Ollie78

Established Member

Hi

I have recently picked up an old stanley 71 1/2 router plane, and a spare blade. (£5 for the plane £4 for spare blade)

The issue I have is sharpening the blades. It looks like the previous owner has been sharpening pretty freehand and the blade is far from square at the edge.

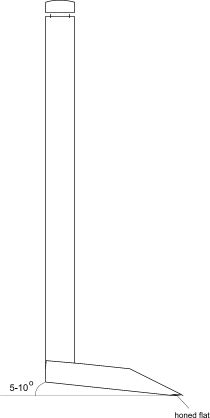

Obviously I have flattened the back but I am struggling with sharpening the bevel side.

Is there any tips for this, bearing in mind I have oil stones and water stones but no grinder.

Any tips welcome.

Cheers Ollie.

I have recently picked up an old stanley 71 1/2 router plane, and a spare blade. (£5 for the plane £4 for spare blade)

The issue I have is sharpening the blades. It looks like the previous owner has been sharpening pretty freehand and the blade is far from square at the edge.

Obviously I have flattened the back but I am struggling with sharpening the bevel side.

Is there any tips for this, bearing in mind I have oil stones and water stones but no grinder.

Any tips welcome.

Cheers Ollie.