Woodielanger

Member

Just a simple one this time... :lol:

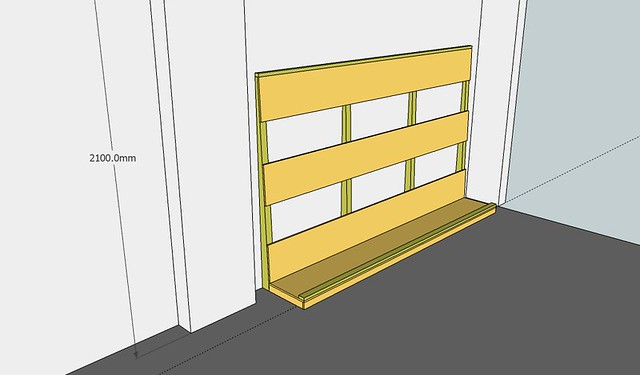

We have a wood rack about 4' wide and 4' high and 8' deep to store sheets in flat ( so the short end is showing). Even though we made about 4 levels to lay boards flat on, it's a pain to get a sheet out as the one you want is always under something!

My collegue said we should stand the boards up on the long edge ( to be 4' high) so we can pull out any size at any point. I'm not so sure as I like boards being flat.

What's the vote ? :? We can only access the short end of the board due to space.

Many thanks in advance

We have a wood rack about 4' wide and 4' high and 8' deep to store sheets in flat ( so the short end is showing). Even though we made about 4 levels to lay boards flat on, it's a pain to get a sheet out as the one you want is always under something!

My collegue said we should stand the boards up on the long edge ( to be 4' high) so we can pull out any size at any point. I'm not so sure as I like boards being flat.

What's the vote ? :? We can only access the short end of the board due to space.

Many thanks in advance