slightspirit

New member

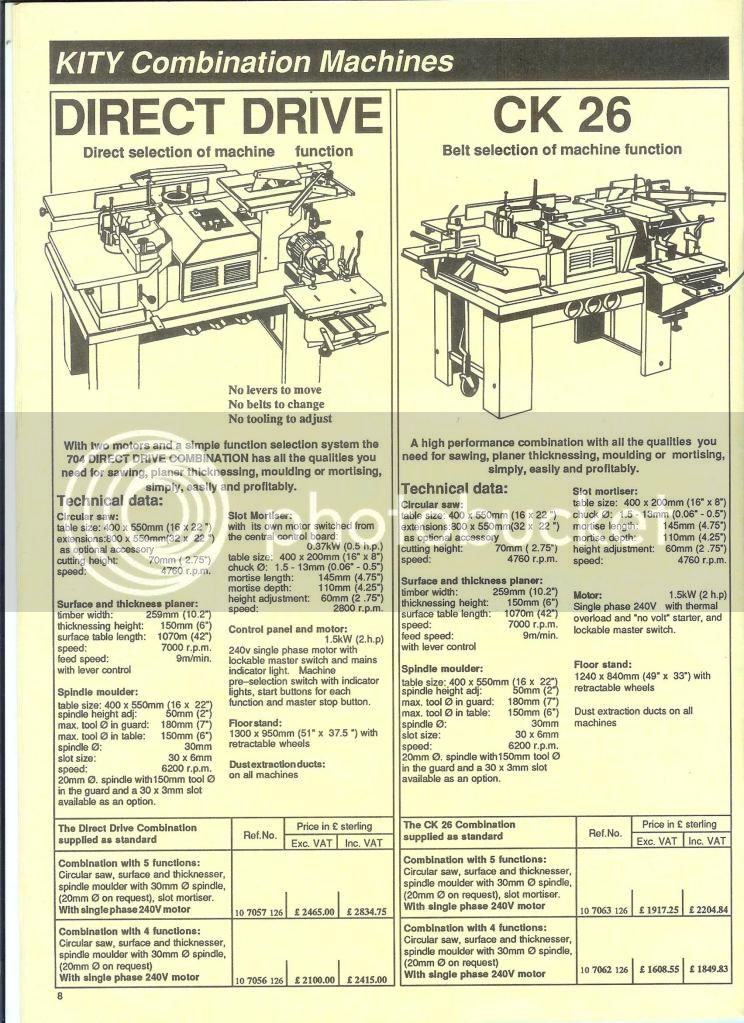

Hello I have just joined the forum! I came across it in my desperate search for help with my newly acquired, oldish Kity combi. the label on the side informs me that it is a direct drive! well I have never had anything to do with machines of this type before. It is a table saw, planer/thicknesser, molder, morticer. Three of them run off a central motor via two belts. the morticer has its own motor.

My problem is... recently the table saw and the planer stopped working! The motor still runs and the molder still works.

To select each unit you turn a central switch which appears to operate a solenoid which in turn engages a magnetic clutch on the direct[central drive shaft]. On inspecting the control box there appears only to be one solenoid, which works when selecting the molder. It all points to the switch, but because it effects the planer as well I'm confused! Not being particularly electrically literate. Does anyone have any knowledge of these machines and what could be the problem?

Thanks in anticipation [Hopefully]

Slightspirit

My problem is... recently the table saw and the planer stopped working! The motor still runs and the molder still works.

To select each unit you turn a central switch which appears to operate a solenoid which in turn engages a magnetic clutch on the direct[central drive shaft]. On inspecting the control box there appears only to be one solenoid, which works when selecting the molder. It all points to the switch, but because it effects the planer as well I'm confused! Not being particularly electrically literate. Does anyone have any knowledge of these machines and what could be the problem?

Thanks in anticipation [Hopefully]

Slightspirit