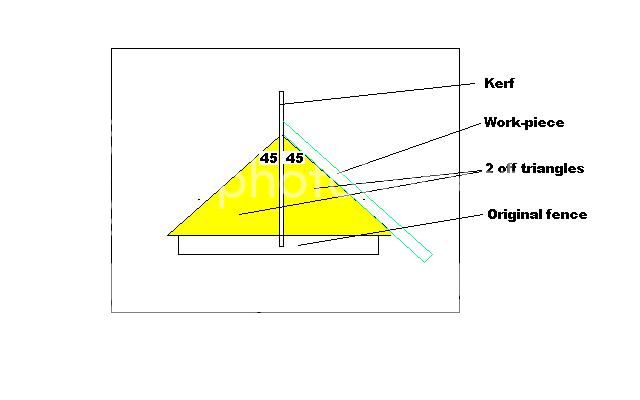

This will be childs play to most of you but I made a false table for my bandsaw yesterday so I can cut up my small pieces of wood safely and quickly.

My Dad told me what I needed to make and I was pretty pleased with my hours work.

I can now cut up my strips of jelutong in minutes.

A small modification to the photos was to add a scale on the wood to clamp to so I could cut the pieces to length (3" in this case) quickly.

Much more accurate than using a mitre box and hand saw and so much quicker

It is made from a scrap of MDF I had, a scrap of beech that was already exactly the right thickness for the mitre slot on the bandsaw table which I cut to width and a cheap pen blank.

I hope the images work ok!

False_table_top by jensmith25y,

False_table_slot by jensmith25y, on Flickr

False table underside by jensmith25y, on Flickr

Jennifer,

My Dad told me what I needed to make and I was pretty pleased with my hours work.

I can now cut up my strips of jelutong in minutes.

A small modification to the photos was to add a scale on the wood to clamp to so I could cut the pieces to length (3" in this case) quickly.

Much more accurate than using a mitre box and hand saw and so much quicker

It is made from a scrap of MDF I had, a scrap of beech that was already exactly the right thickness for the mitre slot on the bandsaw table which I cut to width and a cheap pen blank.

I hope the images work ok!

False_table_top by jensmith25y,

False_table_slot by jensmith25y, on Flickr

False table underside by jensmith25y, on Flickr

Jennifer,