Hello, I am a complete novice to the world of woodworking, wood specie, soft & hard woods, their structural grades and intended construction use for the specie chosen for a particular construction role.

The reason I am writing this, is to share and hopefully offer awareness from my somewhat nieve blindness and trusting faith in timber suppliers, their knowledge and understanding of timber and chemical treatments, after all they are supposed to know what they are selling, and the advice given, right ? You'd think so, in my case, sadly not, what you want from the timber for the particular construction role, and my very first construction attempt.

This is my very first effort at any type of timber construction, thankfully nothing that is going to hurt anybody.

At the beginning of the year, I decided for my dogs health, to purchase a self contained Hydrotherapy pool, (hot tub without seats) once I had the dimensions and weights, I set about turning my garden into a building site, I must say this before anyone says, concrete, I do NOT like concrete, especially concrete bases, so armed with a head full of ideas, I decided that I wanted a finish base height level with my remaining lawn, this meant I had to dig down to lay a foundation base to support a timber frame base.

Let the digging commence.

This is where the first of the issues dawned upon me, the timber will be below surrounding garden level, so with that realisation, I knew whatever type of timber I ordered would need protecting, anyway on with digging.

Once the digging was complete, down as far as the clay base level, a stone hardcore was used, compacted whacked flat, quarry sand was compacted and whacked flat on top of the stone hardcore to create a very solid level base from which to lay and support the commercial 18" x 18" x 3" concrete paving slabs, I hate concrete, but when they are free, mustn't grumble.

Once the foundation base had been laid, I then turned my attention to the timber base, which would support the Hydrotherapy pool, whilst also needing to be chemically treated, as if you remember, the issue of below ground level was now more apparent after a very heavy down pour (14 hours continuously) oops the clay base was now doing its job, yes, my base was holding 1/2 inch of water across the entire base site, at least I know it's level.

At this stage of my very first construction attempt, I'm now getting quite a few very different opinions on what I should do, given that the Hydrotherapy pool weighs 5 tonnes when full of water, most said I needed to contract the services of a structural engineer, which I thought was over the top, after all how many people sit their hot tubs on regular decking !!

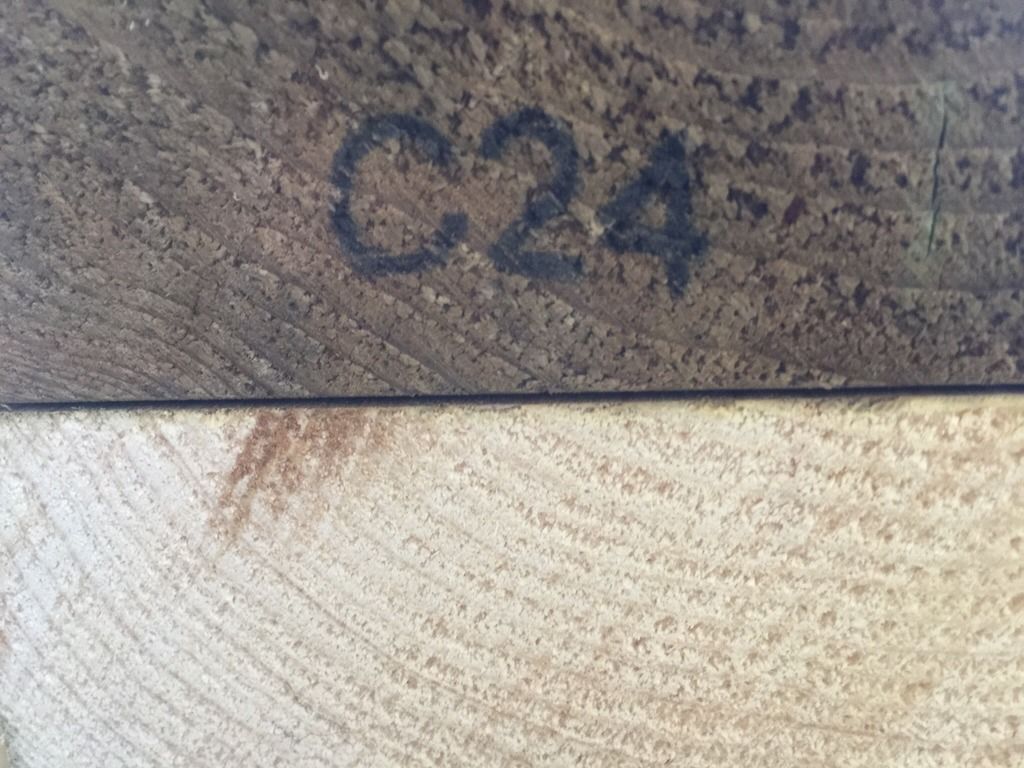

Regardless of the advice to contract a structural engineer, I used my engineering (Motorsport) and common sense approach to work it out myself, albeit with advice from the timber supplying company, I ordered construction grade C24 with the class 4 ground contact chemical treatment, now what I wasn't aware of and had no advice that dependant on the different specie of wood and whether it's sap or heartwood and the moisture content, controls the % of chemical treatment ingress depth penetration.

This I wasn't aware of, and when my treated timber arrived, it looked very impressive, however, when I started to work with it, I became very suspicious to the treatment my ordered timber had been subject to, I also wasn't aware that treated timber is certified, given my concerns I contacted the timber suppliers and was told that chemical treatment doesn't ingress the timber fully, that said, I formed them my timber seemed to have just surface contact only with no ingress penetration.

Rather than argue, I contacted the chemical treatment manufacturers, they have been incredibly helpful and supportive, they asked for samples of my treated timber, the results of analysis confirmed my suspicions, the timber I was sold and was treated is not receptive to chemical treatment, and the company who treated the timber, should have known that the particular timber offered for treatment was not receptive, and would only have a surface coating, rendering the timber useless for my particular intention of ground contact.

Needless to say I am now in never ending talks, even with supported evidence to either get the timber replaced or a full refund, so I can continue with my project, very frustrating indeed, what I will say is, anyone purchasing treated timber or having timber treated, be very aware that varying timber specie, sap and heartwood have varying levels of % ingress penetration of chemical treatment,

The reason I am writing this, is to share and hopefully offer awareness from my somewhat nieve blindness and trusting faith in timber suppliers, their knowledge and understanding of timber and chemical treatments, after all they are supposed to know what they are selling, and the advice given, right ? You'd think so, in my case, sadly not, what you want from the timber for the particular construction role, and my very first construction attempt.

This is my very first effort at any type of timber construction, thankfully nothing that is going to hurt anybody.

At the beginning of the year, I decided for my dogs health, to purchase a self contained Hydrotherapy pool, (hot tub without seats) once I had the dimensions and weights, I set about turning my garden into a building site, I must say this before anyone says, concrete, I do NOT like concrete, especially concrete bases, so armed with a head full of ideas, I decided that I wanted a finish base height level with my remaining lawn, this meant I had to dig down to lay a foundation base to support a timber frame base.

Let the digging commence.

This is where the first of the issues dawned upon me, the timber will be below surrounding garden level, so with that realisation, I knew whatever type of timber I ordered would need protecting, anyway on with digging.

Once the digging was complete, down as far as the clay base level, a stone hardcore was used, compacted whacked flat, quarry sand was compacted and whacked flat on top of the stone hardcore to create a very solid level base from which to lay and support the commercial 18" x 18" x 3" concrete paving slabs, I hate concrete, but when they are free, mustn't grumble.

Once the foundation base had been laid, I then turned my attention to the timber base, which would support the Hydrotherapy pool, whilst also needing to be chemically treated, as if you remember, the issue of below ground level was now more apparent after a very heavy down pour (14 hours continuously) oops the clay base was now doing its job, yes, my base was holding 1/2 inch of water across the entire base site, at least I know it's level.

At this stage of my very first construction attempt, I'm now getting quite a few very different opinions on what I should do, given that the Hydrotherapy pool weighs 5 tonnes when full of water, most said I needed to contract the services of a structural engineer, which I thought was over the top, after all how many people sit their hot tubs on regular decking !!

Regardless of the advice to contract a structural engineer, I used my engineering (Motorsport) and common sense approach to work it out myself, albeit with advice from the timber supplying company, I ordered construction grade C24 with the class 4 ground contact chemical treatment, now what I wasn't aware of and had no advice that dependant on the different specie of wood and whether it's sap or heartwood and the moisture content, controls the % of chemical treatment ingress depth penetration.

This I wasn't aware of, and when my treated timber arrived, it looked very impressive, however, when I started to work with it, I became very suspicious to the treatment my ordered timber had been subject to, I also wasn't aware that treated timber is certified, given my concerns I contacted the timber suppliers and was told that chemical treatment doesn't ingress the timber fully, that said, I formed them my timber seemed to have just surface contact only with no ingress penetration.

Rather than argue, I contacted the chemical treatment manufacturers, they have been incredibly helpful and supportive, they asked for samples of my treated timber, the results of analysis confirmed my suspicions, the timber I was sold and was treated is not receptive to chemical treatment, and the company who treated the timber, should have known that the particular timber offered for treatment was not receptive, and would only have a surface coating, rendering the timber useless for my particular intention of ground contact.

Needless to say I am now in never ending talks, even with supported evidence to either get the timber replaced or a full refund, so I can continue with my project, very frustrating indeed, what I will say is, anyone purchasing treated timber or having timber treated, be very aware that varying timber specie, sap and heartwood have varying levels of % ingress penetration of chemical treatment,