Noel":1o3c1nwi said:

Ollie, great job, lovely looking piece, and just ignore the grumpy old moaners.

If it's me your'e referring to, I'll ignore that.

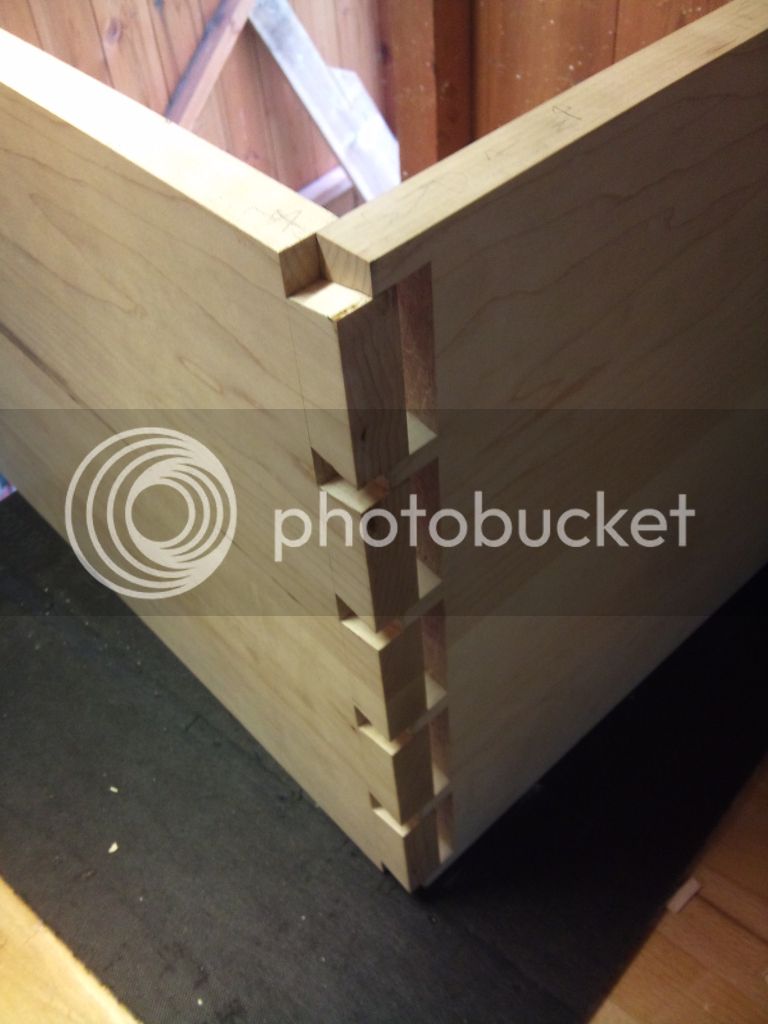

Dovetails. Yep, the job is probably designed to sit on a surface and so won't be lifted. However, imagine that it was a toolbox (with a handle on the top) that was designed to be toted around from place to place (as lots of toolboxes are) then the weight of the tools inside will tend to pull the joints apart (as shown in the pics) because there's no 'wedge' action to keep it in place. All that's resisting a downward force at the moment is the glue, there's no mechanical 'wedge' to hold the thing in place...if the glue failed, the job would fall apart! It's something I used to demonstrate to the kids when I was teaching many moons ago...the idea of a d/t is to resist force in one direction, so that if an attempt is made to pull the joint apart

against the dovetail it will simply get tighter, it won't come apart. What I used to do was to get the biggest and ugliest student to try and pull a correctly made, dry (no glue) single dovetail apart...it never happened, even with soft mushy pine - Rob