DiscoStu

Established Member

I bought a Parf Guide System as soon as it was announced last year and today I finally got round to opening the packet!

I thought I'd share my thoughts on it.

For those that don't know it's a system for creating 20mm holes in a perfectly square pattern in wood. This is ideally used with parf dogs to create cutting tables for use with track saws (like the Festool MFT).

Inside the package you get:

2 x 1m rules with pre drilled 3mm holes

3 x 3mm pins

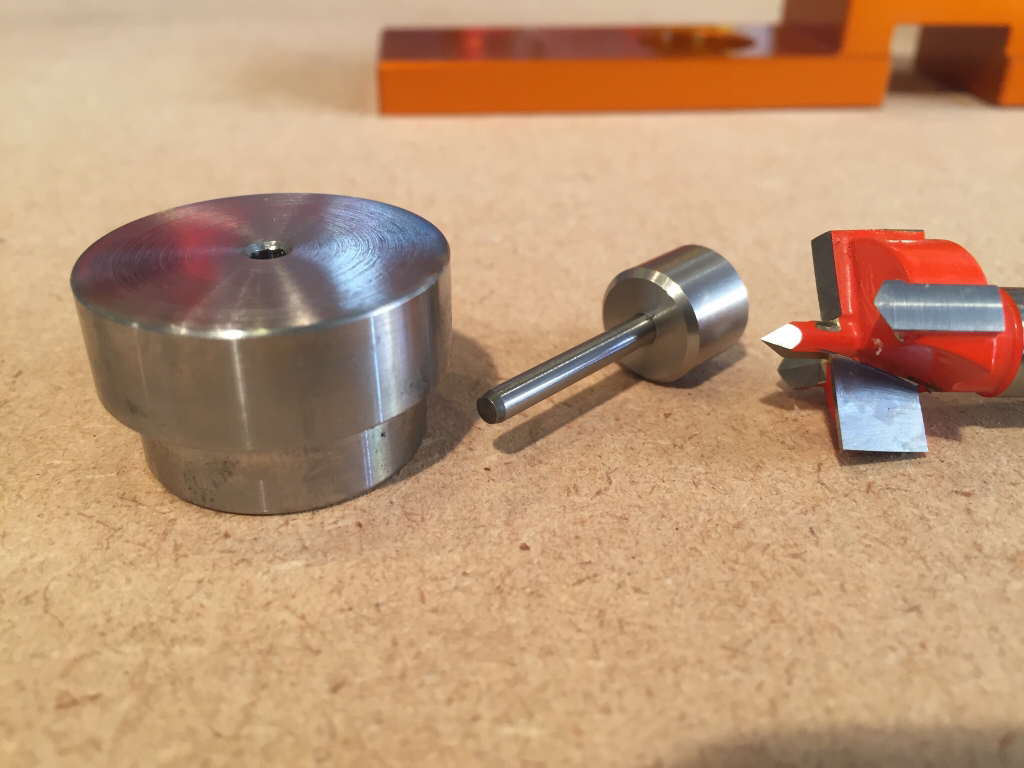

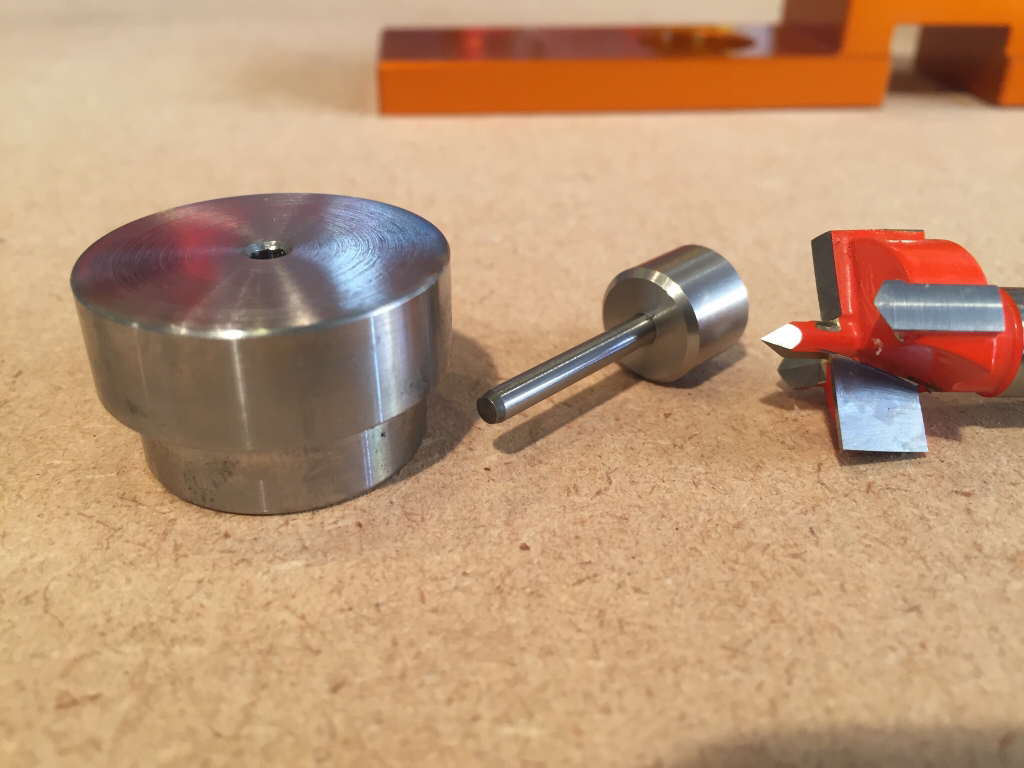

1 x 20mm forstner style bit (although it's specific to this set)

1 x 3mm drill bit

1 x 3mm drill guide

1 x 20mm drill guide (The big orange thing)

1 user guide

So my first thoughts are that it is a well made high quality precision tool. It oozes quality and tight tolerances. The supplied manual is clear, detailed and is a world apart from most of the manuals we see, although it's on a par with other manuals I've seen from UJK.

It's easy to set it up and to get you first row of 3mm holes. The guide for the 3mm hole helps keep the drill vertical. I had an old piece of 18mm MRMDF lying about so I used this for my test. I clamped a parf stick (Steel ruler with pre drilled holes) down to the MDF and drilled my first 3mm holes. I then swung it around roughly 90 degrees and using the 3/4/5 method set it accurately to a right angle (the manual clearly explains this so I'm not going into detail here). Once this was set I could do a set of vertical 3mm holes and then I repeated for the other side and top edge. I finally finished with another vertical set of holes in roughly the middle.

So 3mm holes all done I moved onto the 20mm holes. You use the pins and guide block to line up the 20mm cutter and away you go. I found that my 20mm cutter got clogged pretty quickly but my MDF was a bit old and going "furry". Once you've done a series of 20mm holes you have to use parf dogs to position the block as the points where the 3mm alignment holes were have become 20mm holes. You need to be aware that the 20mm parf dogs don't come with the system. Not that this is an issue as you'll be buying these to use with it anyway. For me it was a bonus as I already had parf dogs so I didn't feel like I was paying for them twice.

I did a 600 x 1000 sheet of MDF from start to finish in about an hour having never use the system before. I found the accuracy was excellent. The only downside was that the cutter kept clogging although this is likely to be the MDF. I did find that having a drill with removable chuck was incredibly useful although only my CXS has that feature and it's not the most powerful of drills.

After completing all of my holes I did a very quick check for square with a rail and it was spot on.

This was just a quick test to see how I got on with it and if it was accurate and it seems to be spot on.

I found the 20mm holes a bit of a pain but I am hopefully it's just old MDF stock.

I am intending to build a bench with this sort of top so it should be good for that.

I'd love to see a router version as I think that could be excellent.

Sent from my iPhone using Tapatalk

I thought I'd share my thoughts on it.

For those that don't know it's a system for creating 20mm holes in a perfectly square pattern in wood. This is ideally used with parf dogs to create cutting tables for use with track saws (like the Festool MFT).

Inside the package you get:

2 x 1m rules with pre drilled 3mm holes

3 x 3mm pins

1 x 20mm forstner style bit (although it's specific to this set)

1 x 3mm drill bit

1 x 3mm drill guide

1 x 20mm drill guide (The big orange thing)

1 user guide

So my first thoughts are that it is a well made high quality precision tool. It oozes quality and tight tolerances. The supplied manual is clear, detailed and is a world apart from most of the manuals we see, although it's on a par with other manuals I've seen from UJK.

It's easy to set it up and to get you first row of 3mm holes. The guide for the 3mm hole helps keep the drill vertical. I had an old piece of 18mm MRMDF lying about so I used this for my test. I clamped a parf stick (Steel ruler with pre drilled holes) down to the MDF and drilled my first 3mm holes. I then swung it around roughly 90 degrees and using the 3/4/5 method set it accurately to a right angle (the manual clearly explains this so I'm not going into detail here). Once this was set I could do a set of vertical 3mm holes and then I repeated for the other side and top edge. I finally finished with another vertical set of holes in roughly the middle.

So 3mm holes all done I moved onto the 20mm holes. You use the pins and guide block to line up the 20mm cutter and away you go. I found that my 20mm cutter got clogged pretty quickly but my MDF was a bit old and going "furry". Once you've done a series of 20mm holes you have to use parf dogs to position the block as the points where the 3mm alignment holes were have become 20mm holes. You need to be aware that the 20mm parf dogs don't come with the system. Not that this is an issue as you'll be buying these to use with it anyway. For me it was a bonus as I already had parf dogs so I didn't feel like I was paying for them twice.

I did a 600 x 1000 sheet of MDF from start to finish in about an hour having never use the system before. I found the accuracy was excellent. The only downside was that the cutter kept clogging although this is likely to be the MDF. I did find that having a drill with removable chuck was incredibly useful although only my CXS has that feature and it's not the most powerful of drills.

After completing all of my holes I did a very quick check for square with a rail and it was spot on.

This was just a quick test to see how I got on with it and if it was accurate and it seems to be spot on.

I found the 20mm holes a bit of a pain but I am hopefully it's just old MDF stock.

I am intending to build a bench with this sort of top so it should be good for that.

I'd love to see a router version as I think that could be excellent.

Sent from my iPhone using Tapatalk