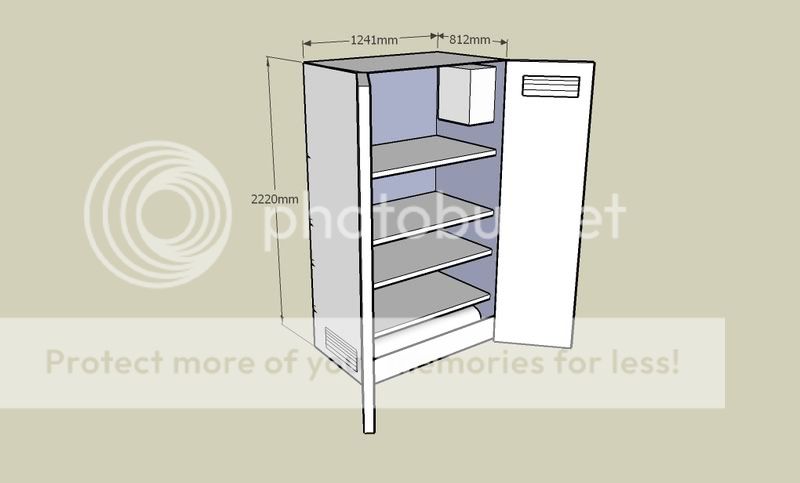

I'm about to build a drying cabinet in the workshop on the lines of that shown below:

I've read up as much as I can find on the web, everybody's pretty vague on it though.

Bottom left of the cabinet is an air 'intake' vent and on the Rt hand door is an 'extract' vent. The whole thing is heated by 2 x 300w tube heaters in the base, with a dehumidifier (...that box at the top) dragging the air in and pushing it out. The dehumidifier is permanently drained to a sink.

Construction is going to be 1/2" chipboard sandwiching Rockwool insulation.

The shelves aren't going to be solid. but slatted to aid circulation.

Anyone got any first hand experience of these/ think it's a non-starter or see any obvious design flaws?

.....and if I can figure it out the heaters will be thermostatically controlled.

Chris.

I've read up as much as I can find on the web, everybody's pretty vague on it though.

Bottom left of the cabinet is an air 'intake' vent and on the Rt hand door is an 'extract' vent. The whole thing is heated by 2 x 300w tube heaters in the base, with a dehumidifier (...that box at the top) dragging the air in and pushing it out. The dehumidifier is permanently drained to a sink.

Construction is going to be 1/2" chipboard sandwiching Rockwool insulation.

The shelves aren't going to be solid. but slatted to aid circulation.

Anyone got any first hand experience of these/ think it's a non-starter or see any obvious design flaws?

.....and if I can figure it out the heaters will be thermostatically controlled.

Chris.