Alan Smith

Established Member

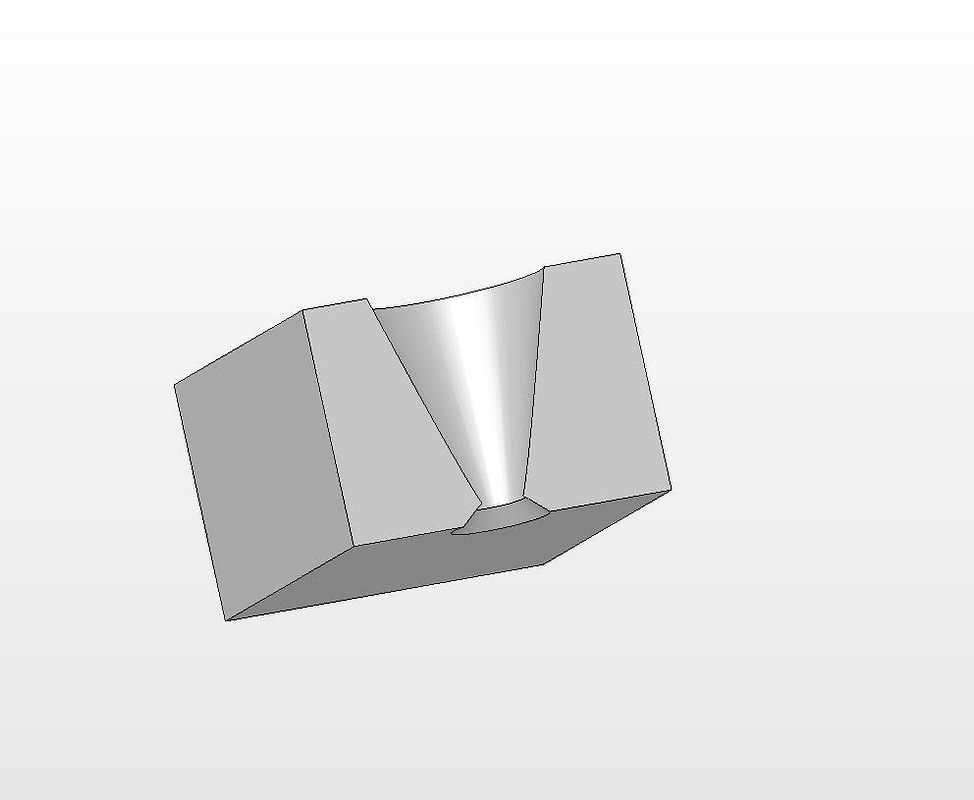

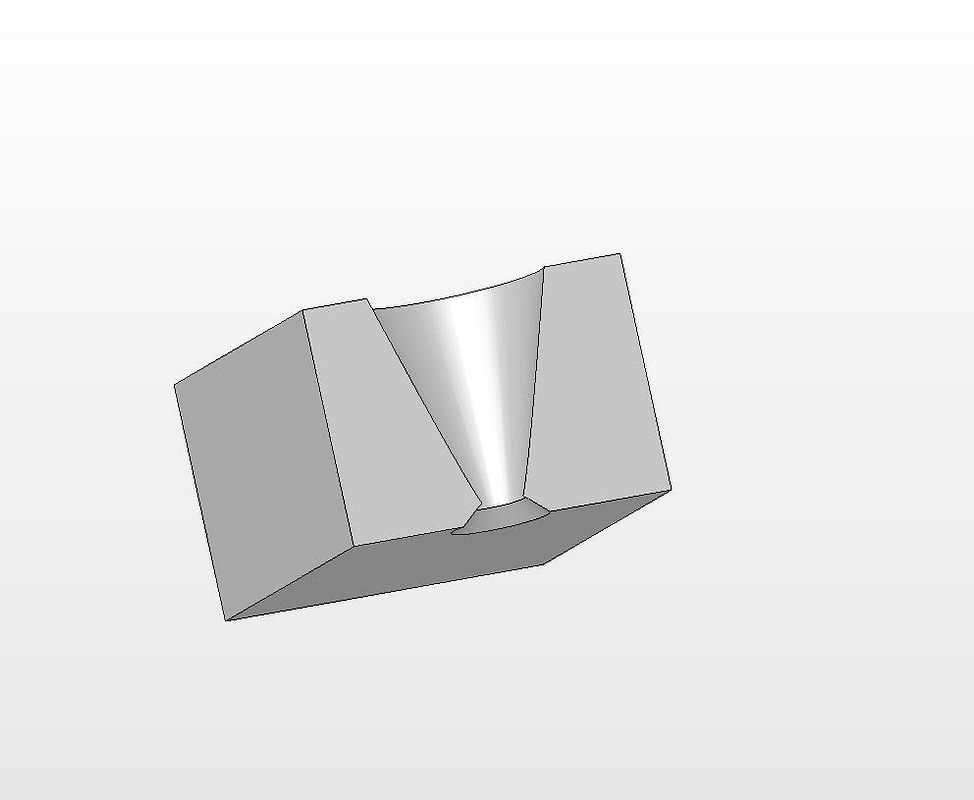

One of the things I hate doing is routing or boring oval holes in cleats to allow for movement in table tops etc. I came up with the following idea recently, it's quick and easy to do and seems to work well. First I drill a countersunk pilot hole through from the underside thn flip over the cleat and drill down following the pilot hole with a conecut which is a conical cutting tool for cutting holes of varying size in sheet metal. The image below shows a cross section.

I'm not claiming this is any better than routing an oval hole just that I find it easier to rattle this off on the drill press rather than mess about with the router.

I'm not claiming this is any better than routing an oval hole just that I find it easier to rattle this off on the drill press rather than mess about with the router.