woodbloke

Established Member

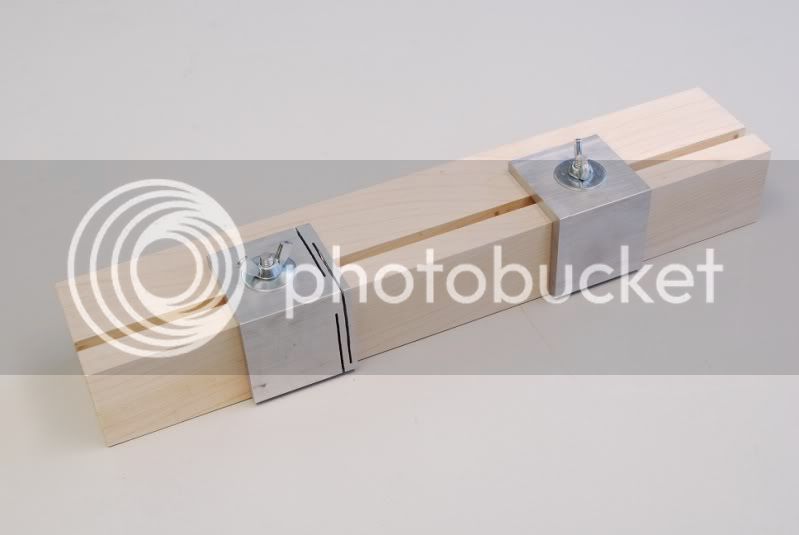

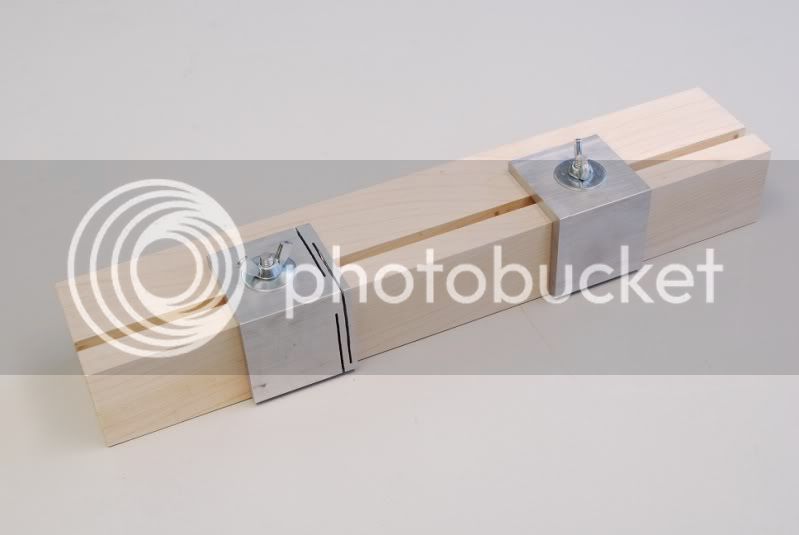

It being a wet Bank Holiday Saturday afternoon :roll: I thought I'd knock up a Robert Ingham dovetail transference jig. In his book, he uses mdf as the main woodie material, but as I didn't have anything quite so esoteric as that so I've used an oddment of rock maple instead:

The two aluminium angle brackets are made from some 50x50x6mm thick stuff (bought from Ringwood Precision Engineers, see also their ebay site) and had to be made dead square, didn't take as long as I though it would.

They're held in with a couple of sliding 'T' nuts made from a bit of old 6mm bolt to form the studding and some gash 10mm mild steel strip, the 'T' slot was made with a suitable cutter from Axminster. Having got hold of some Zona razor saws at Yandles in April I ought to be able to cut some half-respectable dovetails now...I just need some decent dovetail chisels.

Matthew? :wink: :lol: - Rob

The two aluminium angle brackets are made from some 50x50x6mm thick stuff (bought from Ringwood Precision Engineers, see also their ebay site) and had to be made dead square, didn't take as long as I though it would.

They're held in with a couple of sliding 'T' nuts made from a bit of old 6mm bolt to form the studding and some gash 10mm mild steel strip, the 'T' slot was made with a suitable cutter from Axminster. Having got hold of some Zona razor saws at Yandles in April I ought to be able to cut some half-respectable dovetails now...I just need some decent dovetail chisels.

Matthew? :wink: :lol: - Rob