DaWoodster

Established Member

I think it's about time I posted something as I have been leeching advice for a few weeks now.

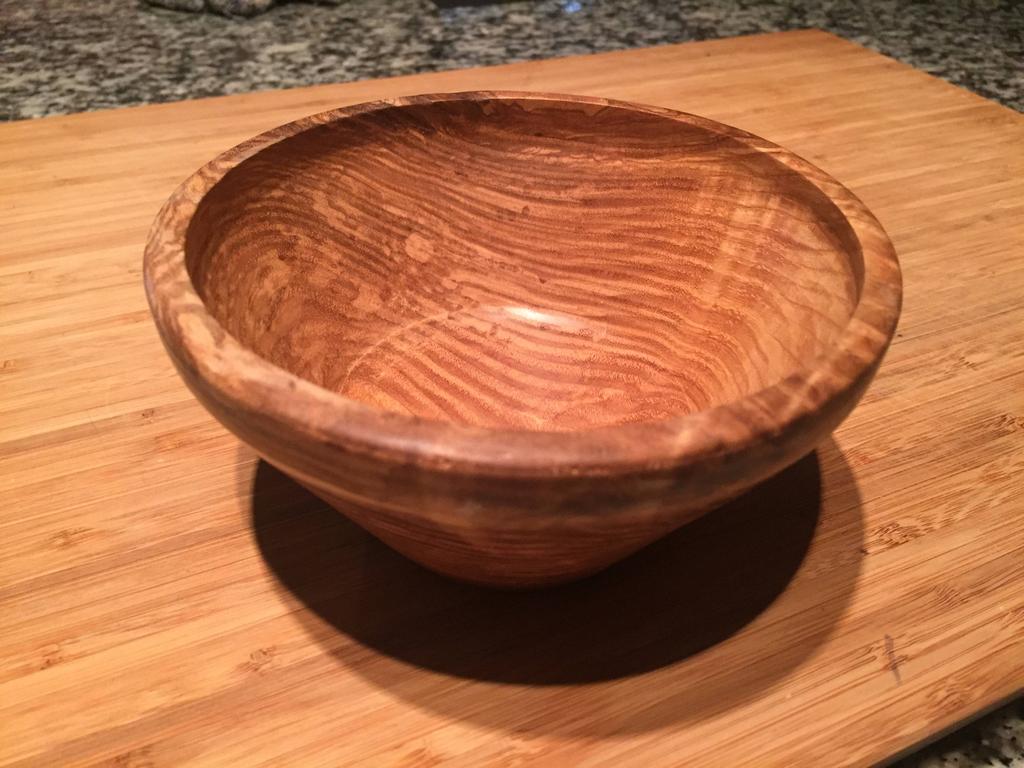

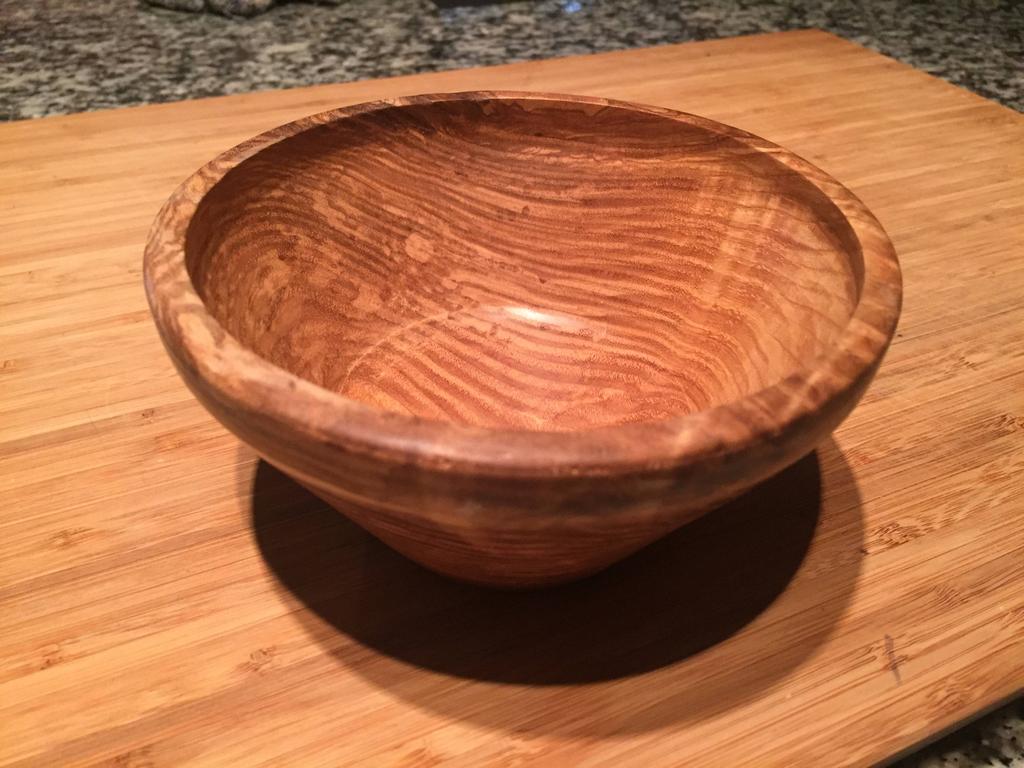

I just purchased my first lathe, a DML305-VS (thanks Gerry) and the first pieces fell off it this weekend.

Bowl #1 - Ash

Bowl #2 - Ash

Apple #1 - Ash

I am in Chatburn near Clitheroe Lancashire, if any locals know good sources of wood or even a decent local tool shop i'd appreciate the advice

Paul.

I just purchased my first lathe, a DML305-VS (thanks Gerry) and the first pieces fell off it this weekend.

Bowl #1 - Ash

Bowl #2 - Ash

Apple #1 - Ash

I am in Chatburn near Clitheroe Lancashire, if any locals know good sources of wood or even a decent local tool shop i'd appreciate the advice

Paul.