Well thanks to Rich yet again I have extended my capabilities in the workshop.

First I now have a band saw, which although a little damaged during transportation, is now up and running and has been used to make blanks for some of my latest bowls.

And I also have a dust extraction unit, which makes a vast difference especially when sanding. (Still use a dust mask though).

Work bench stll needs a little improvement, but this works for now.

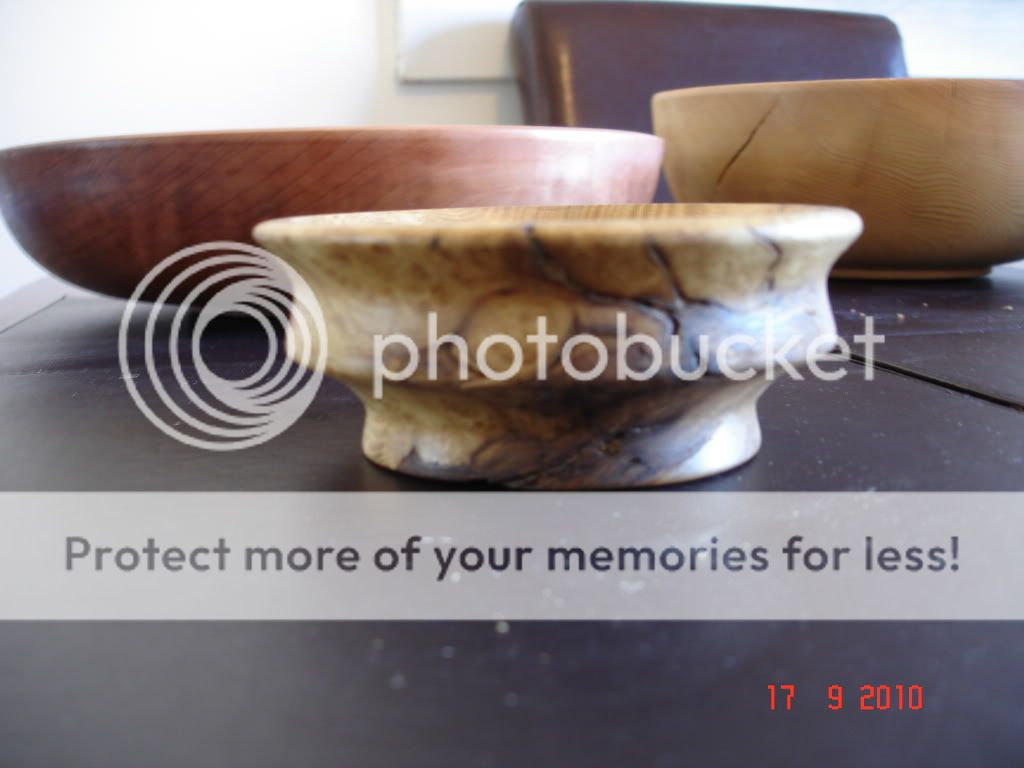

Having gathered together this equipment I have also had some fun using it to turn bowls from various types of wood and from small 41/2 “ x 2” to a little larger 12” x 4”. All great fun and different, so expanding my learning and experience.

The large bowl with a knot on one side was particularly fun as the knot throw the bowl out of balance and had the Union Graduate moving around !

It also flew of the chuck a couple o time whilst turning the inside, whih kept me on my toes.

This little bur was also fun to do as the bur was very deep and hence the shape evolved.

First I now have a band saw, which although a little damaged during transportation, is now up and running and has been used to make blanks for some of my latest bowls.

And I also have a dust extraction unit, which makes a vast difference especially when sanding. (Still use a dust mask though).

Work bench stll needs a little improvement, but this works for now.

Having gathered together this equipment I have also had some fun using it to turn bowls from various types of wood and from small 41/2 “ x 2” to a little larger 12” x 4”. All great fun and different, so expanding my learning and experience.

The large bowl with a knot on one side was particularly fun as the knot throw the bowl out of balance and had the Union Graduate moving around !

It also flew of the chuck a couple o time whilst turning the inside, whih kept me on my toes.

This little bur was also fun to do as the bur was very deep and hence the shape evolved.