Hello,

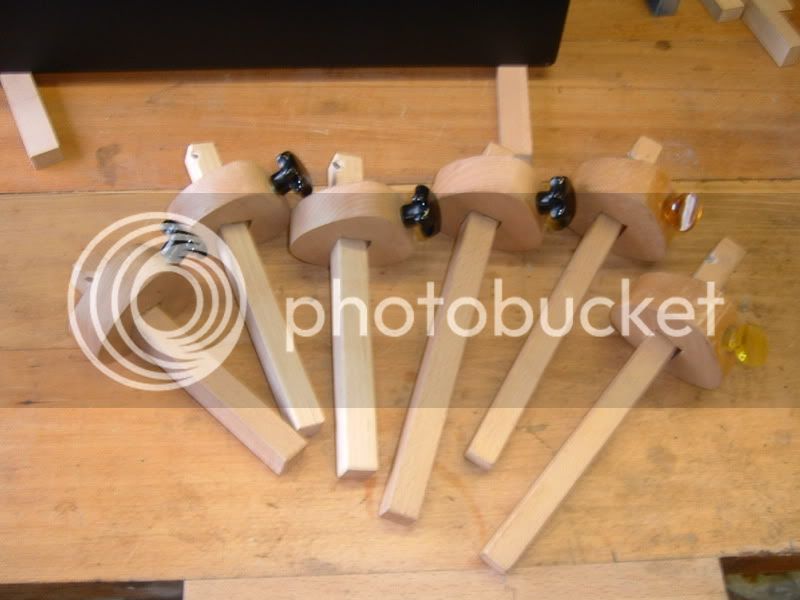

I am after a bit of advice, this is a veneer slicer that I recently made, the design is borrowed from a well-known American company!

It generally works well, and I like the fact that the locking mechanism clamps the shaft into the ‘V’ of the square hole in the fence. I’m going to make a few more tools that work on the same principle but would like to know if there is a good way of producing an accurate square hole with sides square to the face?

I chiseled this one out with a bevel edged chisel whilst eyeing a square, and although it works, it doesn’t bare close scrutiny, and needed a fair bit of fettling. My preference is to do it with hand tools as it is my hand tool skills I want to improve.

One idea I had was to cut the wood in half and cut out a right angle triangle in each section and then glue the two pieces back together again. Aesthetically this isn’t as appealing, but it is a tool after all and function over aesthetics will win.

Would a mortise chisel produce a more accurate cut over a bevel edged chisel?

Any ideas would be gratefully received,

Best wishes,

Chris

I am after a bit of advice, this is a veneer slicer that I recently made, the design is borrowed from a well-known American company!

It generally works well, and I like the fact that the locking mechanism clamps the shaft into the ‘V’ of the square hole in the fence. I’m going to make a few more tools that work on the same principle but would like to know if there is a good way of producing an accurate square hole with sides square to the face?

I chiseled this one out with a bevel edged chisel whilst eyeing a square, and although it works, it doesn’t bare close scrutiny, and needed a fair bit of fettling. My preference is to do it with hand tools as it is my hand tool skills I want to improve.

One idea I had was to cut the wood in half and cut out a right angle triangle in each section and then glue the two pieces back together again. Aesthetically this isn’t as appealing, but it is a tool after all and function over aesthetics will win.

Would a mortise chisel produce a more accurate cut over a bevel edged chisel?

Any ideas would be gratefully received,

Best wishes,

Chris