chippy1970

Established Member

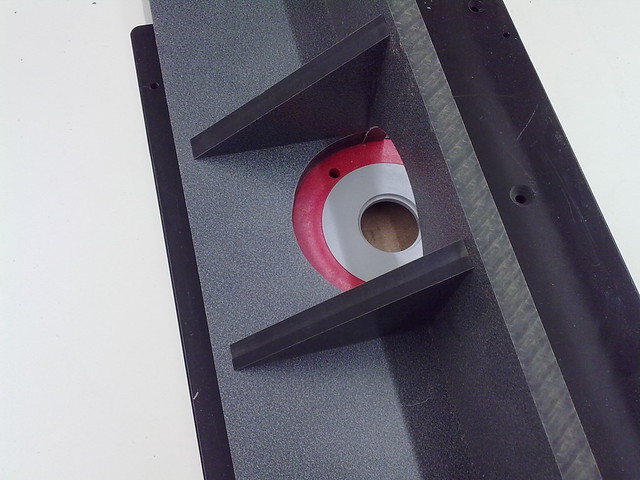

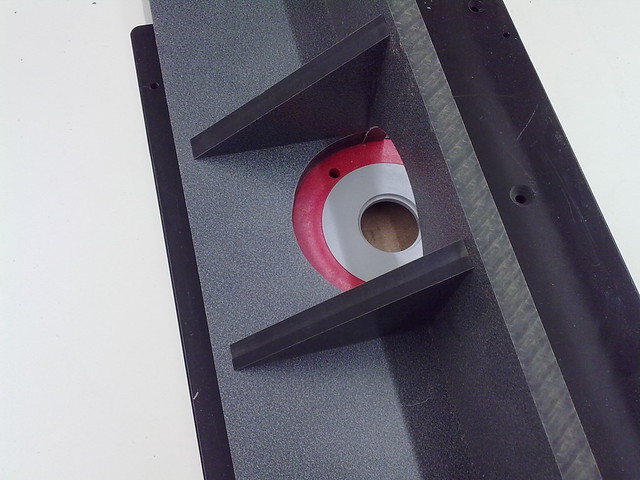

Well I have finally got around to starting a new router table its going to be a portable jobbie for workshop and on site use. Its going to hold my dw626, heres some quick photos, so far I have made a 25mm mdf top with oak edging then had it laminated both sides, routed the plate in using a bearing guided trim cutter and a homemade template. Then I have started knocking up a fence out of some offcuts of toilet cubicle (phenolic plastic) that I had knocking around. The fence will have sliding faces, a t slot and extraction when finished.