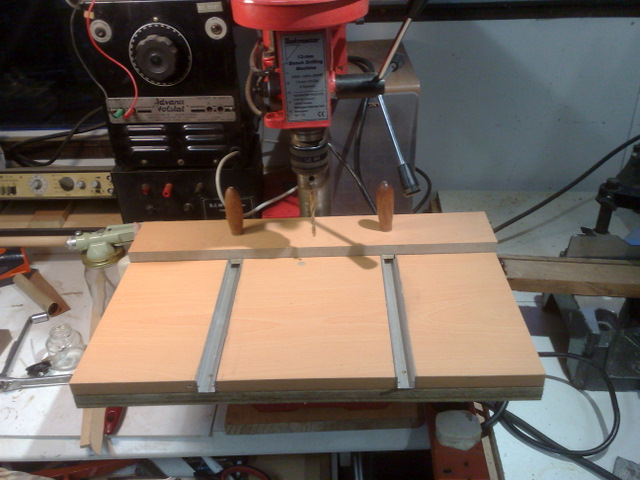

Bought a Jet 17 floor standing drill a couple of years ago and it's performed well and accurately, if noisily.

Read somewhere about those V link belts reducing vibration, so I got some when in Canada. That helped a bit. So did gaffer taping the lid down. But it was still noisy.

Today I had to move the drill to do an awkward job and noticed that the motor was mounted a few degrees off vertical, and the pulleys on the motor shaft were a little off level with the others. Doh.

So I sorted out the motor alignment and also stuck some P profile 'stormguard' around the lip of the lid.

What a difference! Night and day. Purrs quietly along now, and the loudest noise (almost) is the drill bit cutting.

Read somewhere about those V link belts reducing vibration, so I got some when in Canada. That helped a bit. So did gaffer taping the lid down. But it was still noisy.

Today I had to move the drill to do an awkward job and noticed that the motor was mounted a few degrees off vertical, and the pulleys on the motor shaft were a little off level with the others. Doh.

So I sorted out the motor alignment and also stuck some P profile 'stormguard' around the lip of the lid.

What a difference! Night and day. Purrs quietly along now, and the loudest noise (almost) is the drill bit cutting.