Hi Biskit,

I use a electric fan heater to provide heat when in the shop when working... It is one of the Machine Mart fans with a thermostat so you can control the temperature. With the 50mm Celotex insulation all round it warms up quickly, stays pretty warm for quite a while too, before the heater tops it up from time to time. In the summer, the insulation works well to keep the hot sun at bay and its nice and cool in there.

I have not worried too much about heat at nighttime but think it may perhaps be wise to pop a couple of those tubular greenhouse heaters in there, as you have. All the cast machine tops are regularly coated with machine wax and so I don't usually have any problems.

I would love to have a woodburning stove but it would not be possible in my location. Do you put a kettle on the woodturner and toast your cheese sandwiches on it? 8) .... As a apprentice, I had the job of making up and lighting the sawdust burners each day in the winter; the red glow from the lid of those kept us really warm in winter. Tea and toasted sandwiches at lunchtime too ... those were the days

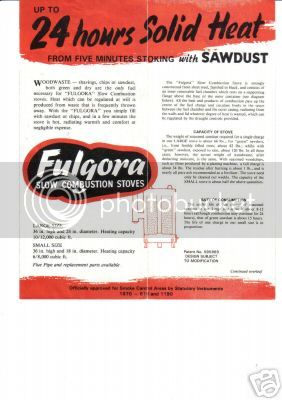

I don't know if those stoves are still available but the design and efficiency was brilliant. They comprised a outer shell in thick steel which was about 2 feet in diameter with a heavy lid. It had a flue outlet in the back, connected to the chimney and a sliding vent at bottom in the the front. It stood on metal legs and then a couple of concrete slabs. Inside that, again on legs, stood another 'drum' which gave air space of about 2" all round between inner and outer drums. At the bottom and centre of the inner drum was a 4" hole into which a metal tube fitted. You put the tube in the hole and filled the inner drum with sawdust, ramming it down to compact it. When full, remove the tube to leave a hole in the centre. Whack the lid on and light a few shavings in the bottom vent hole to get it started and the flames rose through the hole to burn the sawdust from the top down. It lasted about six hours before going out. It was a good way to get rid of the sawdust and shavings too! :mrgreen:

J.