You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

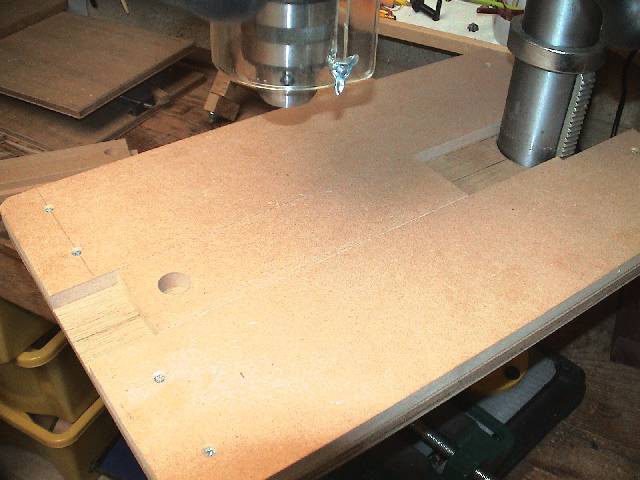

Drill press table for Byron

- Thread starter Lord Nibbo

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Fecn

Established Member

The aluminimum fence and locking stop block are excellent ideas - I've got aly like that in the garage and never once thought of using it for a fence.

Steve Maskery

Established Member

The nice thing about using Ali is that is is usually good on square. The downside is that it is quite easy to flex if you are applying pressure and it is unlikely to be big enough in section to take decent-sized knobs. My own preference is for Bristol levers. But for them you need at least 60mm clearance to from hole to fence, which is not easily available. Making a plywood fence gives you this flexibilty but with greater stabilty, I think.

I really do like like the drawer underneath though, I shall steal that!

Cheers

Steve

I really do like like the drawer underneath though, I shall steal that!

Cheers

Steve

Chris Knight

Established Member

Tom,

The circle is really smart - you get a new unspoilt surface to ensure a clean exit hole, just by rotating it a bit.

The circle is really smart - you get a new unspoilt surface to ensure a clean exit hole, just by rotating it a bit.

DaveL

Established Member

Its a sacrificial disc, that bit will get lots of centre marks and holes drilled in it, by making it round it can just be moved a few degrees and the support for the drill breaking thought id restored, helping to stop break out on the bottom of the work piece.WiZeR":3u1cnpr4 said:Am I silly? What's the point in the circle thingy?

doh beaten by Chris, must type quicker :roll:

Lord Nibbo

Established Member

waterhead37":3irkhb39 said:Tom,

The circle is really smart - you get a new unspoilt surface to ensure a clean exit hole, just by rotating it a bit.

Yes it really is a smart, that one idea is what first drew my attention.

Steve Maskery

Established Member

Actually, whilst I think that the idea of a sacrificial insert is essential, a disk seems to me to be too complex. You have to make a disk every time you need to change it. Surely much easier to have a sacrificial strip which is just ripped off the saw and slid up a bit each time. It's what I do, I'll try to remember to take a pic.

Cheers

Steve

Cheers

Steve

Topical post this one, as I'm in the process of completing work on my own drill press table.

Hope to finish work next weekend so will post some pictures. I have made it from an old kitchen door with some incra T track and fittings.

I have a square sacrificial insert, never thought of round - but can see the advantage.

- but can see the advantage.

Still I have not graduated to anything with a curve yet, let a lone a circle.

Esc.

Hope to finish work next weekend so will post some pictures. I have made it from an old kitchen door with some incra T track and fittings.

I have a square sacrificial insert, never thought of round

Still I have not graduated to anything with a curve yet, let a lone a circle.

Esc.

CHJ

Established Member

Steve Maskery":3bep9gy5 said:..... Surely much easier to have a sacrificial strip whick is just ripped off the saw and slid up a bit each time. It's what I do, I try to remember to take a pic.

Cheers

Steve

It's the method I chose on mine, and is certainly easier to replace.

woodbloke

Established Member

Steve Maskery":35wsf3p3 said:Actually, whilst I think that the idea of a sacrificial insert is essential, a disk seems to me to be too complex. You have to make a disk every time you need to change it. Surely much easier to have a sacrificial strip whick is just ripped off the saw and slid up a bit each time. It's what I do, I try to remember to take a pic.

Cheers

Steve

I do something similar to Steve. The pillar drill table has three parallel bits of 15mm mdf on it, the two outer ones are bolted down and the middle on is a tight sliding fit...this is the sacrificial one and once it gets too mangled it's easy to replace with another bit, in fact I keep a few in a drawer close by...works for me

Edit - and Chas :lol: - Rob

Steve Maskery

Established Member

CHJ":36ranl2z said:It's the method I chose on mine, and is certainly easier to replace.

Yep, same as mine (only mine is 6mm) and much easier than faffing around with discs.

I'll grant you it looks neat and tidy though, what with the edging and all - mine's not quite so chic.

S

ByronBlack

Established Member

Nibbo - thanks for re-finding this link, i'll make sure to bookmark it this time

Similar threads

- Replies

- 13

- Views

- 2K

- Replies

- 37

- Views

- 3K

- Replies

- 17

- Views

- 908