bugbear

Established Member

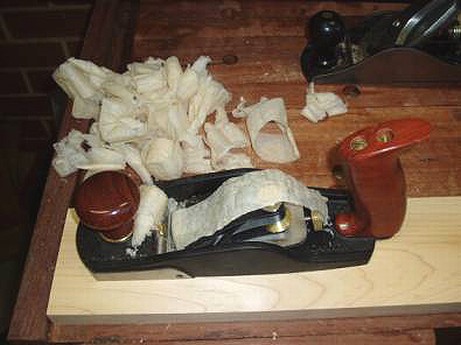

Both a close-enough cap-iron and the high enough effective pitch

will reduced tearout. Are the mechanisms (in fact) the same,

or do they work in different ways to achieve the same result?

On the face of things, it seems "quite reasonable" that adding a cap iron with a 20 degree

bevel to a plane iron at 45 might behave very similarly to a single iron bedded at 65 degree.

I am aware that most of the "cap iron conversation" took place on US and AUS

forums, so the answer to this might be well known, so any links

to previous discussions would be just as good as laboriously typed out answers,

BugBear

will reduced tearout. Are the mechanisms (in fact) the same,

or do they work in different ways to achieve the same result?

On the face of things, it seems "quite reasonable" that adding a cap iron with a 20 degree

bevel to a plane iron at 45 might behave very similarly to a single iron bedded at 65 degree.

I am aware that most of the "cap iron conversation" took place on US and AUS

forums, so the answer to this might be well known, so any links

to previous discussions would be just as good as laboriously typed out answers,

BugBear