DavidE

Established Member

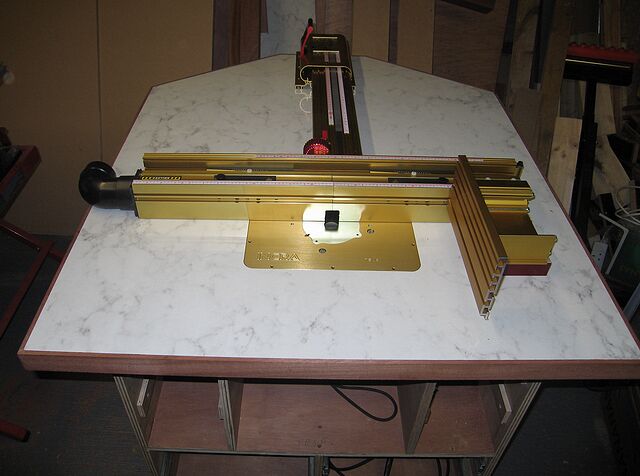

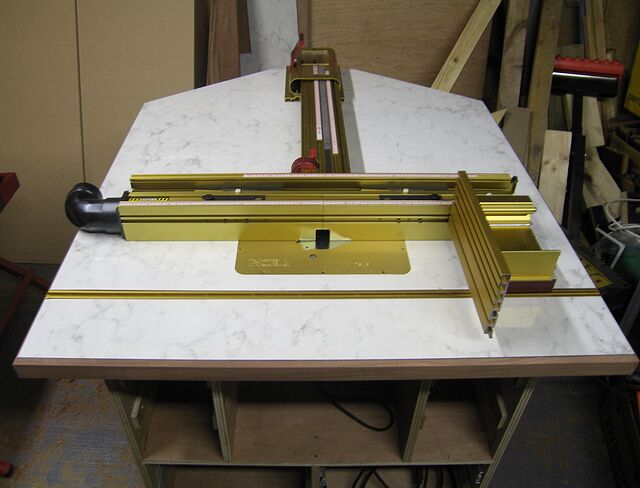

I started making a Router Table last weekend. It is designed in the Style of Norms, and collects all the nice features I have seen from the threads on here (especially our resident Lord, and MotownMartin). It is having a 17" LS positioner on it (I blame Martin for that  ). It started off life in Sketchup...

). It started off life in Sketchup...

I made the cabinet last weekend and didn't take any WIP shots, an oversight I know.

Anyway I thought it might be useful to take some today showing how I put the insert in. Yesterday two pieces of 18mm MDF and some fireback were glued together.

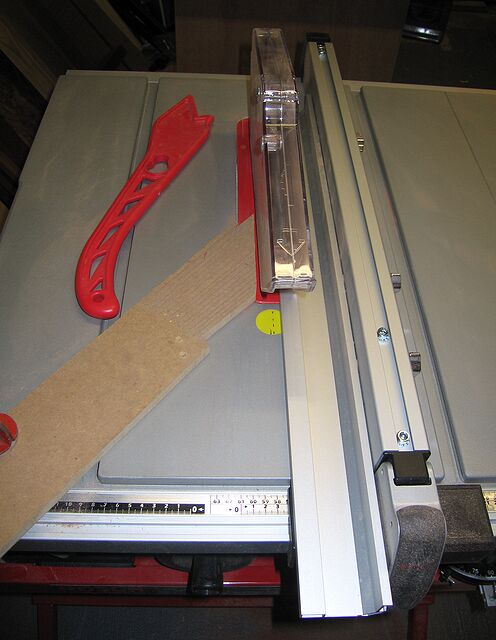

This is prior to trimming the edges down.

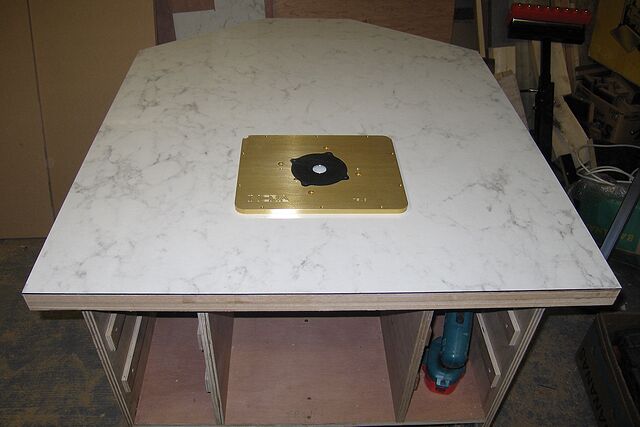

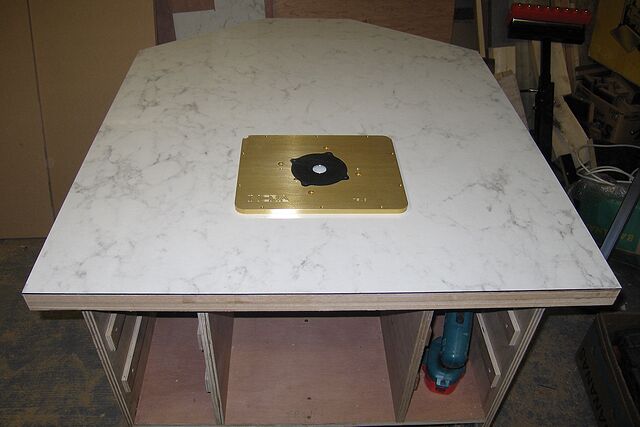

After the edges have been trimmed with the Incra Magnalock insert on top.

I got inspiration for making the template from here: http://lumberjocks.com/jocks/Blake/blog/2654 (Scroll down)

Though I changed it round a bit - still used a 1.5" Forstner Bit:

I avoided glueing by screwing the pieces to a piece of MDF underneath.

With the insert sat in:

Some MDF added to the middle to support the router:

After routing with the initial template removed the final template is underneath:

The insert was then double sided taped to the table and a piece made for the inner hole - I forgot to take photos round this time.

Anyhow with great relief routing is finished and the insert is a nice snug fit in the recess:

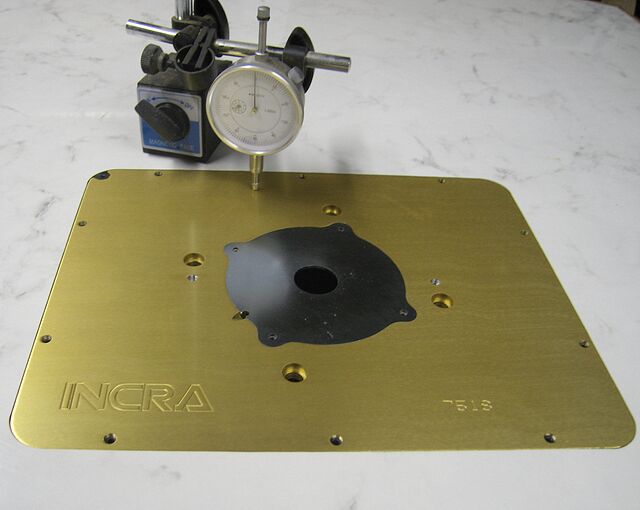

Shelf was cut around 2mm deeper than the plate to allow the levelling screws to do their stuff:

The backside of the table has just been varnished to ward off moisture and after the top of the cabinet is levelled will be fastened on tomorrow all being well. Then there is the hardwood lipping the T slot and the Incra to fit. Then it will be called into use to make its own drawers!

David

I made the cabinet last weekend and didn't take any WIP shots, an oversight I know.

Anyway I thought it might be useful to take some today showing how I put the insert in. Yesterday two pieces of 18mm MDF and some fireback were glued together.

This is prior to trimming the edges down.

After the edges have been trimmed with the Incra Magnalock insert on top.

I got inspiration for making the template from here: http://lumberjocks.com/jocks/Blake/blog/2654 (Scroll down)

Though I changed it round a bit - still used a 1.5" Forstner Bit:

I avoided glueing by screwing the pieces to a piece of MDF underneath.

With the insert sat in:

Some MDF added to the middle to support the router:

After routing with the initial template removed the final template is underneath:

The insert was then double sided taped to the table and a piece made for the inner hole - I forgot to take photos round this time.

Anyhow with great relief routing is finished and the insert is a nice snug fit in the recess:

Shelf was cut around 2mm deeper than the plate to allow the levelling screws to do their stuff:

The backside of the table has just been varnished to ward off moisture and after the top of the cabinet is levelled will be fastened on tomorrow all being well. Then there is the hardwood lipping the T slot and the Incra to fit. Then it will be called into use to make its own drawers!

David