Aled Dafis

Established Member

Hi, I've been using a Trend Diamond Stone and a Norton 8000 grit waterstone as my honing setup, but the Trend stone seems to be getting towards the end of it's life and has severely lost it's bite. I therefore decided to give my old 800/6000 grit waterstone another go the other night, and was stunned by how fast it cut compared to the Trend.

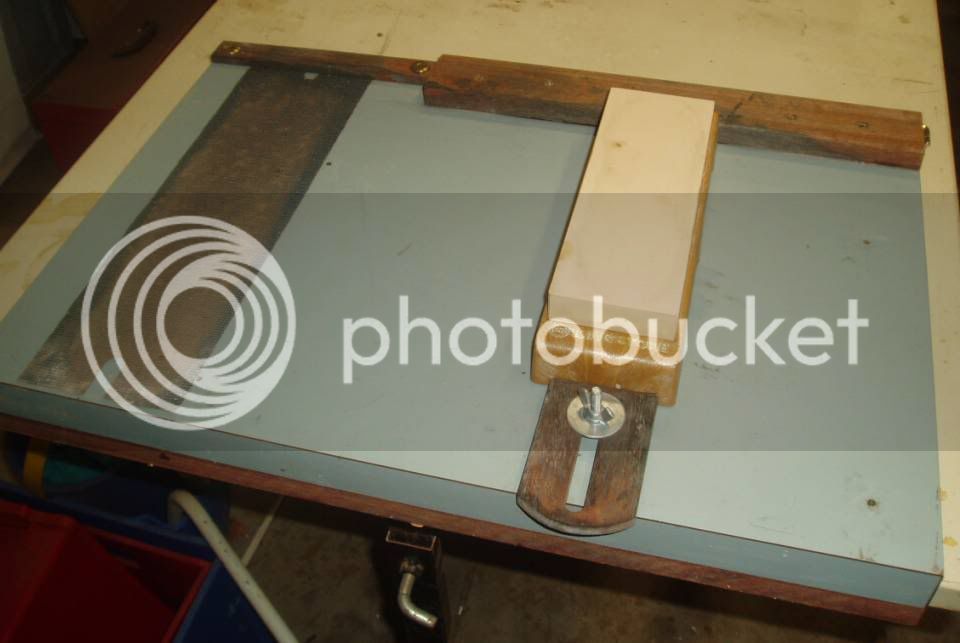

I've now decided to give Waterstones another go, so I was wondering if anybody has ideas as to a simple sharpening station that I could put together. I don't have a sink in the workshop, so the unit would need to be self contained, and preferably include a flattening area as well. I dont have much room so I'm thinking along the lines of a board with a couple of tupperware boxes.

You ideas and pics will be much appreciated as always.

Cheers

Aled

I've now decided to give Waterstones another go, so I was wondering if anybody has ideas as to a simple sharpening station that I could put together. I don't have a sink in the workshop, so the unit would need to be self contained, and preferably include a flattening area as well. I dont have much room so I'm thinking along the lines of a board with a couple of tupperware boxes.

You ideas and pics will be much appreciated as always.

Cheers

Aled