First time poster long time reader!

Currently contemplating my first project now I have a house with a workshop, and wondering if I can pass off the need for built in wardrobes as an opportunity to buy over-priced tools :twisted:

Problem is I quite like my wife... :lol:

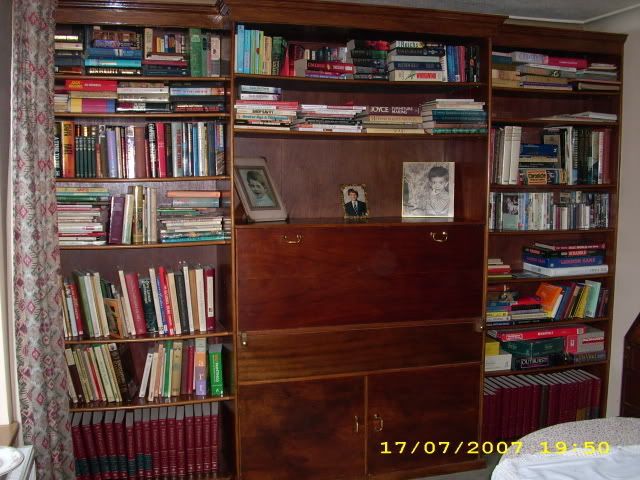

So, is something like the photo below by jasonB feasible as a first project? Clearly I won't get it done as well or as fast, but will I get it done reasaonably well before SWMBO is driven to divorce?

If I was going to go for it, it is mostly sheet materials isn't it? In which case I would be looking at a decent circular saw, biscuiter(/Domino) and router (table) and a few hand tools (together with drill which I already have). Will I struggle doing face frames without a table saw? And is there a good reason not to do these with laminated MDF when I'm painting it?

Any other thoughts and advice? Answers to WiZeR's questions in the post would be good too!

Currently contemplating my first project now I have a house with a workshop, and wondering if I can pass off the need for built in wardrobes as an opportunity to buy over-priced tools :twisted:

Problem is I quite like my wife... :lol:

So, is something like the photo below by jasonB feasible as a first project? Clearly I won't get it done as well or as fast, but will I get it done reasaonably well before SWMBO is driven to divorce?

If I was going to go for it, it is mostly sheet materials isn't it? In which case I would be looking at a decent circular saw, biscuiter(/Domino) and router (table) and a few hand tools (together with drill which I already have). Will I struggle doing face frames without a table saw? And is there a good reason not to do these with laminated MDF when I'm painting it?

Any other thoughts and advice? Answers to WiZeR's questions in the post would be good too!