[email protected]

Established Member

Hi I have a Kity 1619 and wanted to buy a miter bar to make a crosscut sledge I understand that the ts200 is similar.

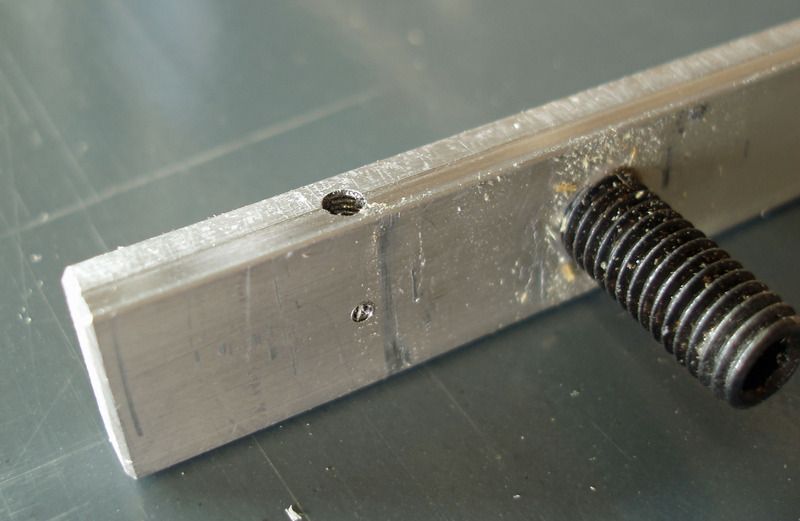

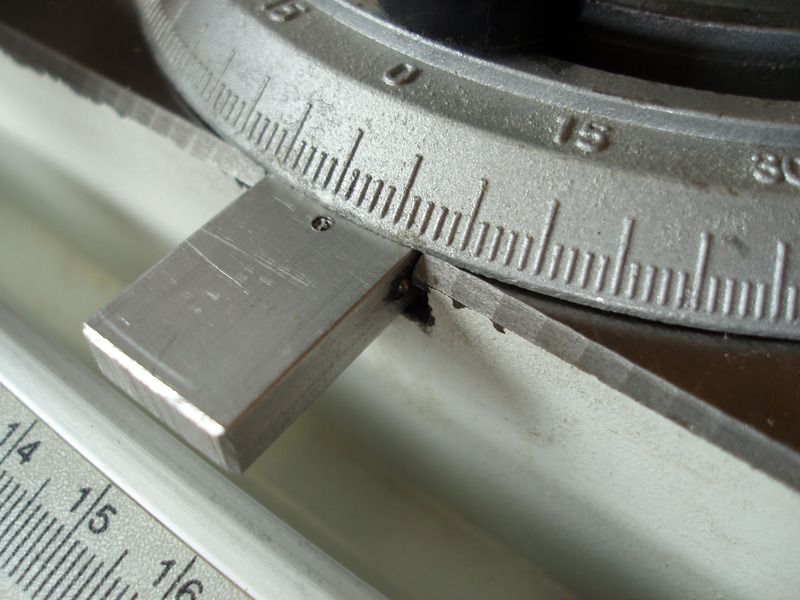

My Current bar measures 15.2 mm at the narrow width and 17.8 mm at the widest width.

Does anyone know the measurements of the ts200 or have a sorce where I could buy similar miter bar?

Many thanks

Rich

My Current bar measures 15.2 mm at the narrow width and 17.8 mm at the widest width.

Does anyone know the measurements of the ts200 or have a sorce where I could buy similar miter bar?

Many thanks

Rich