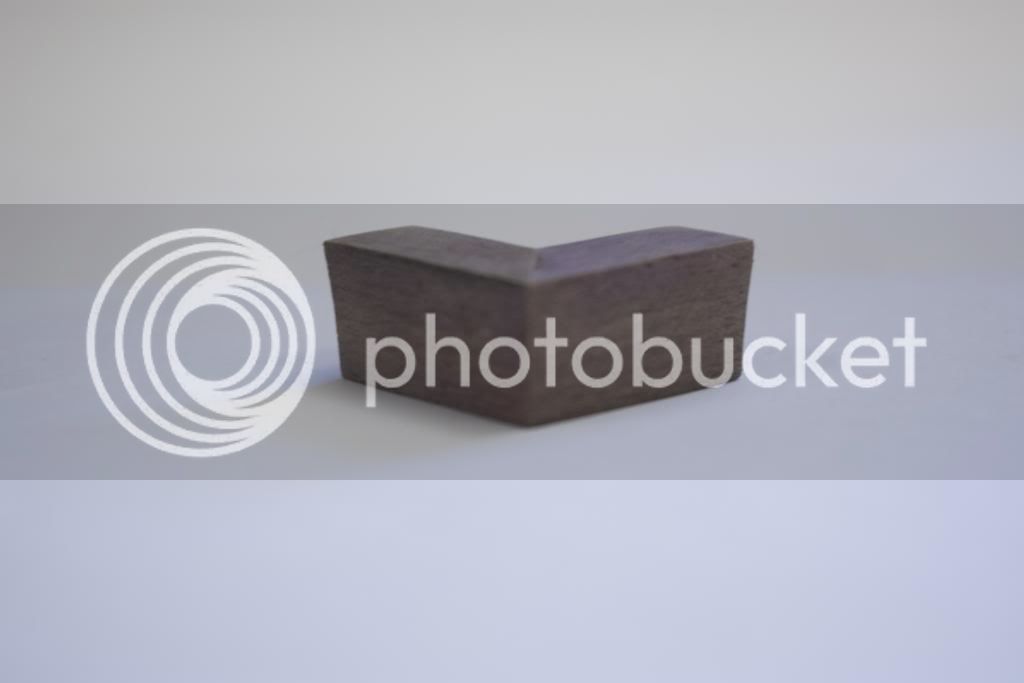

I have had these shelves 8+ yrs now just sitting around. Almost did some with them last year and started to scrape the paint off. Revealing IMO a hideous veneer on it.

It was about 1-1.5mm thick

After trying boiling water etc to remove the veneer and not working. I bunged both pieces through my thicknesser, carefully taking about .2mm off at a time.

The resulting timber i think looks much nicer

As you can see i have some stringing already done for me LOL

Not sure what type of timber it is? If anyone knows please step forward

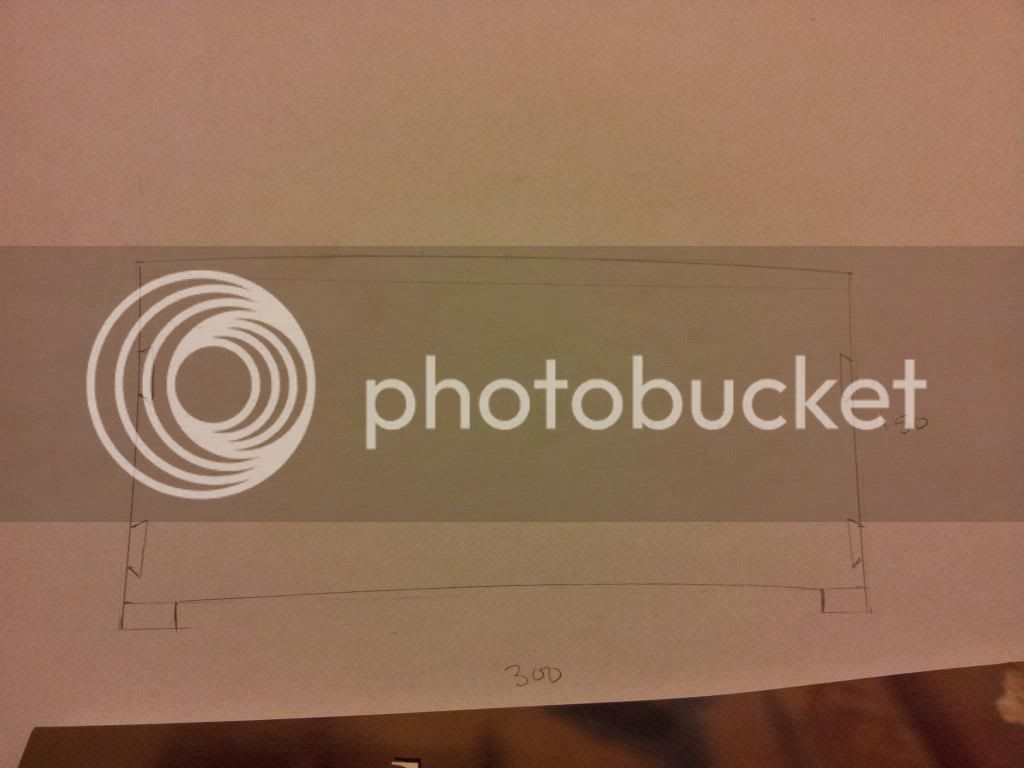

Don't normally do 'plans' . Well i do, but they normally stay in my head :lol:

Now this will be a few firsts for me, using a plan and as usual for be going overboard on a project :mrgreen:

After searching for various designs and not being taken with any - either the oriental/ japanese or mission style boxes.

I gave up and went for a bath. Then while lying there i designed this in my head

The curve on the side will be replicated on the front/ rear. The dovetails will be just reinforcements for the mitres, in a contrasting timber and possibly the same for the feet.

Probably been done before and by wayyyy better peeps than me.

So stay tuned for my epic failure #-o

I have had these shelves 8+ yrs now just sitting around. Almost did some with them last year and started to scrape the paint off. Revealing IMO a hideous veneer on it.

It was about 1-1.5mm thick

After trying boiling water etc to remove the veneer and not working. I bunged both pieces through my thicknesser, carefully taking about .2mm off at a time.

The resulting timber i think looks much nicer

As you can see i have some stringing already done for me LOL

Not sure what type of timber it is? If anyone knows please step forward

Don't normally do 'plans' . Well i do, but they normally stay in my head :lol:

Now this will be a few firsts for me, using a plan and as usual for be going overboard on a project :mrgreen:

After searching for various designs and not being taken with any - either the oriental/ japanese or mission style boxes.

I gave up and went for a bath. Then while lying there i designed this in my head

The curve on the side will be replicated on the front/ rear. The dovetails will be just reinforcements for the mitres, in a contrasting timber and possibly the same for the feet.

Probably been done before and by wayyyy better peeps than me.

So stay tuned for my epic failure #-o