shedhead

Established Member

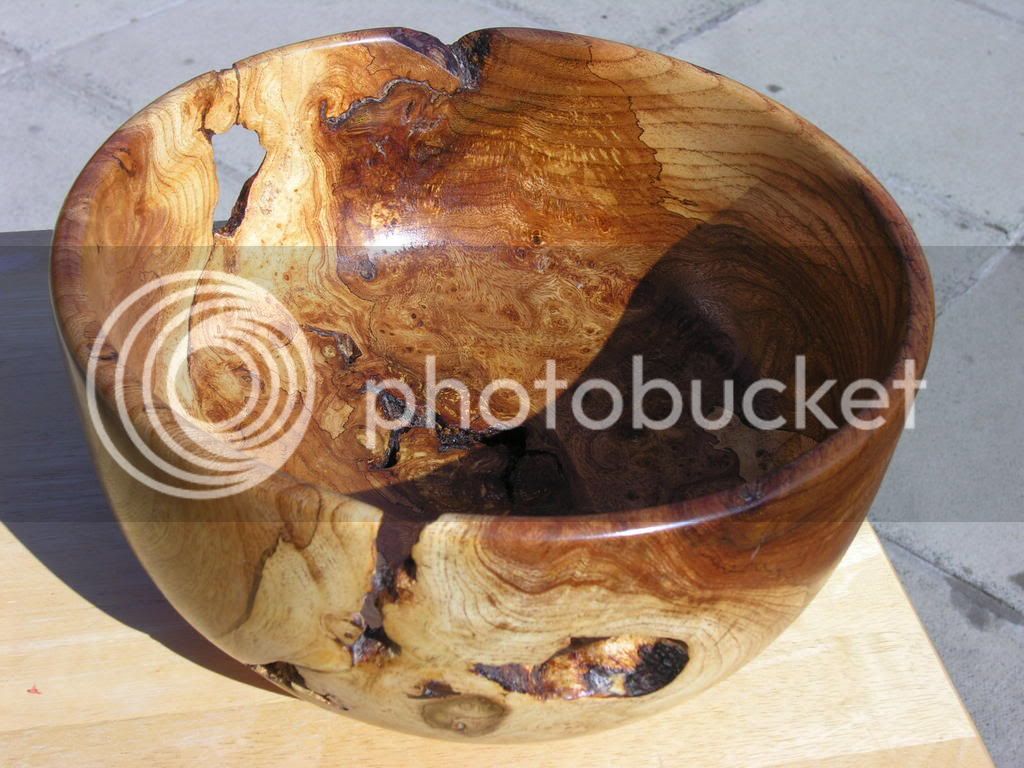

I have just turned a Elm Burr bowl, with some nice grain. I want to get a glass like finish as i think this will be the best look for this piece. It is approx 6" deep x 10" diameter, with bark inclusion and some small holes in it. I have put supper glue on some of the larger cracks just to give it added strength, but it should not move much as it was well dry.

Tomorrow i will add 50% sand & sealer and 50% thinner, as i always do. What other base can i add before i add final coat of friction polish?. Would adding boiled linseed oil before polish give it the glass look i want to achieve?.

Tomorrow i will add 50% sand & sealer and 50% thinner, as i always do. What other base can i add before i add final coat of friction polish?. Would adding boiled linseed oil before polish give it the glass look i want to achieve?.