swagman

Established Member

Recent purchase from the uk. This natural stone was in fairly rough condition when I received it. Concavity on both flats with reasonably deep grooves suggesting it had been used at some stage with narrow chisels and/or a variety of carving chisels. Stone measures 20cm x 5.5cm x 2.5cm. Its of medium hardness close to 8000 grit, and exhibits an off white to brown slurry. It reminds me a lot of a modern mined German Muller stone, but of a much earlier period in time. Its possibly a Blue Thuringian. https://www.griffithshavinggoods.com...nt=25756010056

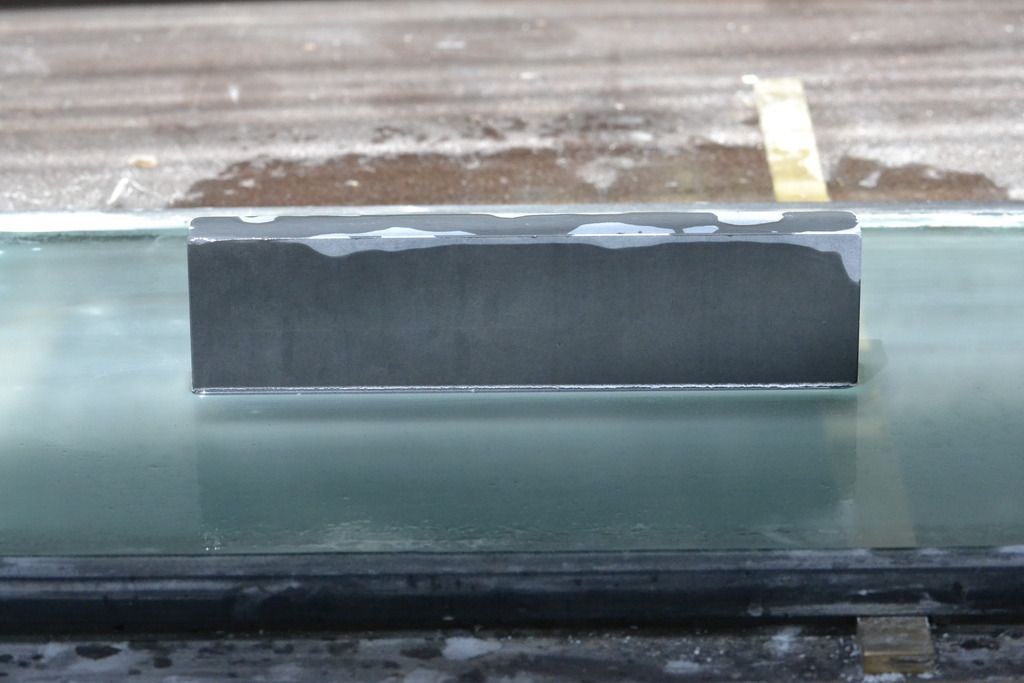

The following photo shows the colour after being freshly flattened with sic 280.

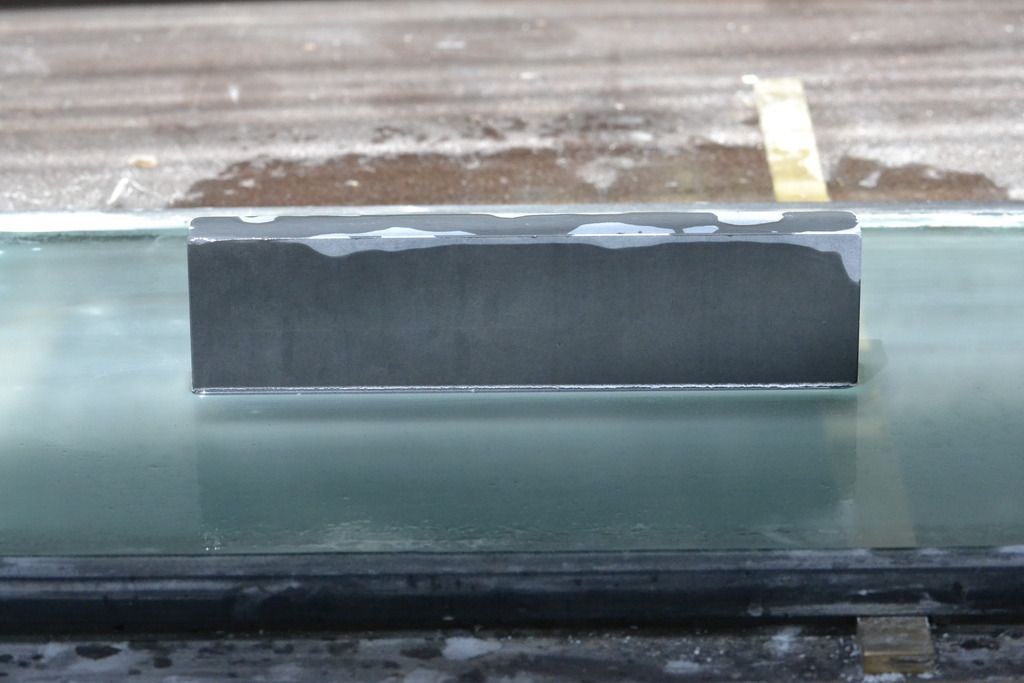

The next photo shows the colour of the stone after 24 hrs of being flattened. (Same colour as originally received).

The final photo shows the stones slurry after been worked with a chisel.

I should make mention that the lubricant used is water. Another feature of this stone is that if not enough water is maintained on the top surface of the stone, the stones surface if prone to fine scratches when the pressure applied by the cutting edge of the tool is not kept even. Not a big deal as these scratches can be later removed by rubbing the surface on a float glass of 400 grit wet & dry, but it does emphasize that some stones are more prone to a higher maintenance than others based on their surface hardness.

Stewie;

The following photo shows the colour after being freshly flattened with sic 280.

The next photo shows the colour of the stone after 24 hrs of being flattened. (Same colour as originally received).

The final photo shows the stones slurry after been worked with a chisel.

I should make mention that the lubricant used is water. Another feature of this stone is that if not enough water is maintained on the top surface of the stone, the stones surface if prone to fine scratches when the pressure applied by the cutting edge of the tool is not kept even. Not a big deal as these scratches can be later removed by rubbing the surface on a float glass of 400 grit wet & dry, but it does emphasize that some stones are more prone to a higher maintenance than others based on their surface hardness.

Stewie;