You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Box Mitre

- Thread starter Richard T

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Richard T

Established Member

Yes Jim, a cheap, narrow car boot Marples I think it is but I need something wider too - an excuse to buy chisels from car boot sales again as square ended scraper fodder. Hooray!

Thanks Toby. You have great faith ....

Rxh, no adjuster. It has the bridge for a wedge. More fun with Yew.

I put it together this afternoon. Nearly forgot to do something that I have only just noticed on Bill's CD - to take some off the inside of the tenons

in case peining squishes them sideways into the mouth area.

Other things to do were to open the mouth a little and to clean up the ends of the sole that will protrude past the body at either end and will be difficult to do any major scratch removal with it together. Some work is inevitable but here's hoping for as little as poss. in those corners.

And of course, file the compounds.

I did it up on the big anvil. It's so much easier to pein than a smoother or a panel ... it's flat all over, so no need for anything other than the anvil. Here is my cross pein punch spreading from the middle to the edges and filling in the compound corners:

Made sure the corners were filled and did the sides up.

Then Dreadnought work taking the waste off

and switching to a cross cut file as I start to blend in with the side - drawing the file. Just the one stray hammer mark that did disappear eventually.

More soon - the ugly part is nearly over.

Thanks Toby. You have great faith ....

Rxh, no adjuster. It has the bridge for a wedge. More fun with Yew.

I put it together this afternoon. Nearly forgot to do something that I have only just noticed on Bill's CD - to take some off the inside of the tenons

in case peining squishes them sideways into the mouth area.

Other things to do were to open the mouth a little and to clean up the ends of the sole that will protrude past the body at either end and will be difficult to do any major scratch removal with it together. Some work is inevitable but here's hoping for as little as poss. in those corners.

And of course, file the compounds.

I did it up on the big anvil. It's so much easier to pein than a smoother or a panel ... it's flat all over, so no need for anything other than the anvil. Here is my cross pein punch spreading from the middle to the edges and filling in the compound corners:

Made sure the corners were filled and did the sides up.

Then Dreadnought work taking the waste off

and switching to a cross cut file as I start to blend in with the side - drawing the file. Just the one stray hammer mark that did disappear eventually.

More soon - the ugly part is nearly over.

jimi43

Established Member

I love the peining start with the rounded punch...must remember than one next time I do metal dovetails.

Coming on fine Richard!

Jimi

Coming on fine Richard!

Jimi

Richard T

Established Member

Mr. P(unch) - the mouth gap is made .... it's a bevel up mitre plane. Is that what you mean? (very narrow)

Blimey just had a look at a few antique soles on jimbodetools.com and they do indeed have very, very tight mouths.

Bevel up + v.low angle iron = Extremely tight mouth.

Can you even get a match in that mouth ?

Thank you the penny has dropped.

Bevel up + v.low angle iron = Extremely tight mouth.

Can you even get a match in that mouth ?

Thank you the penny has dropped.

Richard T

Established Member

Thanks Andy - I'm sure Bill will find plenty wrong with it. He told me I'd cut the pins the wrong way round before I told him which side was which ... (hammer) . More on that off cut in a bit.

I draw filed the sole today - trying to get it as flat as possible before starting to lap.

When there is a long way to go, I start to draw with a Dreadnought.

Why waste time with any other tool like a piddling little bench file or a milling machine? Only half - joking there but there is a downside to all draw filing. You can never remove as much stuff at the ends as you can in the middle. So anything short will always tend toward concavity; like oil/water stones always do with use. Fortunately the Dreadnought provides its own straight edge for checking.

To counter this I cross file the ends occasionally and then draw out the marks.

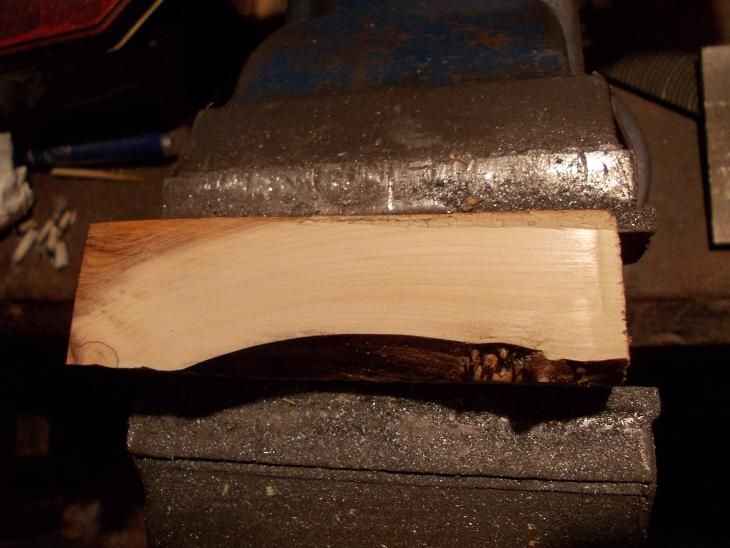

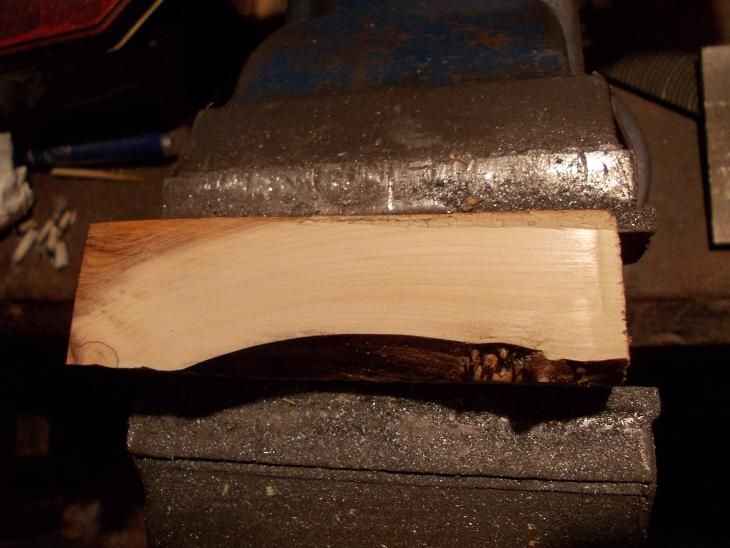

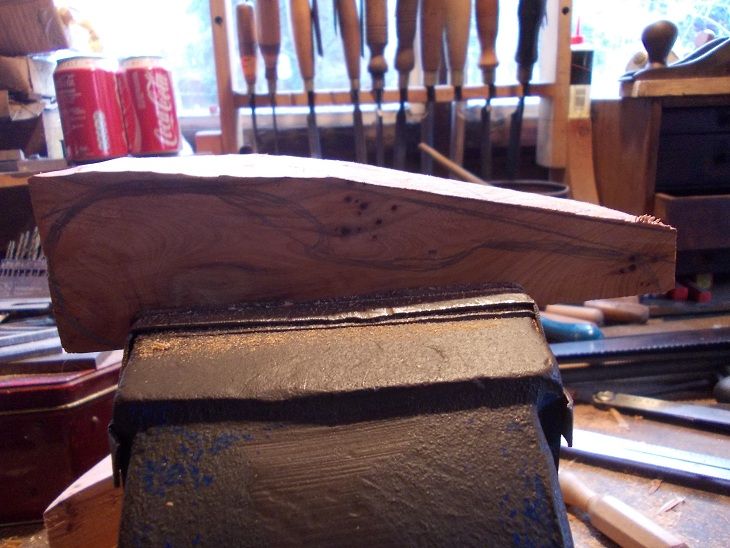

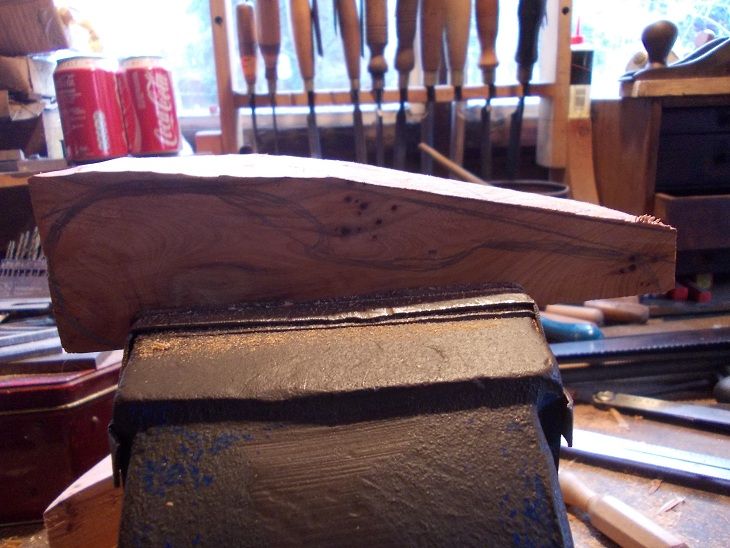

Back to that off cut and taming Yew in general - I had a go at planing the other edge:

I know it's mostly sap wood but it's still very hard and there is a knot at the end. It's all down to the choice of plane and the one I used did it perfectly .... even though it has no infill or wedge yet and I was just holding the iron in place with my fingertips...

I like mitres. You couldn't do that with a half made BD. The definition of a mitre plane could be: "Thingy to hold your paring chisel properly"

Just for Mr. P - here is the blade at full extension. Too far out of course as to have it this far forward closes the gap.

I'm loving making this. I just hope I can get the woodwork right.

I draw filed the sole today - trying to get it as flat as possible before starting to lap.

When there is a long way to go, I start to draw with a Dreadnought.

Why waste time with any other tool like a piddling little bench file or a milling machine? Only half - joking there but there is a downside to all draw filing. You can never remove as much stuff at the ends as you can in the middle. So anything short will always tend toward concavity; like oil/water stones always do with use. Fortunately the Dreadnought provides its own straight edge for checking.

To counter this I cross file the ends occasionally and then draw out the marks.

Back to that off cut and taming Yew in general - I had a go at planing the other edge:

I know it's mostly sap wood but it's still very hard and there is a knot at the end. It's all down to the choice of plane and the one I used did it perfectly .... even though it has no infill or wedge yet and I was just holding the iron in place with my fingertips...

I like mitres. You couldn't do that with a half made BD. The definition of a mitre plane could be: "Thingy to hold your paring chisel properly"

Just for Mr. P - here is the blade at full extension. Too far out of course as to have it this far forward closes the gap.

I'm loving making this. I just hope I can get the woodwork right.

Paul Chapman

Established Member

Great work, Richard 8)

Cheers :wink:

Paul

Cheers :wink:

Paul

jimi43

Established Member

Racers":2bz9vs0e said:Hi Richard

Have you tried the Dreadnaught on the Yew?

Its coming along very well.

Pete

Now that's a good idea Pete!!

Jimi

condeesteso

Established Member

Looking very impressive indeed. I can't tell the scale of this plane (sorry if I missed some dimensions) but overall length and cutter width?

Also what is the bed angle, I notice bridge at +7 so I assume wedge will be 7 degrees - is the bed around 10-12?

The comment about paring chisel holder is probably more significant than first appears - I've previously found that under 25 degrees edge on those is quite risky (esp. on proper hard woods). Just interested in final target cutting angle? And I'm assuming this will be bevel-up, no cap iron?

Sorry, questions...

I think the yew is a great choice, and pleased to see you now mark your name on these planes. For a bit of heritage why not stamp the back of iron and top of bed with matching numbers (a bit Spiers-like) and maybe hide a date somewhere too (just an 02-14 say). Give the collectors more to worry about in decades to come - just make it as hard as possible for them :lol:

Regarding the sole dovetails, aren't they effectively compound dovetails anyway, once peined - i mean they flare in both directions and the peining fills it all out?

Oh, and let us know the weight when it's all done please. That'll do for now :wink:

Fine work indeed =D>

Also what is the bed angle, I notice bridge at +7 so I assume wedge will be 7 degrees - is the bed around 10-12?

The comment about paring chisel holder is probably more significant than first appears - I've previously found that under 25 degrees edge on those is quite risky (esp. on proper hard woods). Just interested in final target cutting angle? And I'm assuming this will be bevel-up, no cap iron?

Sorry, questions...

I think the yew is a great choice, and pleased to see you now mark your name on these planes. For a bit of heritage why not stamp the back of iron and top of bed with matching numbers (a bit Spiers-like) and maybe hide a date somewhere too (just an 02-14 say). Give the collectors more to worry about in decades to come - just make it as hard as possible for them :lol:

Regarding the sole dovetails, aren't they effectively compound dovetails anyway, once peined - i mean they flare in both directions and the peining fills it all out?

Oh, and let us know the weight when it's all done please. That'll do for now :wink:

Fine work indeed =D>

Richard T

Established Member

Apologies for loss of service - computer has blown a gasket. This from phone.

Bed angle 20 degrees, iron width 2", NSWBRASAP.

Sent from my ST26i using Tapatalk

Bed angle 20 degrees, iron width 2", NSWBRASAP.

Sent from my ST26i using Tapatalk

jimi43

Established Member

What's an ST26i Richard?

Is it an old Amiga PC!!! :mrgreen:

Awaiting NORMAL SERVICE....(boy you had me going there for a bit! )

)

If the PC not restored will it be FITS? :wink:

Jim

Is it an old Amiga PC!!! :mrgreen:

Awaiting NORMAL SERVICE....(boy you had me going there for a bit!

If the PC not restored will it be FITS? :wink:

Jim

Richard T

Established Member

Well that was a bit of a nightmare ... two weeks computerless and no way to check the styles of other plane wedges. I've had to resort to reading books. Now we have a shiny new pooter and I am only just starting to work out how to find the photos that disappear from the camera and gurgle out of reach into unreachable chasms of Windows7.

Anyway, I'll try some update photos.

I made the wedge much too big just in case .... squinting at small photos in last year's David Stanley catalogue ... but it is now a better size since I have had the chance to look at Bill's work again.

The iron that is in it is just a slotted parallel upside down - I need to get some more tool steel and make a proper, long, snecked mitre iron.

Anyway, I'll try some update photos.

I made the wedge much too big just in case .... squinting at small photos in last year's David Stanley catalogue ... but it is now a better size since I have had the chance to look at Bill's work again.

The iron that is in it is just a slotted parallel upside down - I need to get some more tool steel and make a proper, long, snecked mitre iron.

jimi43

Established Member

Oh dear Richard! :shock: :shock: :shock:

That is so GORGEOUS!!! Stunning indeed!

And I love that wedge shape...sets it off a treat!

There will be a sneck on the iron...(or did I miss that bit)....set it off a treat.

I found with the yew bowsaw that the boiled linseed oil trick so loved by Bill is also wonderful if repeated for a long time...sit in front of twenty episodes of Poirot and just wipe it on lovingly while admiring your masterpiece.

You have set the standard way up there with the best of the old boys my friend....

Stand up and take a bow...Richard T --- MASTER Planemaker

Can't do infills indeed!!! :roll:

Bravo my dear friend...truly beautiful.

=D> =D> =D> =D> =D> =D>

Jimi

That is so GORGEOUS!!! Stunning indeed!

And I love that wedge shape...sets it off a treat!

There will be a sneck on the iron...(or did I miss that bit)....set it off a treat.

I found with the yew bowsaw that the boiled linseed oil trick so loved by Bill is also wonderful if repeated for a long time...sit in front of twenty episodes of Poirot and just wipe it on lovingly while admiring your masterpiece.

You have set the standard way up there with the best of the old boys my friend....

Stand up and take a bow...Richard T --- MASTER Planemaker

Can't do infills indeed!!! :roll:

Bravo my dear friend...truly beautiful.

=D> =D> =D> =D> =D> =D>

Jimi

tobytools

Established Member

Wow, I echo what jimi says. Truly beautiful work

TT

TT

"Can't beat the real thing" especially when it's this well made.

Any good ? (2.25" so prob not) and in Oz.

http://www.ebay.co.uk/itm/Snecked-iron- ... 19e8ce5304

Any good ? (2.25" so prob not) and in Oz.

http://www.ebay.co.uk/itm/Snecked-iron- ... 19e8ce5304

Richard T

Established Member

Thanks for finding that iron out Mr. P but no, too wide and too far. There is a chap who sells 2"ers in Scotland ( I've lost all my old bookmarks so can't check) but it's easy enough to do myself for much less dosh. I think they were £50 a pop.

I am going to do the submersion thing with raw Linseed when I can get to the shop to get enough to do it and maybe go to a Tupperware party for the relevant container.

I'm working on a smaller one and really want to try a skew. Speaking of which, has anyone ever seen or heard of a mitre badger? I was thinking about the ultimate panel raiser and a constructive use of old slotted irons .. just rambling out loud ...

I am going to do the submersion thing with raw Linseed when I can get to the shop to get enough to do it and maybe go to a Tupperware party for the relevant container.

I'm working on a smaller one and really want to try a skew. Speaking of which, has anyone ever seen or heard of a mitre badger? I was thinking about the ultimate panel raiser and a constructive use of old slotted irons .. just rambling out loud ...

Speaking of Scotland

Modern

http://www.holteyplanes.com/blog/2009/1 ... tre-plane/

http://www.petermcbride.com/planemaking/page1.htm

Blimey never heard of this talented artist before

http://www.flickr.com/photos/justinbkel ... 488917306/

1 antique

http://www.infill-planes.com/68/holland ... tre-plane/

Modern

http://www.holteyplanes.com/blog/2009/1 ... tre-plane/

http://www.petermcbride.com/planemaking/page1.htm

Blimey never heard of this talented artist before

http://www.flickr.com/photos/justinbkel ... 488917306/

1 antique

http://www.infill-planes.com/68/holland ... tre-plane/