Hi,

Picked up this plane on ebay as I was after a jointer to add to my no.4 and no. 5 Bailey style, but thought I'd try a wooden one:

After eventually managing to get the blade out and sharpen/hone it (as was pretty dull), when it came to setting it up I ran into a couple of issues...

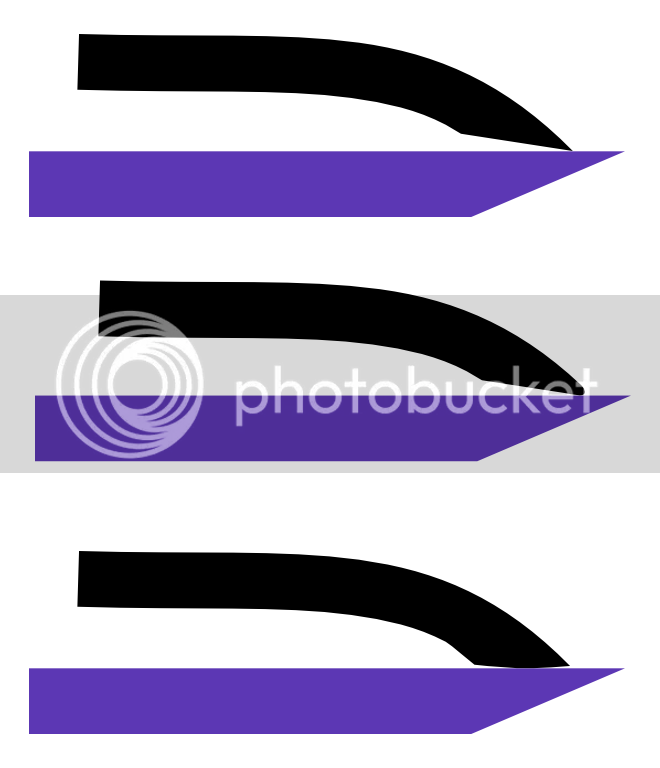

Firstly, the blade seems too close to the front edge of the mouth so when I take a shaving it just clogs up. Does this look too close (you can see clogged bits in centre of blade)?:

To be honest I can't see how I can adjust it so that there would be a wider gap as there is no fore/aft adjustment as with a metal Bailey style plane.

The second problem (and I appreciate this may impact the first issue) is that there is a slight hollow, about 1" wide, that runs in front of and behind the blade/mouth for a good few inches either side.

So how do I go about flattening the sole and Worthington the mouth opening issue?

Any help/suggestions much appreciated.

Cheers,

Jonny

Sent from my Nexus S using Tapatalk

Picked up this plane on ebay as I was after a jointer to add to my no.4 and no. 5 Bailey style, but thought I'd try a wooden one:

After eventually managing to get the blade out and sharpen/hone it (as was pretty dull), when it came to setting it up I ran into a couple of issues...

Firstly, the blade seems too close to the front edge of the mouth so when I take a shaving it just clogs up. Does this look too close (you can see clogged bits in centre of blade)?:

To be honest I can't see how I can adjust it so that there would be a wider gap as there is no fore/aft adjustment as with a metal Bailey style plane.

The second problem (and I appreciate this may impact the first issue) is that there is a slight hollow, about 1" wide, that runs in front of and behind the blade/mouth for a good few inches either side.

So how do I go about flattening the sole and Worthington the mouth opening issue?

Any help/suggestions much appreciated.

Cheers,

Jonny

Sent from my Nexus S using Tapatalk