Sawdust=manglitter

Established Member

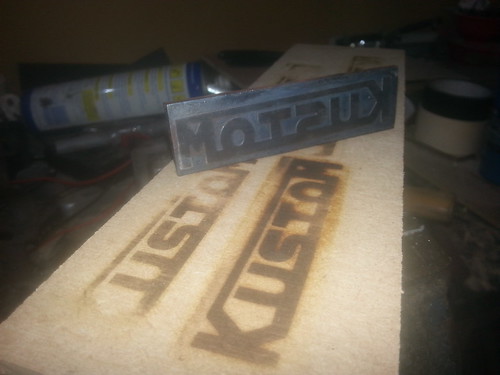

I fancy making my own branding iron (maybe a couple of sizes) to use on completed projects.

I saw the below video on the tube of a guy using a dremel to cut the aluminium to the shape of his design...

https://youtu.be/oV183DxKgg8

My question is, does anyone have experience or can recomend the best bits to use in the dremel for cutting aluminium (obviously a little at a time)? Ideally I'll need a larger bit to hog out most waste and tidy open areas, i'll need a smaller/pointy bit to tidy up sharp corners and a more general not as small bit for the majority of the shaping.

Would the cheap readily available Chinese HSS bits on eBay suffice?

When I get round to starting the branding iron I may do a WIP if anyone was interested.

I saw the below video on the tube of a guy using a dremel to cut the aluminium to the shape of his design...

https://youtu.be/oV183DxKgg8

My question is, does anyone have experience or can recomend the best bits to use in the dremel for cutting aluminium (obviously a little at a time)? Ideally I'll need a larger bit to hog out most waste and tidy open areas, i'll need a smaller/pointy bit to tidy up sharp corners and a more general not as small bit for the majority of the shaping.

Would the cheap readily available Chinese HSS bits on eBay suffice?

When I get round to starting the branding iron I may do a WIP if anyone was interested.