Mreagleeyes

Established Member

Hello all, been busy so only been browsing what's been going on.

Finally have a few coins in the bank and have started thinking about giving Bent Ply Furniture a go and on that note was wondering what peoples thought's where on the process of bending ply.

I've found the http://shop.instant-shop.com/bagpress/category80374.htm

web site and fairly happy with what ply to use.

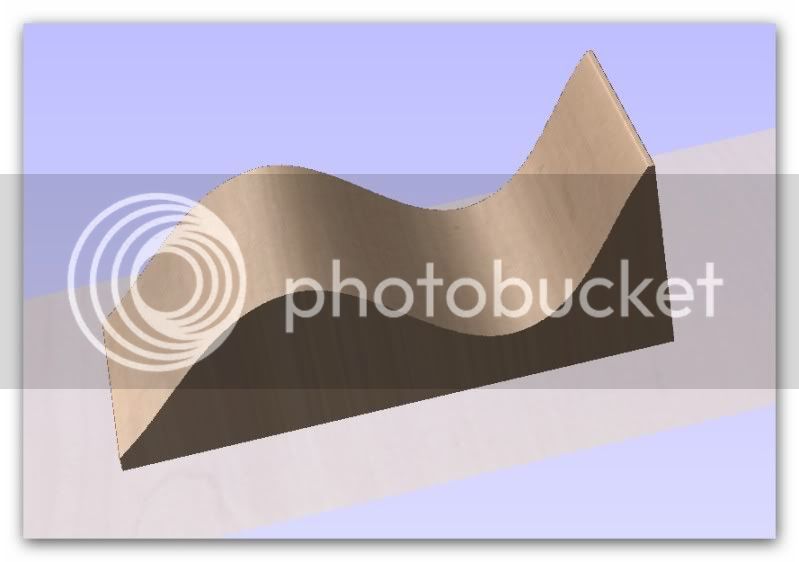

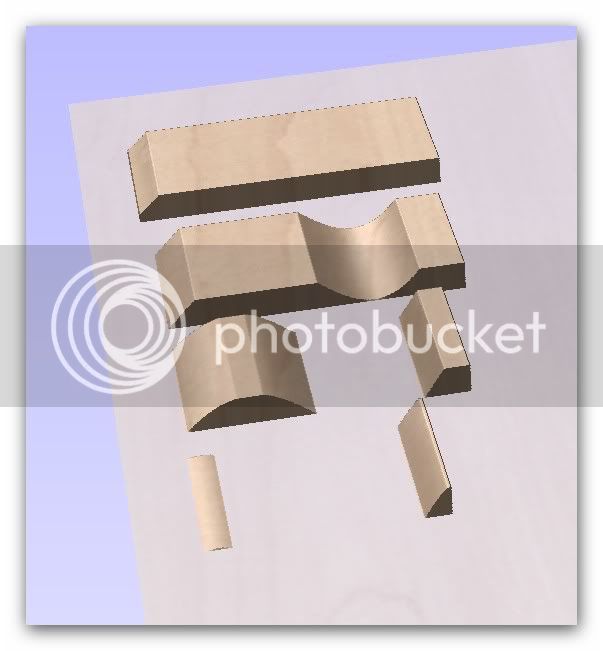

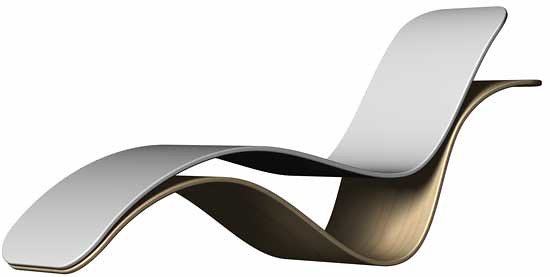

My question is. Is it worth me buying a Bag Press to try and create something similar to this

Or would I be better of just creating a large MDF continuous former and clamping it to death.

In the picture the curves are quiet deep and I'm not sure a Bag Press will be able to 'Stretch' that deep.

I'm thinking of going along the Eames design of furniture with my own twist.

Here is the Bag Press I am considering.

http://www.axminster.co.uk/bagpress-pro ... rc=froogle

Finally have a few coins in the bank and have started thinking about giving Bent Ply Furniture a go and on that note was wondering what peoples thought's where on the process of bending ply.

I've found the http://shop.instant-shop.com/bagpress/category80374.htm

web site and fairly happy with what ply to use.

My question is. Is it worth me buying a Bag Press to try and create something similar to this

Or would I be better of just creating a large MDF continuous former and clamping it to death.

In the picture the curves are quiet deep and I'm not sure a Bag Press will be able to 'Stretch' that deep.

I'm thinking of going along the Eames design of furniture with my own twist.

Here is the Bag Press I am considering.

http://www.axminster.co.uk/bagpress-pro ... rc=froogle