memzey

Established Member

A few weeks ago I made my first sacrifice of a Sunday morning lie in to potter around the bric a brac of a local boot fair in pursuit of some decent, old and predominantly English made hand tools. My outcomes for that day are captured in another thread but suffice to say a bug was well and truly caught by yours truly and I haven't missed one since! Someone should have warned me I was on a slippery slope!!! Anyway I have since purchased much that I am truly please with but wanted to share the following items with my fellow board members for comment and review:

First up a really nice dovetail saw with a stamped mark of "Johnson Cast Steel"

I am not familiar with this maker - can anyone shed some light on it? It is well balanced and extremely comfortable in the hand.

Next up some set squares. The three smaller ones are Moore and Wright while the larger (6 inch) one is Rabone Chesterman:

They are all square inside and out as far as I can tell.

Next up is a very fine oil stone - much finer than the combi stone I picked up in my first outing. It feels almost like glass to the touch. I expertly dropped it to remove a chip from the corner thus revealing to you all the true colour of the stone:

Would anyone care to hazard a guess on the type of stone this one is? It has the hairs on my arm in quite a nervous state.

On the topic of stones: I picked up a mixed box of small stones. One of them is of triangle profile:

Could this be used to sharpen saws?

A really nice Sorby chisel

I have a feeling it's a bit younger than some of my earlier purchases. Anyone care to guess its age?

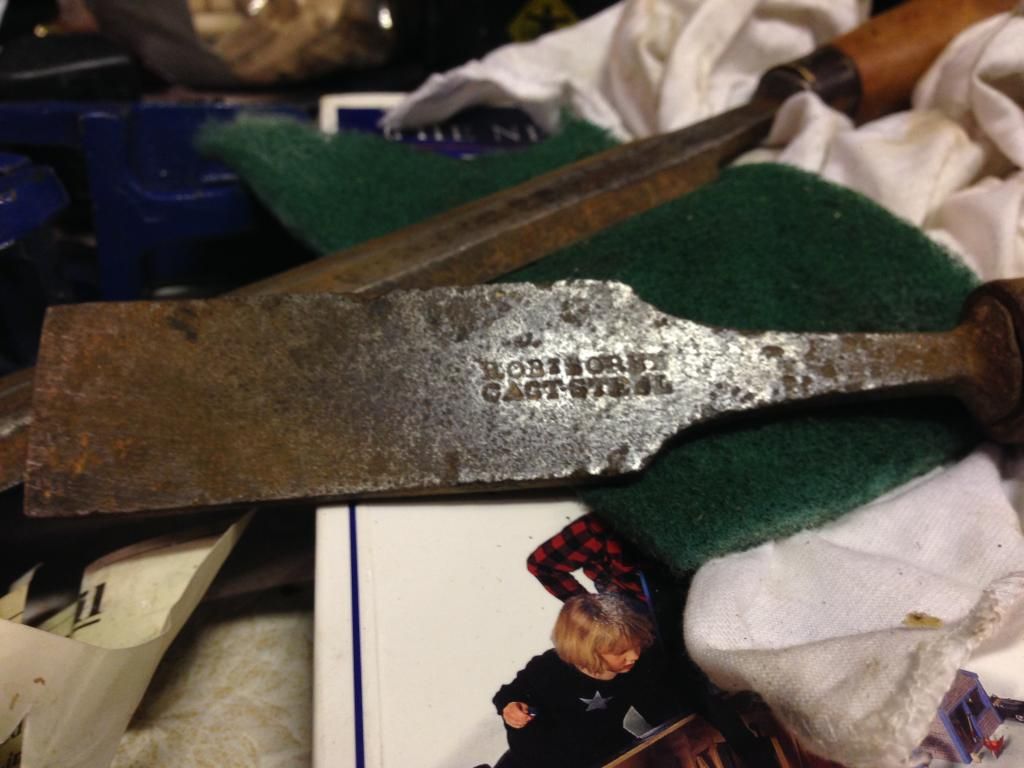

A "fabulous?" marking knife Again not a maker I'm aware of but would be glad to hear from someone who is.

Again not a maker I'm aware of but would be glad to hear from someone who is.

Mortise and bevel gauges from W Marples & Sons. These are in really good condition:

An unusual little vise which I have screwed to my work top. The threads actually run over the bench rather than under it which is a new one on me but not a problem. Cost me a fiver though so it's the priciest thing I've bought to date:

A couple of pairs of Record cramp heads (£1 each)

#4 and #5 Stanley hand planes with wooden totes and really nice, flat soles and square mouths:

The #4 has a screw missing for the back handle. Any ideas where I could get one?

From top to bottom; a wooden thing with a sharp metal bit I bought by accident, a cast steel Robt Sorby, a Marples and an awesome Ward and Payne: (I think this might be the best chisel I have bought so far)

Now for one I am really pleased even though I'm not entirely sure I know what it's for; my new/old Disston back saw:

Why, other than my regular ignorance, am I unsure what it's for? It's much bigger than any tennon saw I have seen before. It's a real lump but dead straight and well set. Is there another type of back saw that's bigger than a tennon of which I am unaware? Oh and as for why I'm particularly pleased with it; it has cleaned up an absolute treat:

Now a bit of a curiosity: I think it's a dovetail marking gauge - can anyone confirm? I think it was owner made as it has no makers mark:

So do we think there is anything in this lot that is interesting or is it all toot? Please bear in mind that apart from the vise (£5), the Disston (£2.50) and the Jack plane (also £2.50) everything was a pound or less.

First up a really nice dovetail saw with a stamped mark of "Johnson Cast Steel"

I am not familiar with this maker - can anyone shed some light on it? It is well balanced and extremely comfortable in the hand.

Next up some set squares. The three smaller ones are Moore and Wright while the larger (6 inch) one is Rabone Chesterman:

They are all square inside and out as far as I can tell.

Next up is a very fine oil stone - much finer than the combi stone I picked up in my first outing. It feels almost like glass to the touch. I expertly dropped it to remove a chip from the corner thus revealing to you all the true colour of the stone:

Would anyone care to hazard a guess on the type of stone this one is? It has the hairs on my arm in quite a nervous state.

On the topic of stones: I picked up a mixed box of small stones. One of them is of triangle profile:

Could this be used to sharpen saws?

A really nice Sorby chisel

I have a feeling it's a bit younger than some of my earlier purchases. Anyone care to guess its age?

A "fabulous?" marking knife

Mortise and bevel gauges from W Marples & Sons. These are in really good condition:

An unusual little vise which I have screwed to my work top. The threads actually run over the bench rather than under it which is a new one on me but not a problem. Cost me a fiver though so it's the priciest thing I've bought to date:

A couple of pairs of Record cramp heads (£1 each)

#4 and #5 Stanley hand planes with wooden totes and really nice, flat soles and square mouths:

The #4 has a screw missing for the back handle. Any ideas where I could get one?

From top to bottom; a wooden thing with a sharp metal bit I bought by accident, a cast steel Robt Sorby, a Marples and an awesome Ward and Payne: (I think this might be the best chisel I have bought so far)

Now for one I am really pleased even though I'm not entirely sure I know what it's for; my new/old Disston back saw:

Why, other than my regular ignorance, am I unsure what it's for? It's much bigger than any tennon saw I have seen before. It's a real lump but dead straight and well set. Is there another type of back saw that's bigger than a tennon of which I am unaware? Oh and as for why I'm particularly pleased with it; it has cleaned up an absolute treat:

Now a bit of a curiosity: I think it's a dovetail marking gauge - can anyone confirm? I think it was owner made as it has no makers mark:

So do we think there is anything in this lot that is interesting or is it all toot? Please bear in mind that apart from the vise (£5), the Disston (£2.50) and the Jack plane (also £2.50) everything was a pound or less.