Dangermouse

Established Member

- Joined

- 23 Dec 2010

- Messages

- 714

- Reaction score

- 0

Just thought I'd post a bit about a new bench I have been making, in between other stuff. It has a beech top and the legs and frame is some Victorian reclaimed pine. My other bench which I have had for more years than I care to remember, is falling to pieces now. It was only a cheap job and its lasted more than I thought, so I needed to get this bench up and running. All of this bench is being made with hand tools, not one single power tool has or will be used.

This was the first trial assembly, the joints are mortise and tennon, which will be pegged. the holes in the main member are from nails, I will fill them in and sand down to finish off.

I did not use through tennons, with pegs I thought it would be plenty strong enough and looks better. The stretchers are flush with the top of the leg to support the top.

The front part of the top is made of three inch thick beech with a pine length at the back, then I will put a tool well at the rear. The top has been mortise and tennoned onto the legs

I will use wedges to fix the tennons in the top.

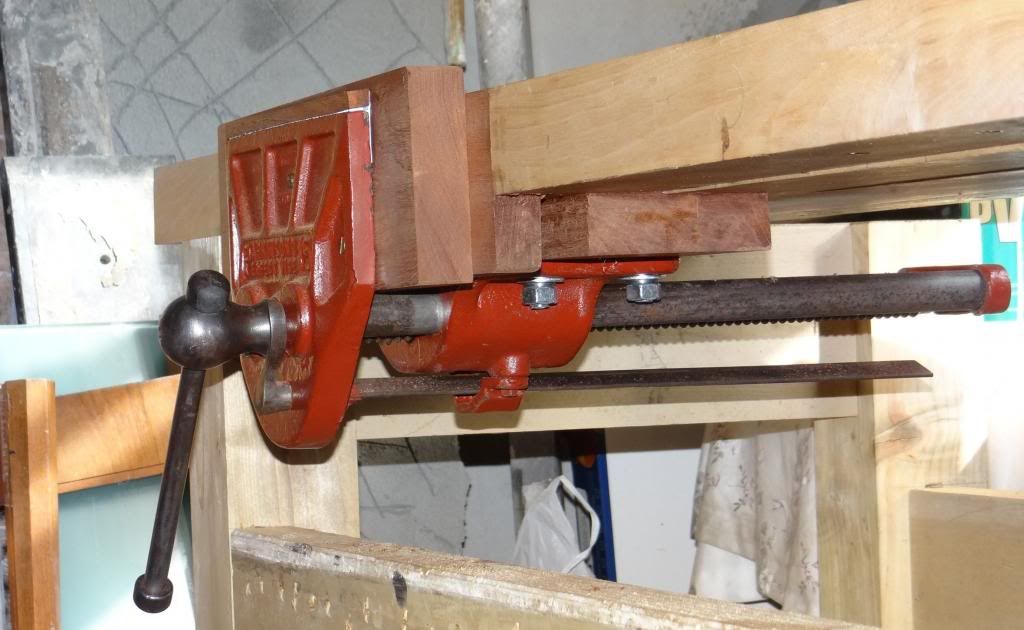

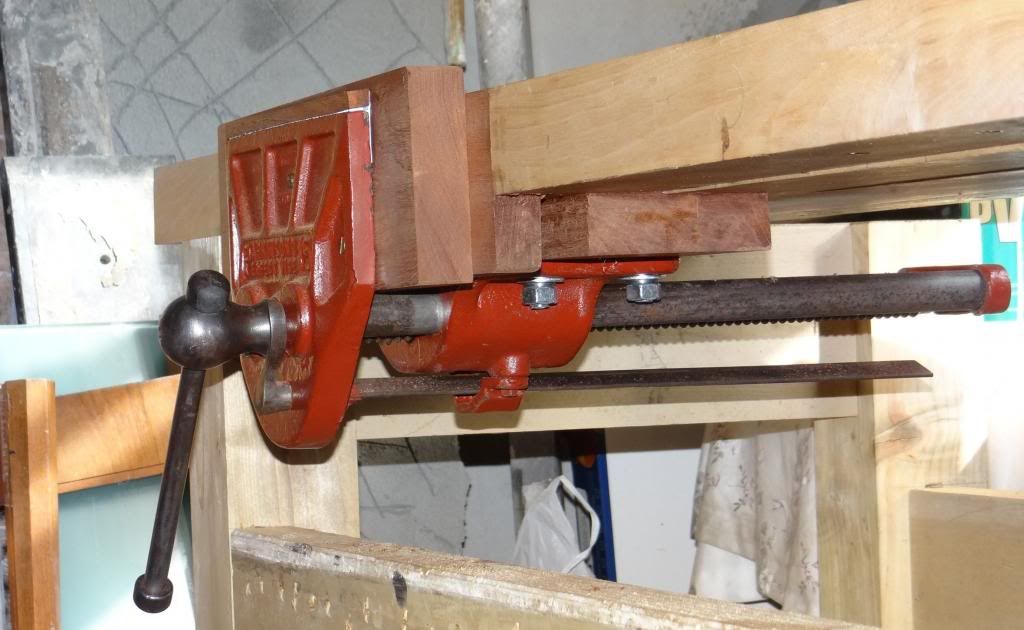

I have just finished fitting the front vice, a lovely old Parkinson Perfect no15, similar to a Record no52 1/2. It needed a bit of restoration and has cleaned up a treat. I used some offcuts of mahogany for the jaws and vice top covers.

The vice has a slight angle to the jaws so top touches first then clamps down. With the linings in, the opening is eleven inches. Enough for 99% of all work.

I used coach bolts to fix the vice, they give a really solid fixing and don't work loose, as coach screws sometimes tend to do.

I'll update as and when the project moves on.

This was the first trial assembly, the joints are mortise and tennon, which will be pegged. the holes in the main member are from nails, I will fill them in and sand down to finish off.

I did not use through tennons, with pegs I thought it would be plenty strong enough and looks better. The stretchers are flush with the top of the leg to support the top.

The front part of the top is made of three inch thick beech with a pine length at the back, then I will put a tool well at the rear. The top has been mortise and tennoned onto the legs

I will use wedges to fix the tennons in the top.

I have just finished fitting the front vice, a lovely old Parkinson Perfect no15, similar to a Record no52 1/2. It needed a bit of restoration and has cleaned up a treat. I used some offcuts of mahogany for the jaws and vice top covers.

The vice has a slight angle to the jaws so top touches first then clamps down. With the linings in, the opening is eleven inches. Enough for 99% of all work.

I used coach bolts to fix the vice, they give a really solid fixing and don't work loose, as coach screws sometimes tend to do.

I'll update as and when the project moves on.