Wizard9999

Established Member

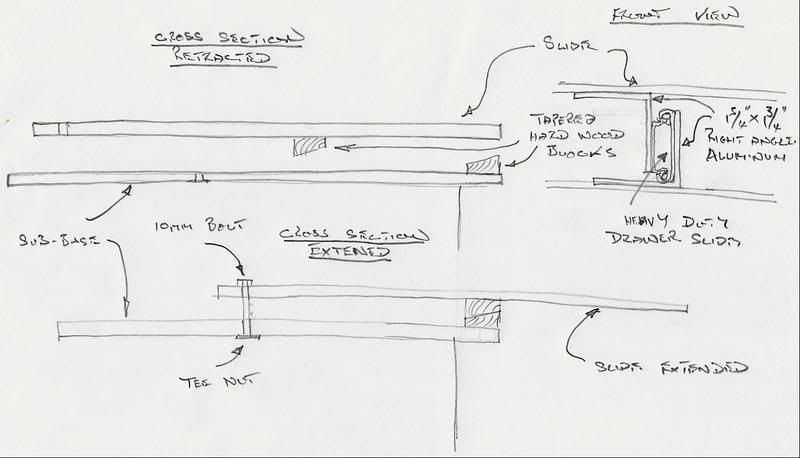

sawdust maker":1ici0xmw said:The next step is to position two bolts at the back of the slide. They go through the slide and screw into Tee nuts set into the underside of the sub-base. As their job is to stop the back of the slid lifting, they pass through large square washers that spread the strain. The bolts also prevent any lateral movement of the slide.

Scanned Drawing.

Having been pointed to this thread on a current workshop thread I had a look as the idea is very clever; as I am in the process of building a workshop I am keen on 'collecting' smart workshop solutions.

All is clear to me, except one point. In the extract above you make mention of bolts attaching to tee nuts, as far as I understand what you have built you would need to screw these bolts into the tee nuts every time you extend the slide. Is this correct or have I missed another aspect of the design?

Terry.