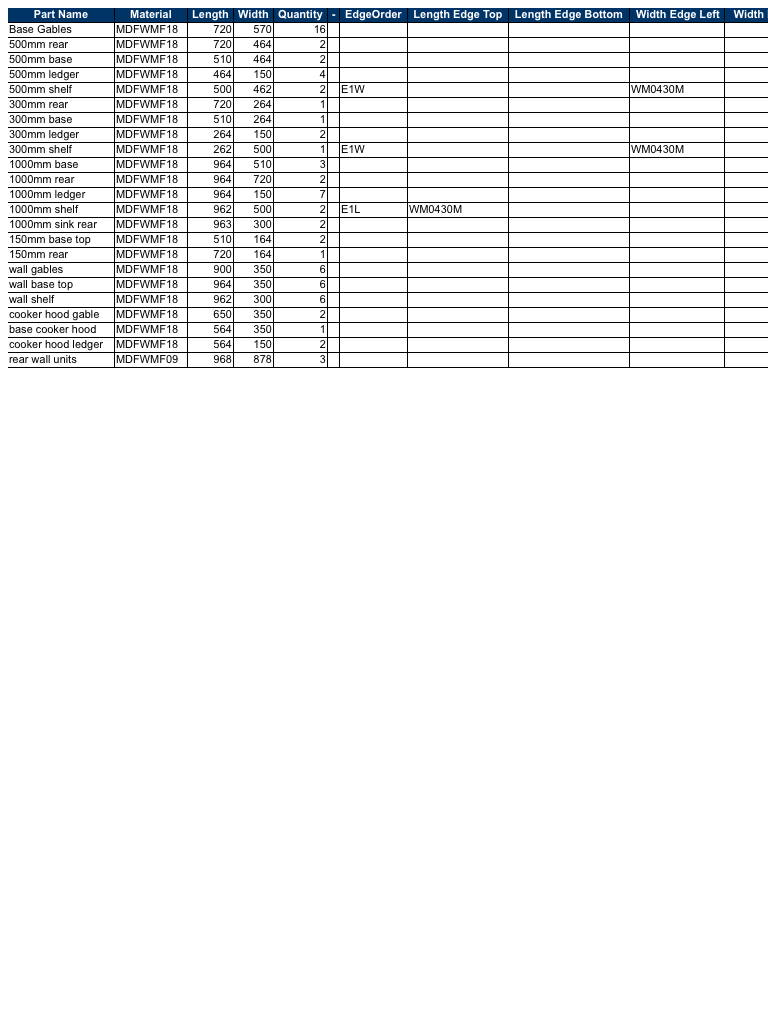

New year, new kitchen project. This one on a budget, with mfmdf and ply drawer boxes. Painted/sprayed face frame and popular doors on butts.

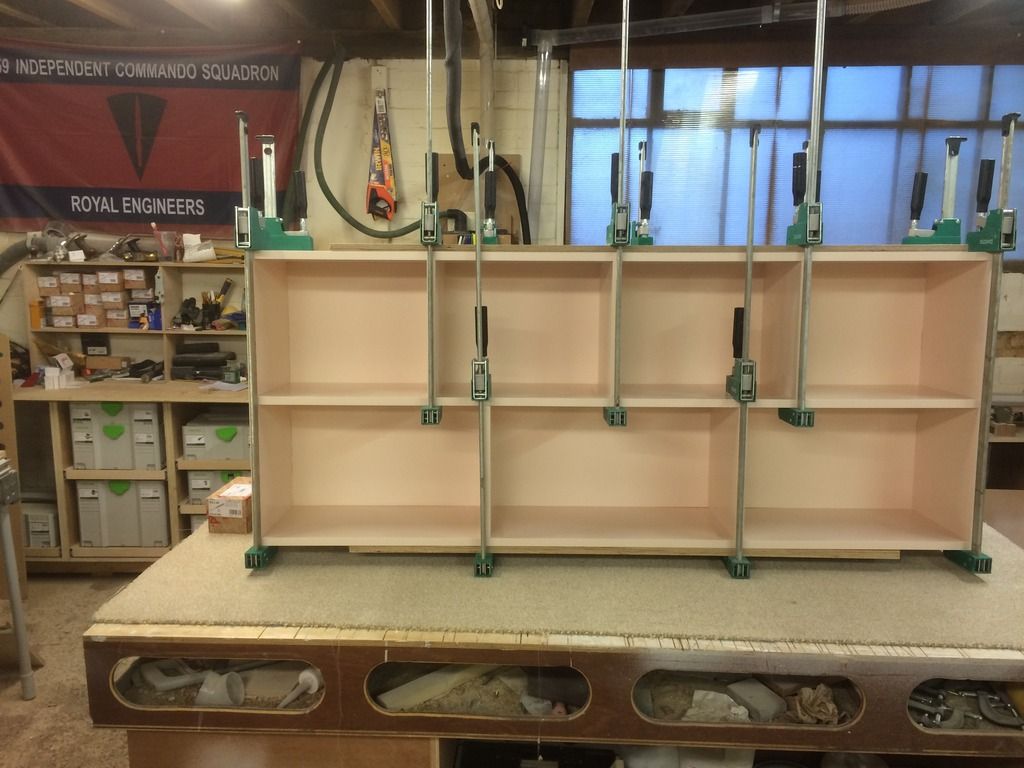

Domino's on gables for the base and top stretcher, rear panel and rear stretcher piloted and screwed.

On with the Kreg foremen, it really is fast. Front stretcher for face frame attachment.

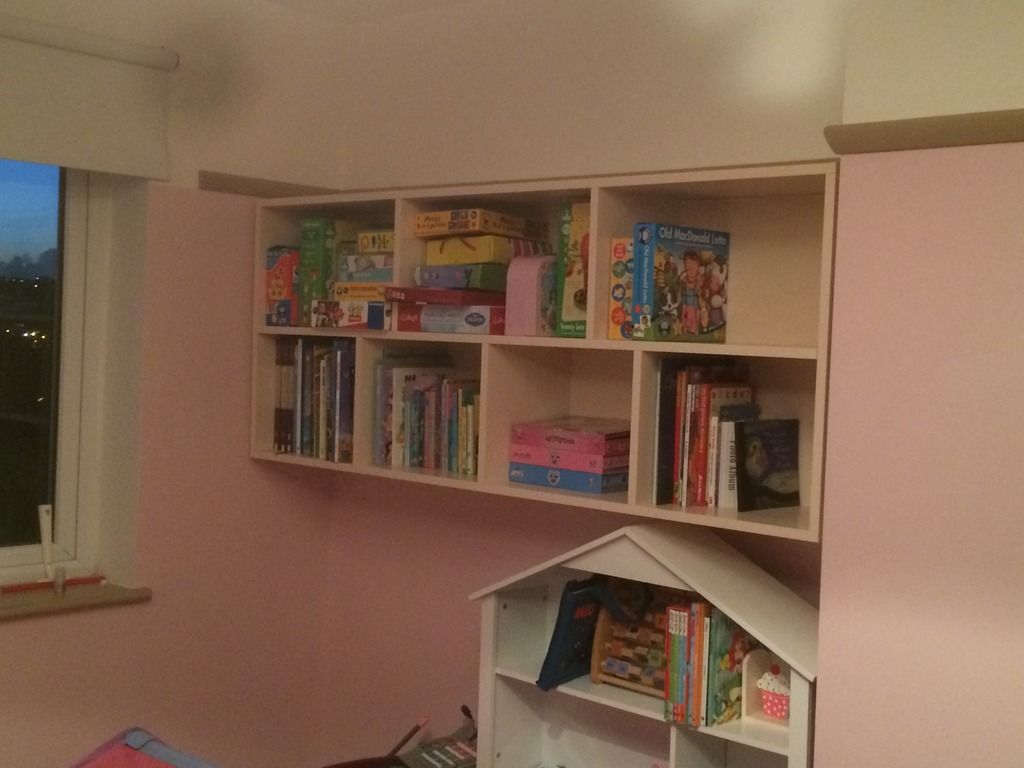

LR32 shelf pin holes, this is my friend Ross helping me out. He's getting paid!

Sink carcass assembled with removable backs that will be on hidden 15mm diameter magnets, not on yet.

All ready for more assembly tomorrow.

Half day so far. Will update as I can.

Domino's on gables for the base and top stretcher, rear panel and rear stretcher piloted and screwed.

On with the Kreg foremen, it really is fast. Front stretcher for face frame attachment.

LR32 shelf pin holes, this is my friend Ross helping me out. He's getting paid!

Sink carcass assembled with removable backs that will be on hidden 15mm diameter magnets, not on yet.

All ready for more assembly tomorrow.

Half day so far. Will update as I can.