DougieH

Established Member

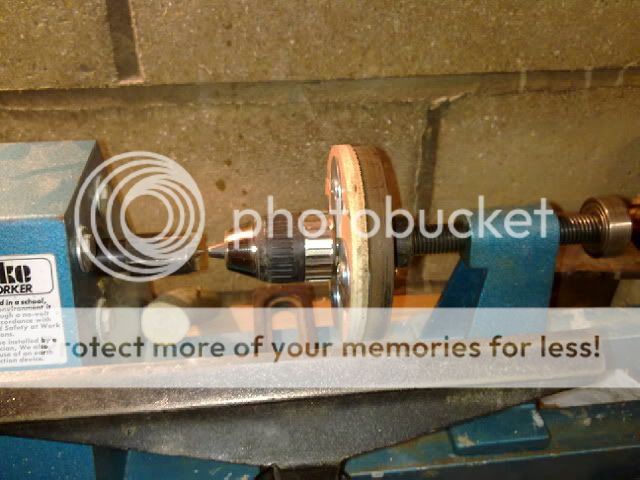

Hi, just thought I would say a quick hello. I have just set up the Clarke CWL6 that has been sitting in my garage wrapped in a tarp, since I inherited it about 12 years ago. Ive worked with wood a bit (a couple of longbows and a 14ft plywood canoe, can be seen on www.songofthepaddle.co.uk just search DougieH, if interested). Had a bit of a play over the hols and the following are attempts 1 and 2. The bowl is eucalyptus, turned wet, about 3in by 1in. The vase is poplar, dry and appox 5in by 3in. Both finished in vaseline BP. The reason for the poplar is because I had two large poplars taken down a couple of years ago, so have lots of it. I only have 20mm and 13mm skews and a 13mm shallow fluted gouge at the moment, but the local toolshop opens on the 6th so will be spending a few Xmas pennies.

I have a question if I may. Is it possible to fit a drill chuck to the tailstock on the Clarke. It seems to be an unusual size, approx 10tpi by 20mm, and its not hollow. I have a 3 jaw chuck and some faceplates, but fancied the versatility of the drill chuck. I also fancy trying pens.

Sorry for the ramble and the poor pics, and thanks for reading, and all advice will be much appreciated.

Doug

I have a question if I may. Is it possible to fit a drill chuck to the tailstock on the Clarke. It seems to be an unusual size, approx 10tpi by 20mm, and its not hollow. I have a 3 jaw chuck and some faceplates, but fancied the versatility of the drill chuck. I also fancy trying pens.

Sorry for the ramble and the poor pics, and thanks for reading, and all advice will be much appreciated.

Doug