Can someone please explain in simple terms the mechanics of using a scratchstock? Do you use it with a pushing motion or a pulling motion? How do you "sharpen" it? Any tips on making cutters?

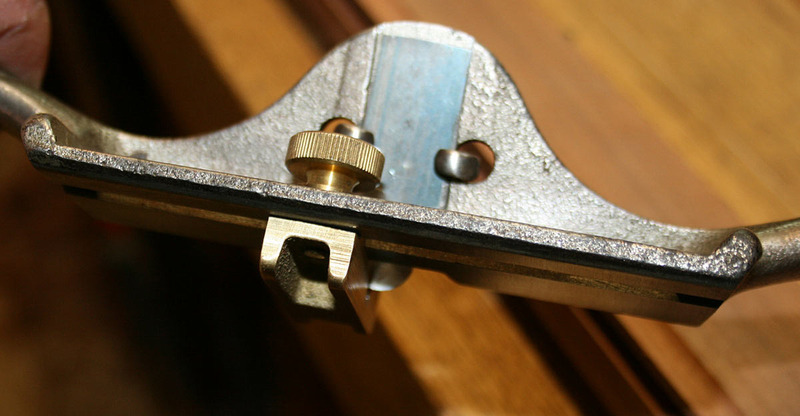

The background to my question is that I have made a scratchstock - basically a marking gauge that holds a shaped iron rather than a pin - and I am having problems using it effectively. Perhaps that is not surprising given that I have never even seen a scratchstock before.

So far I have done 2 tests. My first test was on a short scrap of pine. It did work but I had 2 issues. First, it took forever. Second, the quality of finish left a lot to be desired. For both reasons I doubt I would use this tool on a real project.

My second test was on a scrap of birch, so a harder wood than the pine. This was even slower than the test on pine, but the quality of the finished surface was much better. I would be happy with that finish on a project, so I hope there is some technique I can learn to make the work go faster. Or possibly I am being too ambitious with the shape of my cutter, which is 25mm wide with 4 hollows / 5 peaks. That was just a random shape I created for testing with.

The background to my question is that I have made a scratchstock - basically a marking gauge that holds a shaped iron rather than a pin - and I am having problems using it effectively. Perhaps that is not surprising given that I have never even seen a scratchstock before.

So far I have done 2 tests. My first test was on a short scrap of pine. It did work but I had 2 issues. First, it took forever. Second, the quality of finish left a lot to be desired. For both reasons I doubt I would use this tool on a real project.

My second test was on a scrap of birch, so a harder wood than the pine. This was even slower than the test on pine, but the quality of the finished surface was much better. I would be happy with that finish on a project, so I hope there is some technique I can learn to make the work go faster. Or possibly I am being too ambitious with the shape of my cutter, which is 25mm wide with 4 hollows / 5 peaks. That was just a random shape I created for testing with.