mikec

Established Member

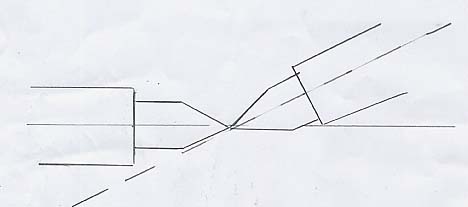

I remember seeing somewhere on the Web a metal rod that had a 1MT on each end. It went into the head and tailstock of a swivel head lathe as an alignment aid when re-aligning the centres.

Does anybody remember seeing something similar or know where I can get one :?:

Mike C

Does anybody remember seeing something similar or know where I can get one :?:

Mike C