Aragorn

Established Member

Hello!!

Hope you're all well.

Please could I cheekily ask for a little help with a problem...

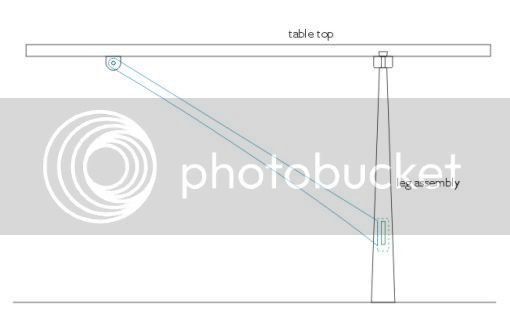

Here's a project I'm working on. A kitchen table that needs a knock down stretcher. This is an image of part of the leg assembly:

I hope you can make that out.

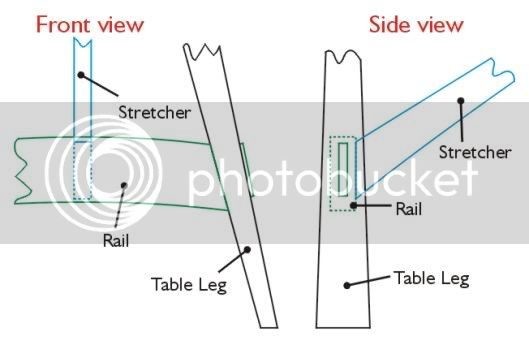

See the blue stretcher?? That needs to fix into the green rail easily and very securely, but also be removeable, so that it can be knocked down.

Any ideas what kind of joint to use?? Or ideas for some other way of attaching it??

Hope you're all well.

Please could I cheekily ask for a little help with a problem...

Here's a project I'm working on. A kitchen table that needs a knock down stretcher. This is an image of part of the leg assembly:

I hope you can make that out.

See the blue stretcher?? That needs to fix into the green rail easily and very securely, but also be removeable, so that it can be knocked down.

Any ideas what kind of joint to use?? Or ideas for some other way of attaching it??